How to weld Aluminum ?

Aluminum is the most difficult alloy to weld. Aluminum oxide should be cleaned from the surface prior to welding. Aluminum comes in heat treatable and nonheat treatable alloys. Heat treatable aluminum alloys get their strength from a process called ageing. Significant decrease in tensile strength can occurs when welding aluminum due to over aging. Aluminum is an active metal and it reacts with oxygen in the air to produce a thin hard film of aluminum oxide on the surface.

Aluminum Welding

Aluminum Welding

The melting point of aluminum oxide is approximately 1926 degress, which is almost three times the melting point of pure aluminum, 660 degrees. In addition, this aluminum oxide film, particularly as it becomes thicker, will absorb moisture from the air. Moisture is a source of hydrogen which is the cause of porosity in aluminum welds. Hydrogen may also come from oil, paint, and dirt in the weld area. It also comes from the oxide and foreign materials on the electrode or filler wire, as well as from the base metal.

Aluminum good welded

Hydrogen will enter the weld pool and is soluble in molten aluminum. As the aluminum solidifies it will retain much less hydrogen and the hydrogen is rejected during solidification. With a rapid cooling rate free hydrogen is retained within the weld and will cause porosity. Porosity will decrease weld strength and ductility depending on the amount. The aluminum oxide film must be removed prior to welding.

What do you equipment do you need ?

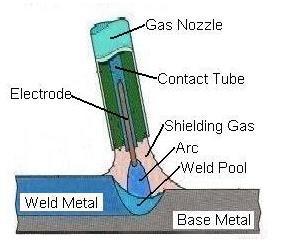

- A TIG (GTAW) welder. Most sources say a TIG (Tungsten Inert Gas) welder, also called a GTAW (Gas Tungsten Arc Welder), is the best method of welding aluminum. I’ve heard aluminum can also be welded with a MIG welder or a stick welder or even a with a gas torch. Since I’ve only used the TIG for aluminum, that’s what I’ll be writing about. TIG welders are fairly expensive and it’s hard to justify buying even the lowest quality units unless you are making money with your welding.

- Good welding gloves. I have crappy welding gloves and the painful blisters to prove it.

- A good welding helmet. I hear the gold tinted auto darkening helmets are the best.

- Argon gas. Mixes will not work for aluminum with the exception of an Argon / Helium mix. Don’t take the tank from you MIG welder to use on your TIG welder – it won’t work at all. You will just make a bunch of burnt metal and soot.

- Aluminum welding rod. I got the 4043, which seems to be the most recommended.

- A dedicated stainless steel brush that you only use for aluminum. Write “aluminum” on it so it doesn’t get used for anything else.

- A custom metal workbench would be nice. I don’t have one. Stopping your weld to put out a fire is a pain in the ass. This happens to me all the time.

- A squirt bottle with water. This is not for cooling the work, it’s for putting out small fires that aren’t big enough to use a fire extinguisher on. Cooling aluminum rapidly may cause it to crack in or near the weld.

- A fire extinguisher might not be a bad idea if you don’t want to get fired for burning down the shop.

- This next one is VERY important: a heavy long sleeve cotton work shirt. TIG welding produces more UV radiation than any other welding process. The first time I used the TIG I was wearing a tee shirt.

- Clamps or Vise Grips or whatever your going to use to hold your work in place and some blocks or bars of aluminum or copper to use as heat sinks.

Aluminum is the most difficult alloy to weld

Tips for Welding Aluminum

- Clean the aluminum. This is the most important tip I have. I read this in several places before I began to practice welding, but it didn’t seem so sink in and I wasted a lot of metal by trying to weld two pieces of dirty aluminum together. ALUMINUM THAT LOOKS BRAND NEW AND CLEAN IS ACTUALLY DIRTY. IT’S NOT LIKE STEEL. Here’s what’s happening: Aluminum quickly forms an more or less invisible coating of aluminum oxide. Aluminum oxide melts at three times the temperature of aluminum. When you try to weld uncleaned aluminum, the aluminum under the aluminum oxide coating will melt but the aluminum oxide coating will stay solid and act as a membrane, much like a water balloon. When you finally succeed in penetrating the coating, the very runny aluminum inside will flow out all at once, much like a bursting water balloon.

- Clamp your work to a heatsink made of copper or aluminum whenever possible. Aluminum transmits heat very well. Once the area you trying to weld gets hot enough to melt, the rest of the work is likely to be so hot that it’s shrinking and warping. Using a heat sink under the area being welded will absorb some of the heat and help keep the work from warping

- Preheat before welding. This makes it a LOT easier to weld aluminum. This is not a subject that is without controversy. The issue is that some aluminum is heat treated, and by heating and cooling heat treated aluminum it will get softer. I’ve read opinions ranging from “heat treated aluminum should never be preheated” and “preheating is a crutch for inexperienced welders”, to the opposite extreme, “aluminum should always be preheated to prevent cracking”. Recommended preheating temperatures range from 275 deg. F, to 500 deg. F. I suspect that many of these opinions are correct in their own contexts.

- If the tungsten gets contaminated, stop welding and fix it. When the tungsten gets touches the weld pool or the filler, the arc becomes unstable and the weld quality goes way down. This happens to me a lot, unfortunately. The best method for fixing this is to remove the tungsten, lay it on a flat surface with the contaminated part hanging over the edge, hit the contaminated part of the tungsten (it will snap right off), reinstall the tungsten, change the polarity to DCEP (direct current electrode positive), strike an arc on some scrap metal to re-ball the tungsten, switch back to AC high, and you’re ready to weld again. By the way, KEEP YOUR GLOVES ON WHILE YOU DO THIS! Otherwise you gonna have a nasty burn. This only takes about 30 seconds once you’ve done it a few times.

- Fit the parts together as tightly as possible leaving no gaps. When using a MIG welder, I’ve found it fairly easy to fill gaps between the two pieces of steel being welded. However, I’ve found it very hard to do this while welding aluminum with the TIG. The heat from the TIG is very localized. When there is a gap, and heat is applied to the metal on one side, the metal pools on that side, but metal on the other side stays solid. You can alternate from side to side to get both sides to pool, but when I do this, I usually end up with a wider gap than when I started. The only way I’ve found to fill a gap is to “slop” a glob of filler across the gap, then work on the filler until it melts into both sides, then build off of the filler. This is hard to do. You can save a lot of time by using a file or die grinder and making the part fit together better before you start welding. The tighter the pieces are pressed together and the fewer the gaps, the easier the welding is.

- A few “rules of thumb” for base settings. Use one amp per .001″ of material thickness. Set the amperage a higher than the maximum you expect to use and use the foot pedal to back it down. Use pure tungsten for aluminum if you have a cheaper (non-square wave) welder like me. Use a 2% ceriated tungsten ground to a point if you have a more expensive (square wave) welder. Use a 1/16″ pure tungsten for 30 to 80 amps. Use a 3/32″ pure tungsten for 60 to 130 amps. Use a 1/8″ pure tungsten for 100 to 180 amps. Use 15 to 20 CFH Argon flow. Use a filler rod size equal to the tungsten size. Adjust the tungsten to project from the hood a distance roughly equal to the diameter of the tungsten. The arc length should be roughly equal to the diameter of the tungsten.

The first 3 tips were my major breakthroughs while learning to weld. They were the things I wished somebody had told me before I began my frustrating experimentation. There are, of course, many other things to know about welding aluminum, but there are many more complete articles available on the Internet. Follow the links below for some of my favorites.

You might also like

| What is TIG WELDING ? Gas tungsten arc welding (GTAW), also known... | MIG Welding MIG Welding - Overview MIG welding is an... | Welding Machine - Equipment and Procedure for GTA Welding Welding Machine and Equipment for GTA Welding Gas... | Aluminum Foil Aluminum foil is made from an aluminum... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope