Metal spraying is spraying hot metal on to a surface to create a coating. Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The “feedstock” (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).

Metal spraying

Metal spraying

Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites.

You might also like

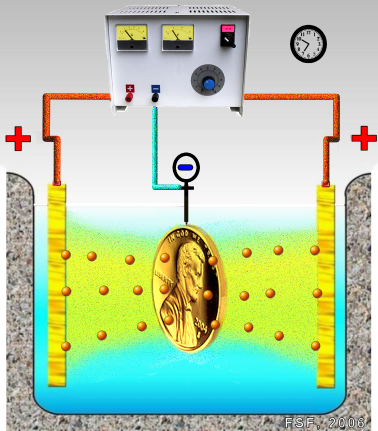

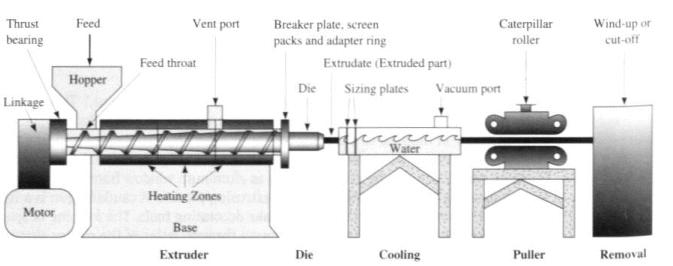

| Nano Coatings The nano coatings, "liquid solids"... | Electroplating Electroplating is the process of... | Extrusion Extrusion is the process by which... | Aluminum alloy Aluminum Alloy Wheel An alloy is a material... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope