Aluminum Oxide Overview

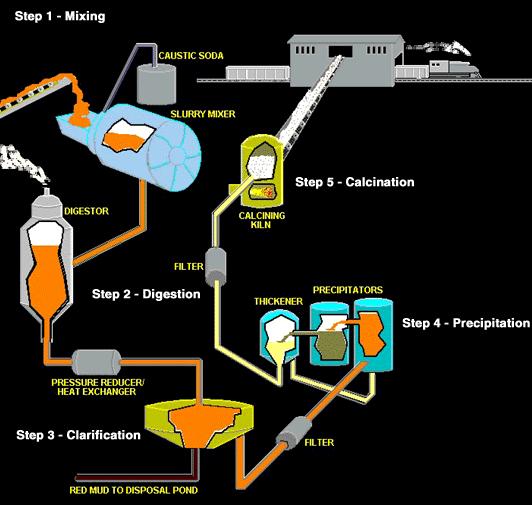

Alumina is a white granular material, a little finer than table salt, and is properly called aluminum oxide. The Bayer refining process used by alumina refineries worldwide involves four steps - digestion, clarification, precipitation and calcination. The aluminum oxide is dissolved by the caustic soda, then precipitated out of this solution, washed, and heated to drive off water.

Alumina Balls

Alumina Balls

What’s left is the white powder called alumina, which is transformed into aluminum metal in the smelting process. Aluminum originates as an oxide called alumina. Because aluminum itself does not occur in nature as a metal, the processing of aluminum took a giant leap forward with the advent of electricity. Deposits of bauxite ore are mined and refined into alumina—one of the feedstocks for aluminum metal. Then alumina and electricity are combined in a cell with molten electrolyte called cryolite. Direct-current electricity is passed from a consumable carbon anode into the cryolite, splitting the aluminum oxide into molten aluminum metal and carbon-dioxide.

You might also like

| The Bayer and Hall-Heroult Process What is The Bayer and Hall-Heroult Process... | How Aluminum is Produced ? Aluminum Production ? Aluminum manufacture... | Application of Titanium Dioxide What is Titanium Dioxide ? Titanium dioxide,... | Aluminum Welding - Beginner Guide to Weld Aluminum How to weld Aluminum ? Aluminum is the most... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope