Mild Steel - Properties and Uses

What is Mild Steel?

Mild steel is a type of steel alloy, that contains a high amount of carbon as a major constituent. An alloy is a mixture of metals and non-metals, designed to have specific properties. Alloys make it possible to compensate for the shortcomings of a pure metal by adding other elements. To get what mild steel is, one must know what are the alloys that are combined to make steel. So, let us see what we mean by steel, which will help us in understanding what mild steel is and also in understanding the properties of mild steel.

Mild Steel Beam

Mild Steel Beam

The term ‘mild steel’ is also applied commercially to carbon steels not covered by standard specifications. Carbon content of this steel may vary from quite low levels up to approximately 0.3%. Generally, commercial ‘mild steer’ can be expected to be readily weldable and have reasonable cold bending properties but to specify ‘mild steel’ is technically inappropriate and should not be used as a term in engineering.

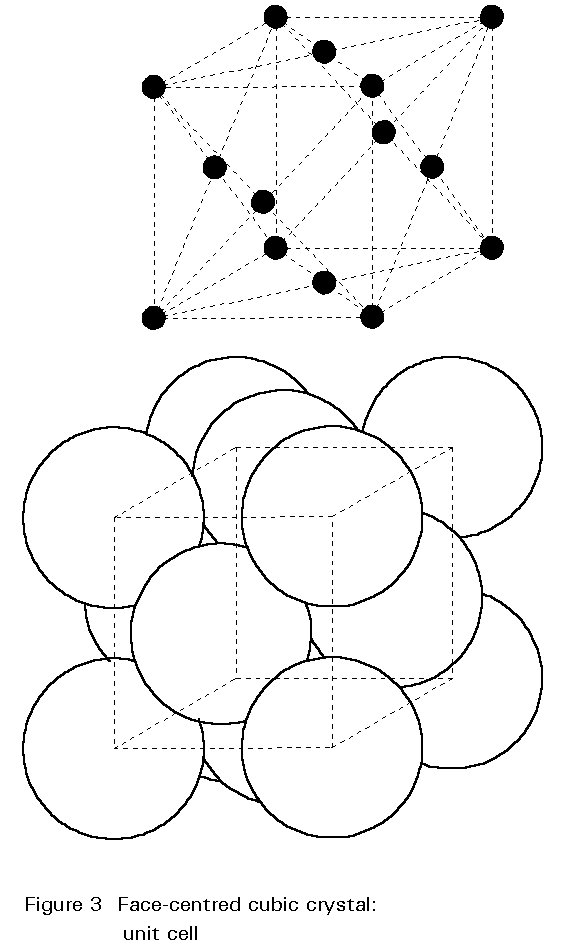

Steel is any alloy of iron, consisting of 0.2% to 2.1% of carbon, as a hardening agent. Besides carbon, there are many metal elements that are a part of steel alloys. The elements other than iron and carbon, used in steel are chromium, manganese, tungsten and vanadium. All these elements along with carbon, act as hardening agents. That is, they prevent dislocations from occurring inside the iron crystals and prevent the lattice layers from sliding past each other. This is what makes steel harder than iron.

Sheet Mild Steel

The difference between mild steel and hard steel can be divided by whether they exist yield point. As hard steel has not obvious yield point, so plasticity is worse than mild steel. Mild steel has very obvious yield point and large enlongation rate is large. Hard steel has high intensity but its plasticity is not very good. The plasticity of a kind of steel directly affect the structure fitting, so reinforcing steel should choose mild steel.

Varying the amounts of these hardening agents, creates different grades of steel. The ductility, hardness and mild steel tensile strength is a function of the amount of carbon and other hardening agents, present in the alloy. The amount of carbon is a deciding factor, which decides hardness of the steel alloy. A steel alloy with a high carbon content is mild steel, which is in fact, much more harder and stronger than iron. Though, increased carbon content increases the hardness of the steel alloy, it causes a decrease in its ductility.

Mild steel is the most common form of steel because its price is relatively low while it provides material properties that are acceptable for many applications. Low carbon steel contains approximately 0.05–0.15% carbon and mild steel contains 0.16–0.29%[1] carbon therefore, it is neither brittle nor ductile. Mild steel has a relatively low tensile strength, but it is cheap and malleable, surface hardness can be increased through carburizing.

It is often used when large quantities of steel are needed, for example as structural steel. The density of mild steel is approximately 7.85 g/cm3 (7850 kg/m3 or 0.284 lb/in3) and the Young’s modulus is 210,000 MPa (30,000,000 psi). Low carbon steels suffer from yield-point runout where the material has two yield points. The first yield point (or upper yield point) is higher than the second and the yield drops dramatically after the upper yield point. If a low carbon steel is only stressed to some point between the upper and lower yield point then the surface may develop Lüder bands.

Mild steel can also be described as steel which is not stainless steel. Mild steel differs from stainless steel in its chromium content. Stainless steel contains a lot more chromium than ordinary carbon or mild steel. Here is a compilation of mild steel properties and its uses in various fields of technology :

- Let us see, what makes the mild steel composition. Other than maximum limit of 2 % carbon in the manufacture of carbon steel, the proportions of manganese (1.65%), copper (0.6%) and silicon (0.6%) are fixed, while the proportions of cobalt, chromium, niobium, molybdenum, titanium, nickel, tungsten, vanadium and zirconium are not.

- A high amount of carbon makes mild steel different from other types of steel. Carbon makes mild steel stronger and stiffer than other type of steel. However, the hardness comes at the price of a decrease in the ductility of this alloy. Carbon atoms get affixed in the interstitial sites of the iron lattice and make it stronger.

- What is known as mildest grade of carbon steel or ‘mild steel’ is typically carbon steel, with a comparatively mild amount of carbon (0.16% to 0.19%). It has ferromagnetic properties, which make it ideal for manufacture of electrical devices and motors.

- The calculated average industry grade mild steel density is 7.85 gm/cm3. Its Young’s modulus, which is a measure of its stiffness is around 210,000 Mpa.

- Mild steel is the cheapest and most versatile form of steel and serves every application which requires a bulk amount of steel.

- The high amount of carbon, also makes mild steel vulnerable to rust. Naturally, people prefer stainless steel over mild steel, when they want a rust free technology. Mild steel is also used in construction as structural steel. It is also widely used in the car manufacturing industry.

So, these are some of the mild steel properties and its uses. Uses of mild steel extend over almost all forms of industrial applications and industrial manufacturing.

Alloy Suppliers

Alloy Suppliers  Aluminum

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope