Precipitation Hardening Overview

Precipitation hardening also called age hardening, is a heat treatment technique used to increase the yield strength of malleable materials, including most structural alloys ofaluminium, magnesium, nickel, titanium, and some stainless steels. Precipitation hardening relies on changes in solid solubility with temperature to produce fine particles of an impurity phase, which impede the movement of dislocations, or defects in a crystal’s lattice. Unlike ordinary tempering, alloys must be kept at elevated temperature for hours to allow precipitation to take place. This time delay is called aging.

Note that two different heat treatments involving precipitates can alter the strength of a material: solution heat treating and precipitation heat treating. Solid solution strengtheninginvolves formation of a single-phase solid solution via quenching. Precipitation heat treating involves the addition of impurity particles to increase a material’s strength. Precipitation hardening via precipitation heat treatment is the main topic of discussion in this article.

Precipitation hardening, or age hardening, provides one of the most widely used mechanisms for the strengthening of metal alloys. The fundamental under¬standing and basis for this technique was established in early work at the U. S. Bureau of Standards on an alloy known as Duralumin. Duralumin is an aluminum alloy containing copper and magnesium with small amounts of iron and silicon. The authors proceeded to develop an insightful explanation for the hardening behavior of Duralumin which rapidly became the model on which innumerable modern high-strength alloys have been developed.

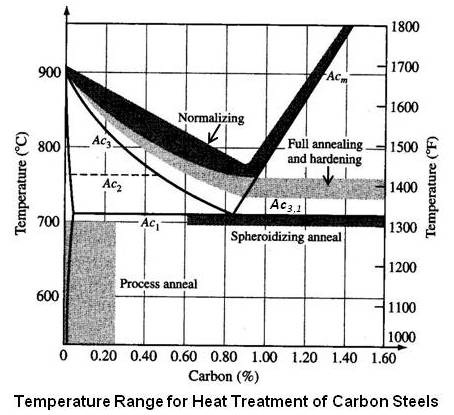

The precipitation-hardening process involves three basic steps :

1) Solution Treatment, or Solutionizing, is the first step in the precipitation-hardening process where the alloy is heated above the solvus temperature and soaked there until a homogeneous solid solution (?) is produced. The ? precipitates are dissolved in this step and any segregation present in the original alloy is reduced.

2) Quenching is the second step where the solid ? is rapidly cooled forming a supersaturated solid solution of ?SS which contains excess copper and is not an equilibrium structure. The atoms do not have time to diffuse to potential nucleation sites and thus ? precipitates do not form.

3) Aging is the third step where the supersaturated ?, ?SS, is heated below the solvus temperature to produce a finely dispersed precipitate. Atoms diffuse only short distances at this aging temperature. Because the supersaturated ? is not stable, the extra copper atoms diffuse to numerous nucleation sites and precipitates grow. The formation of a finely dispersed precipitate in the alloy is the objective of the precipitation-hardening process. The fine precipitates in the alloy impede dislocation movement by forcing the dislocations to either cut through the precipitated particles or go around them. By restricting dislocation movement during deformation, the alloy is strengthened. Age Hardening – Precipitation. The strongest aluminum alloys (2xxx, 6xxx and 7xxx) are produced by age hardening. A fine dispersion of precipitates can be formed by appropriate heat treatment.

The aluminum rich end of the Al-Cu phase diagram showing the three steps in the age-hardening heat treatment and the microstructures that are produced.

The primary species of precipitation strengthening are second phase particles. These particles impede the movement of dislocations throughout the lattice. You can determine whether or not second phase particles will precipitate into solution from the solidus line on the phase diagram for the particles. Physically, this strengthening effect can be attributed both to size and modulus effects, and to interfacial or surface energy.

Example of age hardening 2XXX series aluminium alloy system. Source: Gibson, J. (n.d.) Equilibrium diagrams and common metal alloy systems. Sydney: Clarendon.

The presence of second phase particles often causes lattice distortions. These lattice distortions result when the precipitate particles differ in size and crystallographic structure from the host atoms. Smaller precipitate particles in a host lattice leads to a tensile stress, whereas larger precipitate particles leads to a compressive stress. Dislocation defects also create a stress field. Above the dislocation there is a compressive stress and below there is a tensile stress. Consequently, there is a negative interaction energy between a dislocation and a precipitate that each respectively cause a compressive and a tensile stress or vice versa. In other words, the dislocation will be attracted to the precipitate. In addition, there is a positive interaction energy between a dislocation and a precipitate that have the same type of stress field. This means that the dislocation will be repulsed by the precipitate.

You might also like

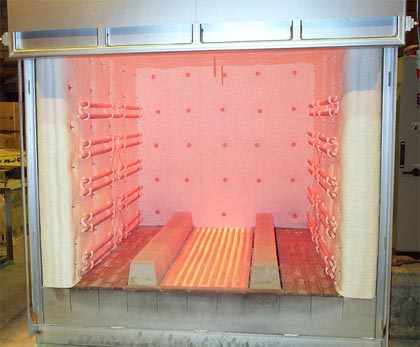

| Heat Treatment Furnaces Heat Treatment Furnaces of Steel Heat treating... | Optimal Combination of STRENGTH and TOUGHNESS Optimal Combination of STRENGTH and TOUGHNESS Preceding... | Aluminum “Hardening” - How it works? Heat Treatment of Aluminum The term “heat... | Do you know Heat Treatment process ? Heat Treatment Heat Treatment is the controlled... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope