Welding Titanium

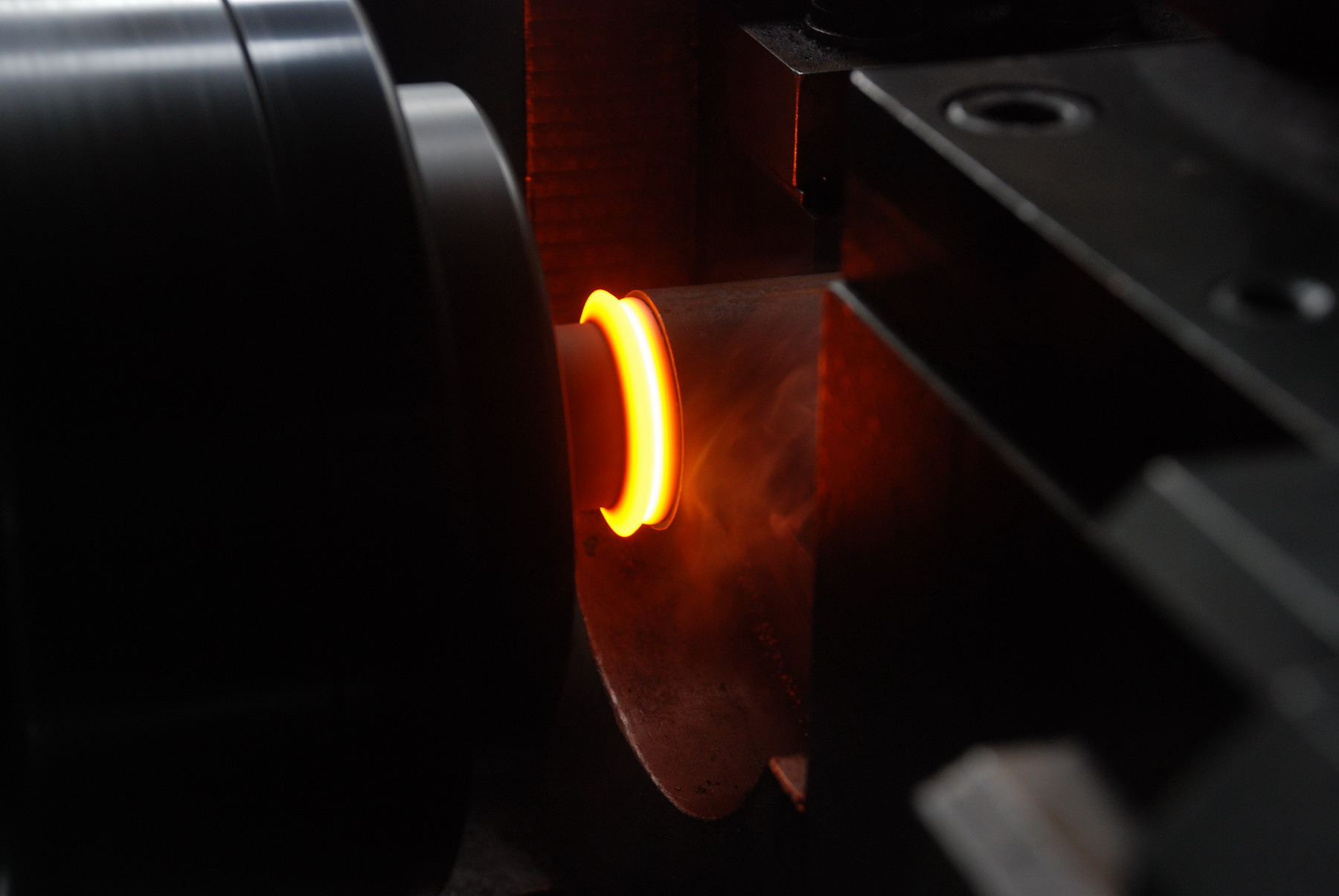

Titanium and most titanium alloys are readily weldable, using several welding processes. Properly made welds in the as-welded condition are ductile and, in most environments, are as corrosion resistant as base metal. Improper welds, on the other hand, might be embrittled and less corrosion-resistant compared to base metal.

Titanium need not be all that hard to weld

Titanium need not be all that hard to weld

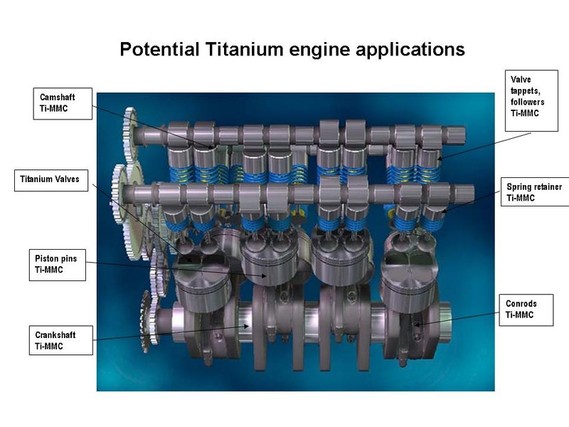

Commercially pure titanium and most titanium alloys are readily welded by a number of welding processes being used today. The most common method of joining titanium is the gas tungsten-arc (GTAW) process and, secondarily, the gas metal-arc (GMAW) process. Others include electron beam and more recently laser welding as well as solid state processes such as friction welding and diffusion bonding. Titanium and its alloys also can be joined by resistance welding and by brazing.

You might also like

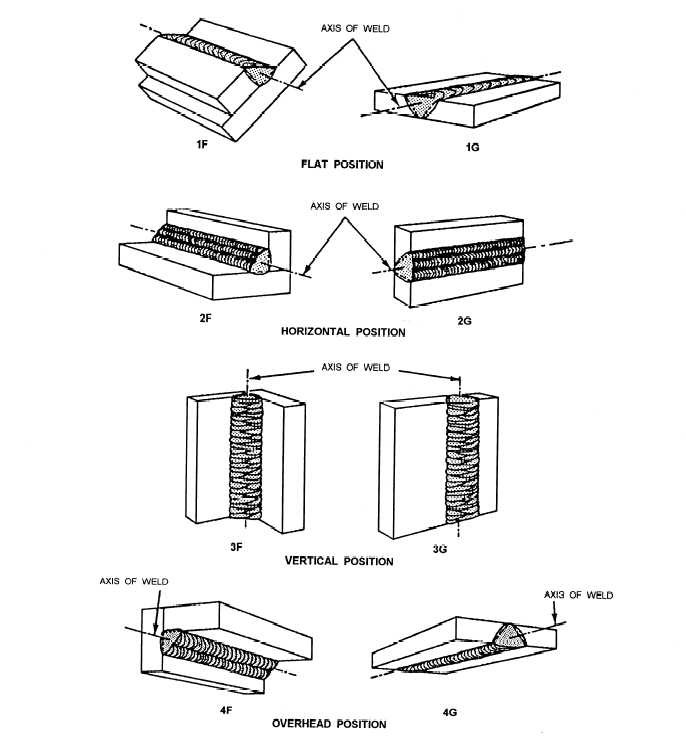

| How does Friction Welding Work ? What is Friction Welding ? Friction welding... | Welding Positions What`s Kind of Welding Positions ? Welding... | Titanium and Titanium Alloys What is Tinanium Alloys ? Titanium was... | How is Titanium made? How is Titanium made ? Titanium is known... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope