Metal Spraying

Metal spraying is spraying hot metal on to a surface to create a coating. Thermal spraying techniques are coating processes in which melted (or heated) materials are sprayed onto a surface. The “feedstock” (coating precursor) is heated by electrical (plasma or arc) or chemical means (combustion flame).

Metal spraying

Metal spraying

Thermal spraying can provide thick coatings (approx. thickness range is 20 micrometers to several mm, depending on the process and feedstock), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition. Coating materials available for thermal spraying include metals, alloys, ceramics, plastics and composites.

They are fed in powder or wire form, heated to a molten or semimolten state and accelerated towards substrates in the form of micrometer-size particles.

The Combustion Wire Thermal Spray Process

The Combustion Wire Thermal Spray Process

Combustion or electrical arc discharge is usually used as the source of energy for thermal spraying. Resulting coatings are made by the accumulation of numerous sprayed particles. The surface may not heat up significantly, allowing the coating of flammable substances.

Metal Spraying - Powder and Wire

Metal Spraying - Powder and Wire

Coating quality is usually assessed by measuring its porosity, oxide content, macro and micro-hardness, bond strength and surface roughness. Generally, the coating quality increases with increasing particle velocities.

Several variations of thermal spraying are distinguished :

- Plasma spraying

- Detonation spraying

- Wire arc spraying

- Flame spraying

- High velocity oxy-fuel coating spraying (HVOF)

- Warm spraying

- Cold spraying

In classical (developed between 1910 and 1920) but still widely used processes such as flame spraying and wire arc spraying, the particle velocities are generally low (< 150 m/s), and raw materials must be molten to be deposited. Plasma spraying, developed in the 1970s, uses a high-temperature plasma jet generated by arc discharge with typical temperatures >15000 K, which makes it possible to spray refractory materials such as oxides, molybdenum, etc.

Pre-treatment :

Surface adhesion is purely mechanical and as such, a solid key is required, free of grease or other contaminants. Therefore the careful cleaning and pre-treatment of the surface to be coated is extremely important. Surface roughening usually takes place via grit blasting with dry corundum. In addition, other media, such as chilled iron, steel grit or SiC are used for some applications.

Pretreatment Metal Spraying

Pretreatment Metal Spraying

All items are grit blasted with sharp abrasive grit to achieve a surface roughness of approximately 100-300µin. Besides the type of grit, other important factors include particle size, particle shape, blast angle, pressure and purity of the grit media.Suitable substrate materials are those that can withstand blasting procedures to roughen the surface, generally having a surface hardness of about 55 Rockwell C or lower. Special processing techniques are required to prepare substrates with a higher hardness.

Some of the available metal spray materials include:

Aluminium coatings

provide protection against corrosive atmospheric environments. Aluminium silicon coatings are used for repair and restoration of aluminium based substrates and for low temperature seal applications in compressors. The addition of silicon in the aluminium alloy provides improved machining capability over coatings of pure aluminium.

Bronze coatings

produce a dense wear resistant coating, which is especially good for mis-machined components, repairs, restoration or to provide a bearing surface on a different substrate.

Coatings of pure copper

provide good conductivity for electrical applications. Copper alloy coatings are used for machine element work, salvage, repair and restoration of copper based substrates.

Carbon and low alloy steel

appropriate for general-purpose wear applications are available. The various grades with differing carbon content effect coating hardness and wear resistance. Stainless steel alloys are also readily available. All of these products are appropriate for general restoration, salvage and build-up of worn and mis-machined components, with harder alloys providing additional wear resistance.

Lead based coatings (equivalent to white metal)

provide a self-lubricating bearing surface and exhibit good resistance to acids and other strong reagents. Ideal suitability includes adjustable bearing shoes in machine tools.

Molybdenum coatings

produce hard, lubricious surfaces that are resistant to abrasion, galling and scuffing and exhibit a very low coefficient of friction. These characteristics are the result of molybdenum oxide formation on the surface. Key applications for this material are for automotive and other transportation equipment components.

Plasma Spray Process

The Plasma Spray Process is basically the spraying of molten or heat softened material onto a surface to provide a coating. Material in the form of powder is injected into a very high temperature plasma flame, where it is rapidly heated and accelerated to a high velocity.

Schematic Diagram of the Plasma Spray Process

Schematic Diagram of the Plasma Spray Process

The hot material impacts on the substrate surface and rapidly cools forming a coating. This plasma spray process carried out correctly is called a “cold process” (relative to the substrate material being coated) as the substrate temperature can be kept low during processing avoiding damage, metallurgical changes and distortion to the substrate material.

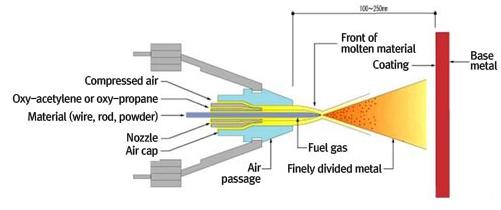

Flame Wire Spraying

In flame wire spraying, a typical gas spraying method, wires are consecutively fed into a gas flame, such as oxy-acetylene or oxy-propane, get molten and sprayed using compressed air to form coatings.

Flame Wire Spraying Diagram

Flame Wire Spraying Diagram

Characteristics :

- Using lightweight equipment, suitable for on-site construction

- Little to no thermal distortion of base metals

- Adjustable thickness range (0.1~10 micrometers)

- A wide choice of materials

- High wear resistance of coatings

All kinds of metals that can be made into wires, including zinc, aluminum, carbon steel, stainless steel, and molybdenum, can be applied to this spraying technique. Thickness range is wide, from 0.1 up to 10 micrometers.

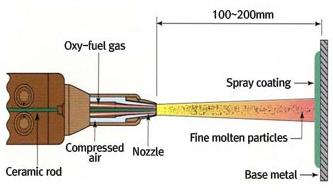

Flame Rod Spraying

Using the same principle as flame wire spraying, this method requires an oxide ceramic rod as a coating material. The ceramic rod is fed into an oxy-acetylene flame, gets heated and molten, then becomes finely divided by compressed air and solidified on a base metal, forming a coating. Since it uses ceramics, this method is suitable for corrosion-protection spraying or wear-control spraying, which improves heat resistance around hot areas.

Flame Wire Spraying

Flame Wire Spraying

Characteristics :

- Sprays completely molten particles only

- Provides excellent coupling of particles and forms highly cohesive coatings

- Three or four times faster than powder spraying

- Less affected by heat than plasma spraying

- Limited choice of coating materials (limited to oxide ceramics)

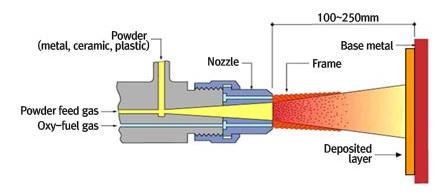

Flame Powder Spraying

In this form of spraying, a powder material is fed into a spray gun through a powder pump and gets molten and heated in a high-temperature flame, forming a coating. There are largely three powder feed methods: linking the powder pump directly to the spray gun, using a separate powder pump, and feeding into the spray gun using an inactive gas (e.g., nitrogen).

Flame Powder Spraying Diagram

Flame Powder Spraying Diagram

Characteristics :

- A wide choice of materials, including metals, alloys, plastics, and ceramics

- Long melting time in a flame provides the excellent adhesive strength of materials (90% efficiency for self-fluxing alloys)

- Very low noise level

- Uses compressed gases for the acceleration and cooling of particles

- Using a light spray gun allows manual spraying

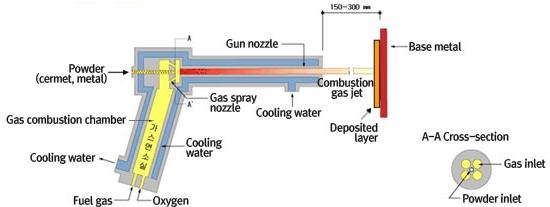

HVOF Flame Spraying

This method forms coatings by using powerful spray impact generated by the increased spray velocity. Using the same fuel gas as flame spraying, it is divided into HVOF (High Velocity Oxy-Fuel) using a mixture of fuel and oxygen and HVAF (High Velocity Air-Fuel) using a mixture of fuel and air. It works under the principle that

- Combustion occurs inside a tube

- A combustion gas is sprayed at high velocity through a nozzle

- Powder is fed into the sprayed gas and gets heated, molten, and sprayed at high velocity, finally forming a coating.

HVOF Flame Spraying Diagram

HVOF Flame Spraying Diagram

Characteristics :

- Two or four times faster spraying

- Can form delicate coatings

- Oxidation occurs less

- Requires finer powders

- Can cause clogging in the spray gun

- Generates ultrasound

- Work needs to get done inside an isolated soundproof room

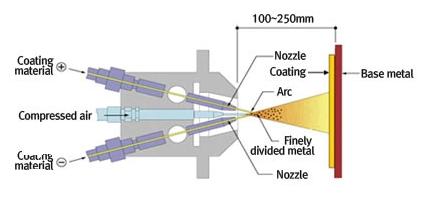

Arc Spraying

In this typical electric spraying, two metal wires generate electrical arc discharge and get molten and fed in keeping pace with the melting velocity. The melted metals then get finely divided by compressed air and consecutively molded on a base metal, forming a coating. Compared with the flame spraying methods, it shows excellent performance. Since a coating material can be thoroughly molten under high temperature, it provides outstanding adhesion to a base material. However, coating materials are limited to those electrically conductive.

Arc Spraying Diagram

Arc Spraying Diagram

Characteristics :

- Fast spraying (two to four times faster than flame spraying)

- High adhesive strength and coating strength

- Using different types of materials, can form alloy coatings

- Low operating costs

Detonation Thermal Spraying Process

Schematic Diagram of the Detonation Thermal Spray Process

Schematic Diagram of the Detonation Thermal Spray Process

The Detonation gun basically consists of a long water cooled barrel with inlet valves for gases and powder. Oxygen and fuel (acetylene most common) is fed into the barrel along with a charge of powder. A spark is used to ignite the gas mixture and the resulting detonation heats and accelerates the powder to supersonic velocity down the barrel. A pulse of nitrogen is used to purge the barrel after each detonation. This process is repeated many times a second. The high kinetic energy of the hot powder particles on impact with the substrate result in a build up of a very dense and strong coating.

Alloy Suppliers

Alloy Suppliers  Aluminum

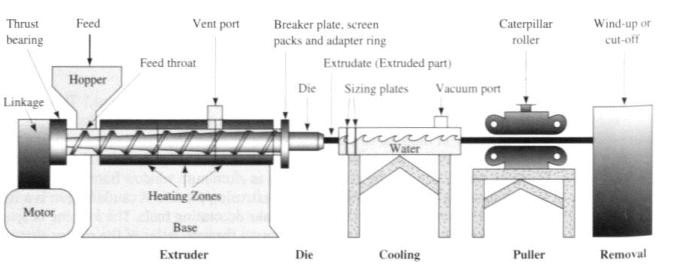

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope