Friction Stir Welding - How Does It Works ?

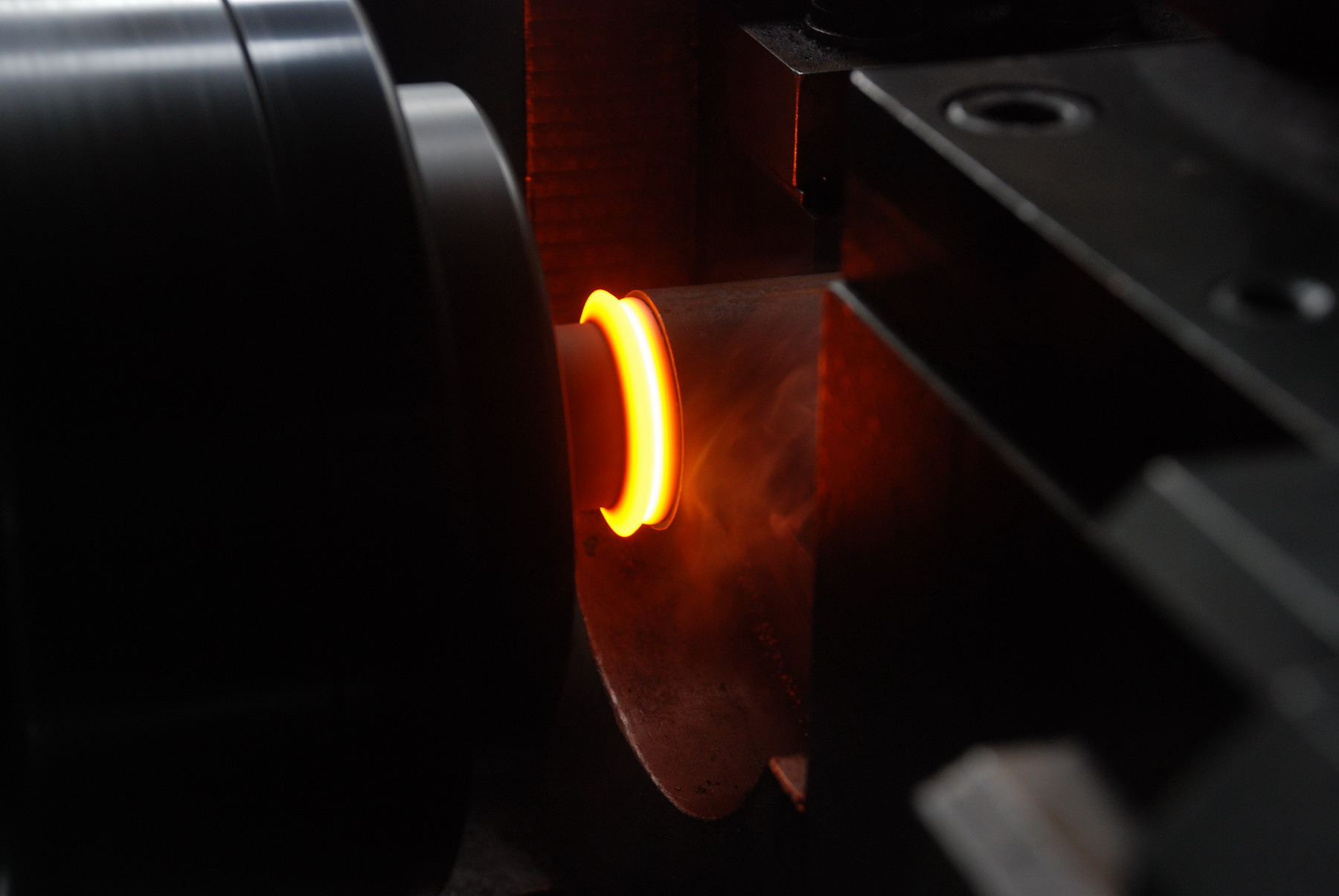

Friction stir welding, a process invented at TWI, Cambridge, involves the joining of metals without fusion or filler materials. The welds are created by the combined action of frictional heating and mechanical deformation due to a rotating tool. The probe penetrates the workpiece whereas the shoulder rubs with the top surface.

The heat is generated primarily by friction between a rotating-translating tool, the shoulder of which rubs against the workpiece. There is a volumetric contribution to heat generation from the adiabatic heating due to deformation near the pin. The microstructure of a friction-stir welddepends in detail on the tool design, the rotation and translation speeds, the applied pressure and the characteristics of the material being joined. The heat-affected zone (HAZ) is as in conventional welds.

You might also like

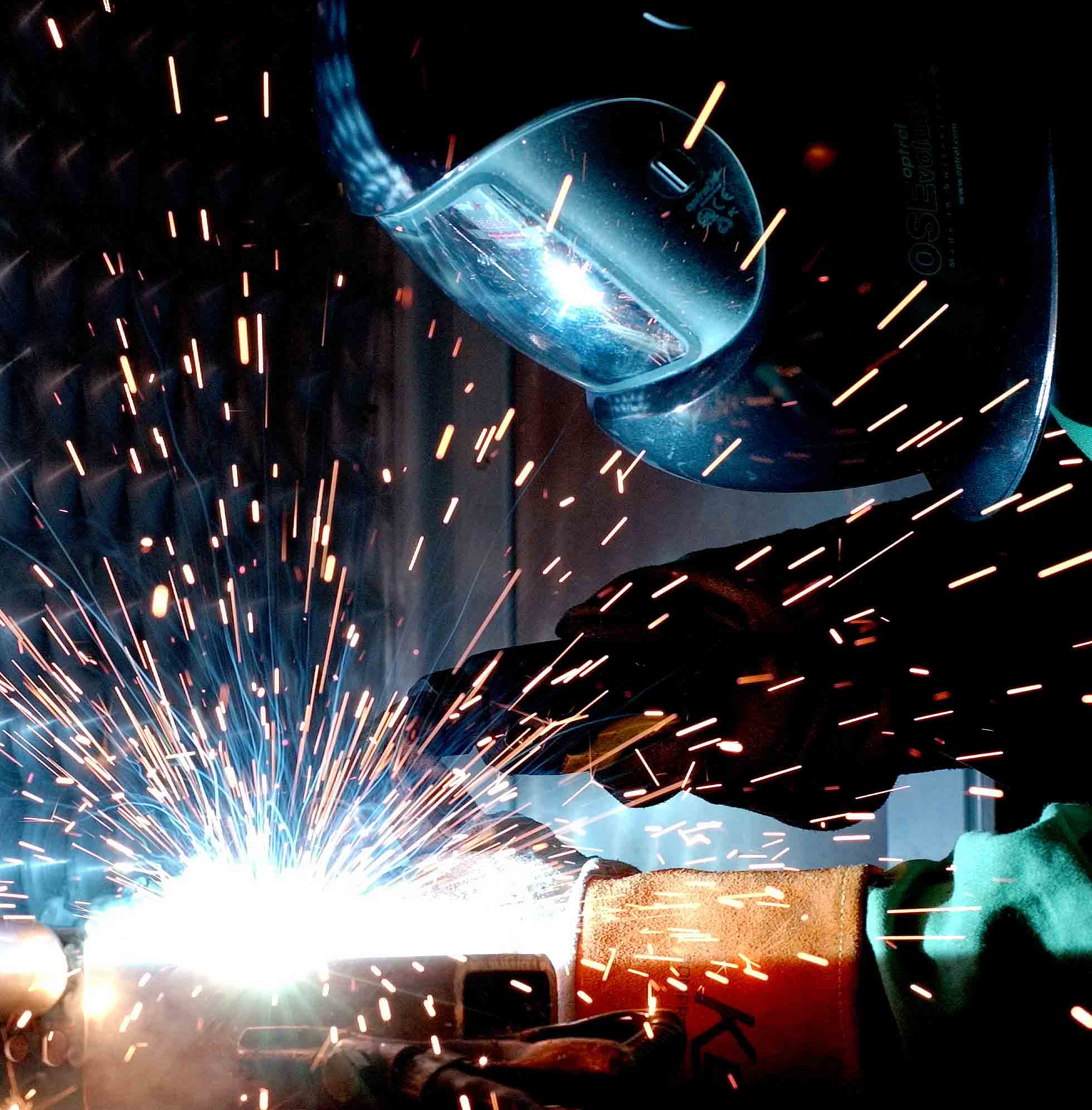

| How does Friction Welding Work ? What is Friction Welding ? Friction welding... | Welding Pictures Welding Pictures Welding is a fabrication or sculptural process that... | What is Plastic Welding ? Welding Plastic Definition Plastic welding... | Welding What is Welding ? Welding is a fabrication... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope