Welding Plastic Definition

Plastic welding or heat sealing is the process of welding plastic workpieces together. It is a very common process for joining plastics.

Plastic Welding Tools

Plastic Welding Tools

Plastic welding is the process of melting two pieces of plastic and joining them together. There are a variety of ways to weld plastic. These techniques often use gas and other dangerous equipment, and should only be done by a professional.

A number of techniques are used for welding plastics :

Hot gas welding

A welding gun must be used to weld with hot gas. The hot gas travels through the gun, is heated by electric elements within the gun, and streamed over the area to be welded. Once the plastic begins to melt, the pieces are joined together. Hot gas welding, also known as hot air welding, is a plastic welding technique which is analogous to gas welding metals, though the specific techniques are different.

Hot Gas Plastic Welding

A specially designed heat gun, called a hot air welder, produces a jet of hot air that softens both the parts to be joined and a plastic filler rod, all of which must be of the same or a very similar plastic. Welding PVC to acrylic is an exception to this rule. Hot air/gas welding is a common fabrication technique for manufacturing smaller items such as chemical tanks, water tanks, heat exchangers, and plumbing fittings. In the case of webs and films a filler rod may not be used. Two sheets of plastic are heated via a hot gas (or a heating element) and then rolled together. This is a quick welding process and can be performed continuously.

High Frequency

The use of electromagnetic waves to soften plastic for joining is called high frequency welding. Radio frequency is often used when a continuous and localized technique is required. Certain plastics with chemical dipoles, such as PVC, polyamides (PA) and acetates can be heated with high frequency electromagnetic waves. High frequency welding uses this property to soften the plastics for joining. The heating can be localized, and the process can be continuous. Also known as Dielectric Sealing, R.F. (Radio Frequency) Heat Sealing.

High Frequency Plastic Welding Machine

In a ferromagnetic work piece, plastics can be induction-welded by formulating them with metallic or ferromagnetic compounds, called susceptors. These susceptors absorb electromagnetic energy from an induction coil, become hot, and lose their heat energy to the surrounding material by thermal conduction.

Radio frequency welding is a very mature technology that has been around since the 1940s. Two pieces of material are placed on a table press that applies pressure to both surface areas. Dies are used to direct the welding process.

When the press comes together, high frequency waves (usually 27.12 MHz) are passed through the small area between the die and the table where the weld takes place.

This high frequency (radio frequency) field causes the molecules in certain materials to move and get hot, and the combination of this heat under pressure causes the weld to take the shape of the die. RF welding is fast.

This type of welding is used to connect polymer films used in a variety of industries where a strong consistent leak-proof seal is required. In the fabrics industry, RF is most often used to weld PVC and polyurethane (PU) coated fabrics. This is a very consistent method of welding. The most common materials used in RF welding are PVC and polyurethane. It is also possible to weld other polymers such as nylon, PET, EVA and some ABS plastics.

Solvent welding

In solvent welding, a solvent is applied which can temporarily dissolve the polymer at room temperature. When this occurs, the polymer chains are free to move in the liquid and can mingle with other similarly dissolved chains in the other component. Given sufficient time, the solvent will permeate through the polymer and out into the environment, so that the chains lose their mobility. This leaves a solid mass of entangled polymer chains which constitutes a solvent weld. This technique is commonly used for connecting PVC and ABS pipe, as in household plumbing. The “gluing” together of plastic (polycarbonate, polystyrene or ABS) models is also a solvent welding process.

Ultrasonic

Ultrasonic also uses high frequency with low amplitude vibrations. According to Mark Williams, Quality Control Manager at Wilco Molding, the friction created by the vibrations heat and melt the plasti so that the two pieces can be joined together. In ultrasonic welding, high frequency (15 kHz to 40 kHz) low amplitude vibration is used to create heat by way of friction between the materials to be joined. The interface of the two parts is specially designed to concentrate the energy for the maximum weld strength. Ultrasonic can be used on almost all plastic material. It is the fastest heat sealing technology available.

Freehand

Freehand welding is a long and tedious process, but can be used to weld almost any project. The stream of hot air shoots down the molding rod and on the section to be welded. When the rod becomes soft, it is pushed into the area to be joined. With freehand welding, the jet of hot air (or inert gas) from the welder is played on the weld area and the tip of the weld rod at the same time. As the rod softens, it is pushed into the joint and fuses to the parts. This process is slower than most others, but it can be used in almost any situation.

Friction welding

In friction welding, the two parts to be assembled are rubbed together at a lower frequency (typically 100–300 Hz) and higher amplitude (typically 1 to 2 mm (0.039 to 0.079 in)) than ultrasonic welding. The friction caused by the motion combined with the clamping pressure between the two parts creates the heat which begins to melt the contact areas between the two parts.

At this point, the plasticized materials begin to form layers that intertwine with one another, which therefore results in a strong weld. At the completion of the vibration motion, the parts remain held together until the weld joint cools and the melted plastic re-solidifies. The friction movement can be linear or orbital, and the joint design of the two parts has to allow this movement.

Hot Plate

Hot plate welding is often used for large pieces of plastic. A plate is placed between the two pieces until the area melts. The plastic is then joined together. Related to contact welding, this technique is used to weld larger parts, or parts that have a complex weld joint geometry. The two parts to be welded are placed in the tooling attached to the two opposing platens of a press.

A hot plate, with a shape that matches the weld joint geometry of the parts to be welded, is moved in position between the two parts. The two opposing platens move the parts into contact with the hot plate until the heat softens the interfaces to the melting point of the plastic. When this condition is achieved the hot plate is removed, and the parts are pressed together and held until the weld joint cools and re-solidifies to create a permanent bond.

Laser welding

This technique requires one part to be transmissive to a laser beam and either the other part absorptive or a coating at the interface to be absorptive to the beam. The two parts are put under pressure while the laser beam moves along the joining line. The beam passes through the first part and is absorbed by the other one or the coating to generate enough heat to soften the interface creating a permanent weld.

Semiconductor diode lasers are typically used in plastic welding. Wavelengths in the range of 808 nm to 980 nm can be used to join various plastic material combinations. Power levels from less than 1W to 100W are needed depending on the materials, thickness and desired process speed.

Extrusion welding

Extrusion welding allows the application of bigger welds in a single weld pass. It is the preferred technique for joining material over 6 mm thick. Welding rod is drawn into a miniature hand held plastic extruder, plasticized, and forced out of the extruder against the parts being joined, which are softened with a jet of hot air to allow bonding to take place.

You might also like

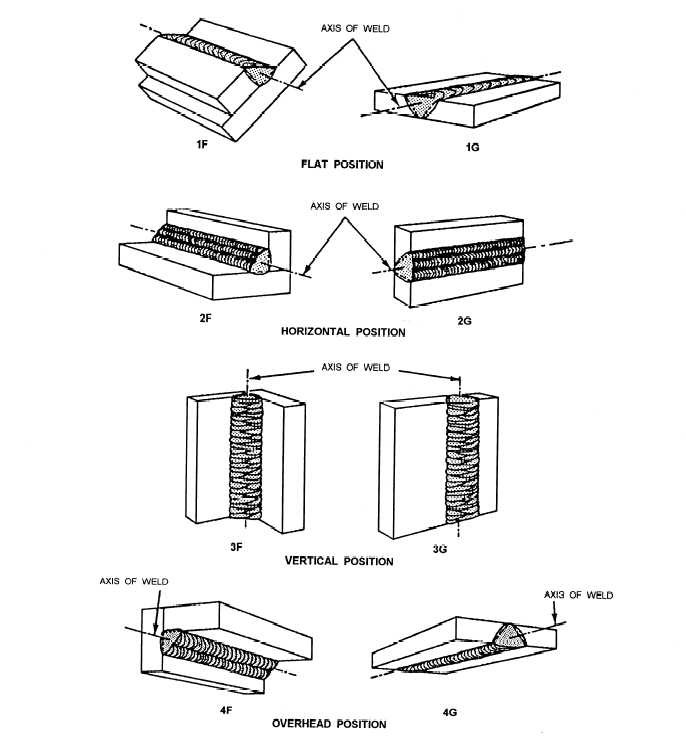

| Welding Procedure What Are Welding Procedures ? A Welding... | Steel Pipe - Definition and Overview What is Steel Pipe ? Pipe is a hollow tube... | Welding Positions What`s Kind of Welding Positions ? Welding... | What is TIG WELDING ? TIG Welding - an Overview Gas tungsten arc... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope