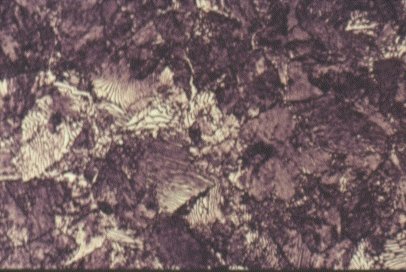

The engineering properties of steel, i.e. strength, ductility and resistance against brittle fracture, depend on its crystalline structure, grain size and other metallurgical characteristics.These microstructural properties are dependent on the chemical composition and on the temperature-deformation history of the steel. that occur during welding may also have a large influence on the engineering properties.

Diamonds Crystal Structure

Diamonds Crystal Structure

When selecting steel for welded structures, it is important to have at least a basic knowledge of metallurgy. This knowledge is required especially when large and complicated structures are being designed, such as bridges, offshore structures, and high rise buildings. Selecting materials, welding processes and welding consumables usually requires consultation of “real” metallurgists and welding specialists.

Metallurgists are engineers that study the properties of metals

Metallurgists are engineers that study the properties of metals

A basic knowledge of metallurgy is essential for communication with these specialists. Finally, a basic knowledge of metallurgy also enables civil and structural engineers to have a better understanding of the engineering properties of steel and the performance of welded structures.

You might also like

| Types of Materials Metals: Metals are elements... | Cooling Rate Cooling Rate During Austenite to Ferrite... | Austempered Ductile Iron (ADI) Austempered Ductile Iron (ADI) is... | Advanced Ceramics A ceramic is an inorganic, nonmetallic... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope