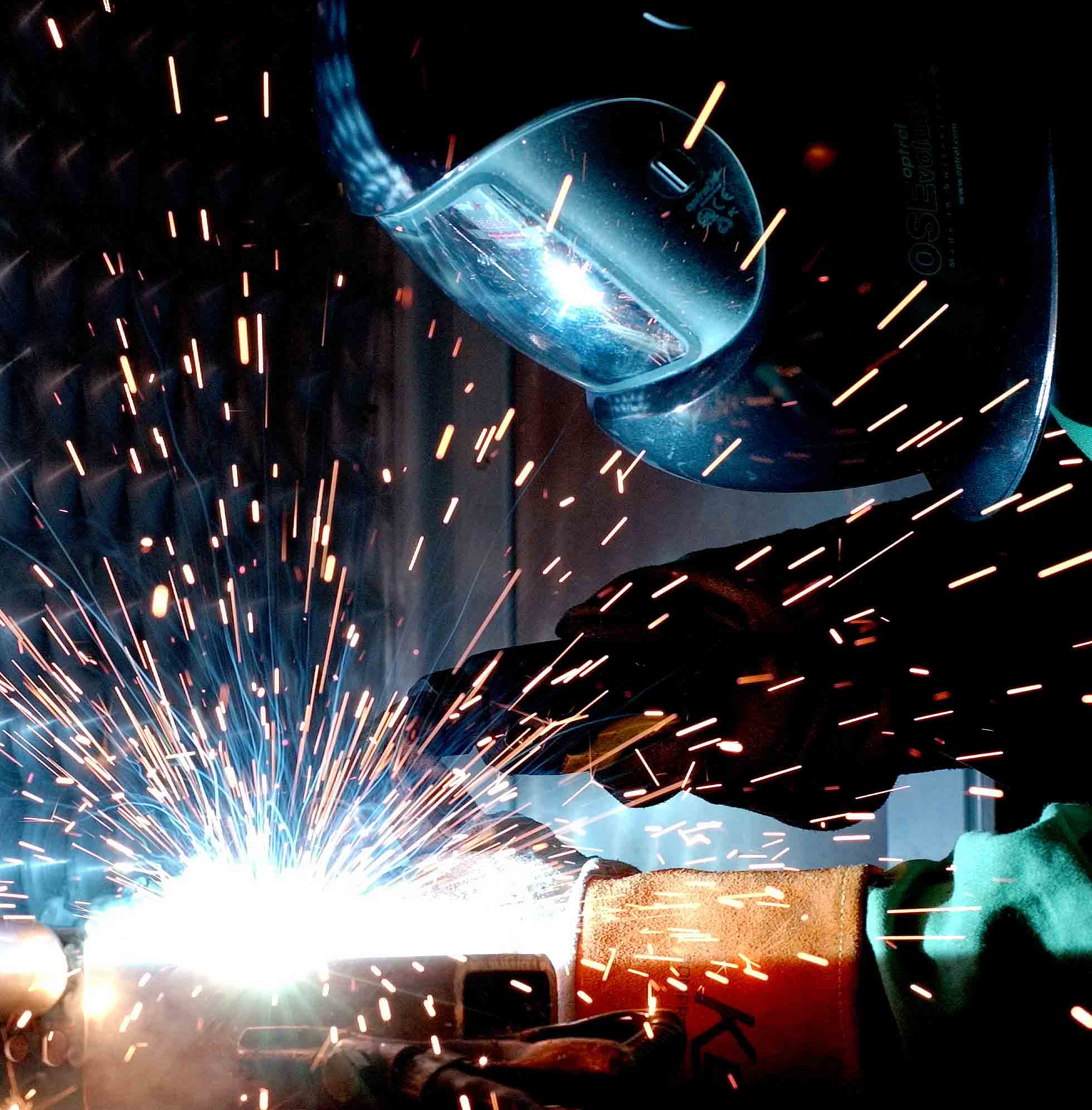

Spot Welding

Spot welding is a technique generally used to bond metals shaped into sheets no thicker than 3 millimeters. Unlike other welding techniques, spot welding can create precise bonds without generating excessive heating that can affect the properties of the rest of the sheet. This is achieved by delivering a large amount of energy in a short time in order to create controlled and reliable welds.

Robotic Spot Welding

Spot welding is a process in which contacting metal surfaces are joined by the heat obtained from resistance to electric current flow. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the 0.5 to 3 mm (0.020 to 0.12 in) thickness range. The process uses two shaped copper alloy electrodes to concentrate welding current into a small “spot” and to simultaneously clamp the sheets together. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is a lot of energy can be delivered to the spot in a very short time (approximately ten milliseconds). That permits the welding to occur without excessive heating to the rest of the sheet.

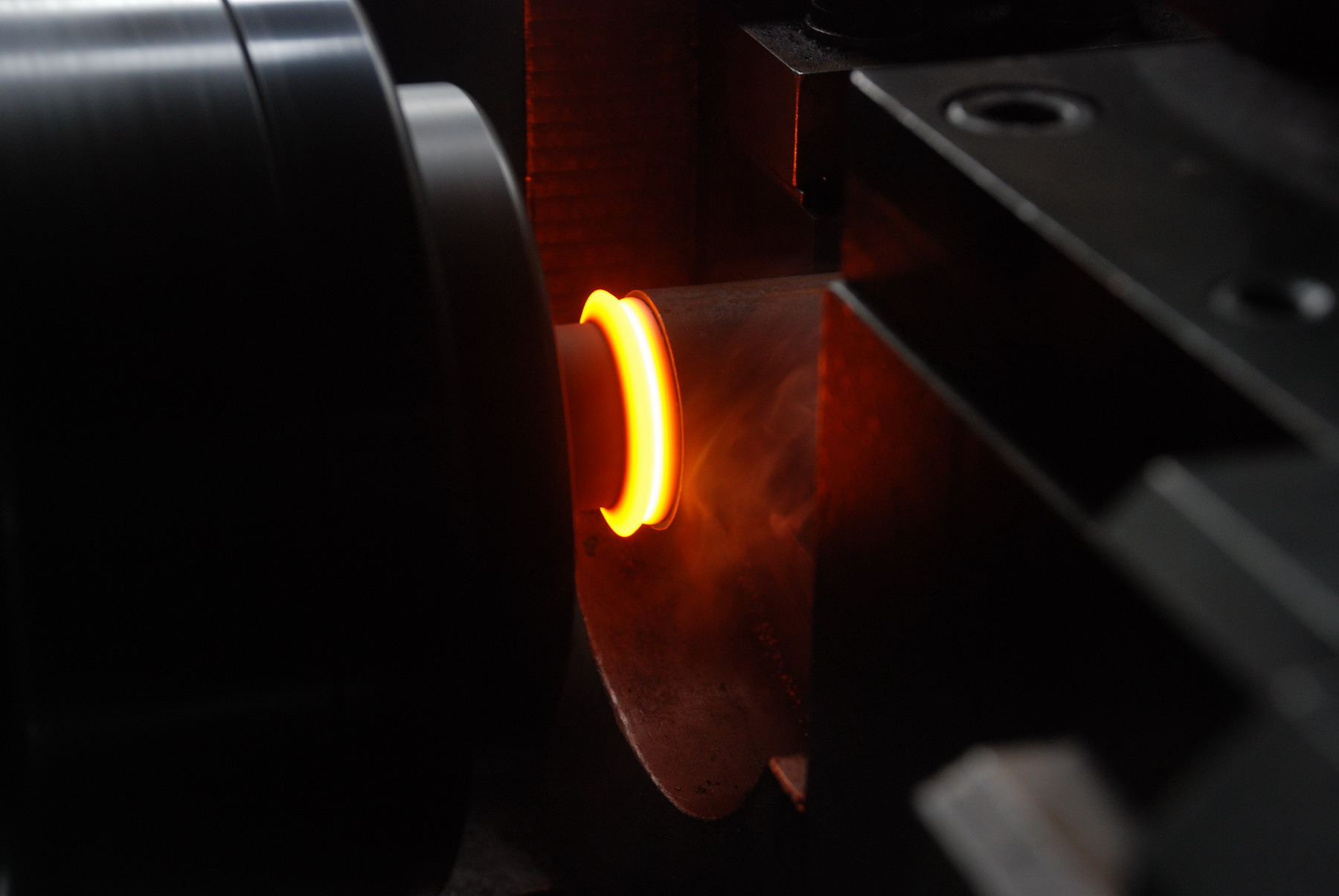

The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the amplitude and duration of the current.Th e amount of energy is chosen to match the sheet’s material properties, its thickness, and type of electrodes.

Applying too little energy won’t melt the metal or will make a poor weld. Applying too much energy will melt too much metal, eject molten material, and make a hole rather than a weld. Another attractive feature of spot welding is the energy delivered to the spot can be controlled to produce reliable welds.

Typical spot welding machines make use of two copper alloy electrodes that are positioned over the area where the bond is to be made. The two sheets of metal that are welded are clamped by the two electrodes while a large electric current is run through them. The technique is also known as resistance spot welding, because the amount of heat delivered on the spot is directly related to the resistance between the electrodes, the amplitude of the current and the duration of the applied electric current.

Spot welding is typically used when welding particular types of sheet metal. Thicker stock is more difficult to spot weld because the heat flows into the surrounding metal more easily. Spot welding can be easily identified on many sheet metal goods, such as metal buckets. Aluminum alloys can be spot welded, but their much higher thermal conductivity and electrical conductivity requires higher welding currents. This requires larger, more powerful, and more expensive welding transformers.

Perhaps the most common application of spot welding is in the automobile manufacturing industry, where it is used almost universally to weld the sheet metal to form a car. Spot welders can also be completely automated, and many of the industrial robots found on assembly lines are spot welders (the other major use for robots being painting). Spot welding is also used is in the orthodontist’s clinic, where small scale spot welding equipment is used when resizing metal “molar bands” used in orthodontics.

As a consequence, different metals with various thicknesses require different current amplitudes, types of electrodes and time intervals. For example, if the machine is not properly adjusted it could end up delivering too little or too much energy to the sheets being bonded. In the first case, the amount of energy would simply be insufficient to melt the metals and bond them, whereas if too much energy is inputted the sheets would melt excessively, creating a whole in them rather than a weld.

The energy delivered during the bonding of two sheets must be available instantaneously. In the case of high power demands, the power supply is usually equipped with an energy storage unit, otherwise this constructive element is completely useless.

A resistance-welding process in which coalescence is produced by the flow of electric current through the resistance of metals held together under pressure. Usually the upper electrode moves and applies the clamping force. Pressure must be maintained at all times during the heating cycle to prevent flashing at the electrode faces. Electrodes are water-cooled and are made of copper alloys because pure copper is soft and deforms under pressure. The electric current flows through at least seven resistances connected in series for any one weld (see illustration). After the metals have been fused together, the electrodes usually remain in place sufficiently long to cool the weld.

The electric current required for such applications is produced with the help of a step down transformer (with the electrodes forming the secondary circuit of the device), which lowers the voltage and increases the current (the voltage between the two electrodes rarely exceeds 1.5 volts, except for when there is no galvanic connection between the two, when the voltage increases to 5-10 volts, while the electric current can reach values up to 100,000 amps).

Another application is spot welding straps to nickel-cadmium or nickel-metal-hydride cells in order to make batteries. The cells are joined by spot welding thin nickel straps to the battery terminals. Spot welding can keep the battery from getting too hot, as might happen if conventional soldering were done. Good design practice must always allow for adequate accessibility. Connecting surfaces should be free of contaminants, such as scale, oil, and dirt, for quality welds. Metal thickness is generally not a factor in determining good welds.

Spot welding involves three stages; the first of which involves the electrodes being brought to the surface of the metal and applying a slight amount of pressure. The current from the electrodes is then applied briefly after which the current is removed but the electrodes remain in place in order for the material to cool. Weld times range from 0.01 sec to 0.63 sec depending on the thickness of the metal, the electrode force and the diameter of the electrodes themselves.

The equipment used in the spot welding process consists of tool holders and electrodes. The tool holders function as a mechanism to hold the electrodes firmly in place and also support optional water hoses which cool the electrodes during welding. Tool holding methods include a paddle-type, light duty, universal, and regular offset. The electrodes generally are made of a low resistance alloy, usually copper, and are designed in many different shapes and sizes depending on the application needed.

The two materials being welded together are known as the workpieces and must conduct electricity. The width of the workpieces is limited by the throat length of the welding apparatus and ranges typically from 5 to 50 inches. Workpiece thickness can range from 0.008in. to 1.25in. After the current is removed from the workpiece, it is cooled via the coolant holes in the center of the electrodes. Both water and a brine solution may be used as coolants in spot welding mechanisms.

You might also like

| Welding What is Welding ? Welding is a fabrication... | What is Plastic Welding ? Welding Plastic Definition Plastic welding... | How does Friction Welding Work ? What is Friction Welding ? Friction welding... | Welding Procedure What Are Welding Procedures ? A Welding... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope