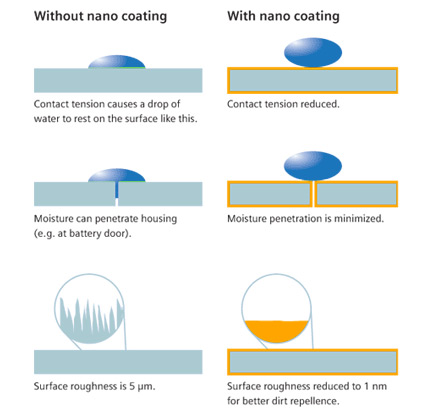

The nano coatings, “liquid solids” composed of extremely tiny particles, possess unique characteristics like extreme flexibility, easy adhesion and resistance to corrosion and microbial growth that could profoundly change the manufacturing process.

Nano coating is getting more popular for special self-cleaning performance

Nano coating is getting more popular for special self-cleaning performance

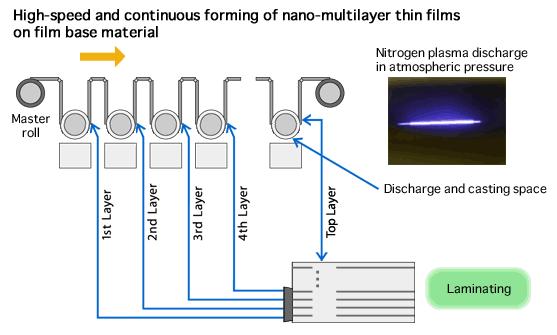

There have been developed various production techniques coping with various uses such as antireflection coating as optical products, water-repelling and oil-repelling films that control adhesion of contamination, transparent conductive film necessary for flat panel displays and antistatic coatings.

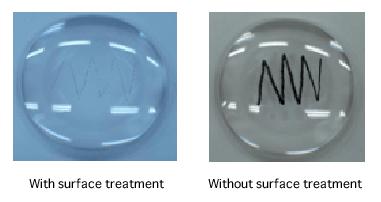

Example of processing flourine-containing water-repelling film

Example of processing flourine-containing water-repelling film

Coating on a material that is not resistant to heat and coating on roll-shaped film have become possible, thereby, high speed production, flexible members and large areas have been made possible.

The same coatings also can be engineered to have superior anti-reflective properties that reduce glare and maximize the amount of light passing through, an effect that shows promise for improving materials used in greenhouses and solar cell panels, the researcher says.

A nano-thin-film lamination forming technology is drawing public attention as a technology indispensable for higher functions of members in a flat panel display field such as liquid crystal, organic EL and electronic paper, as well as in optical fields.

Invisible Wiper

Invisible Wiper

We all know how limited our view is while driving during heavy rain. Raindrops pushing windscreen wipers to the limits of their performance.

Additionally water sprayed by wheels of other vehicles, makes driving even more dangerous.Problem was tackled by German scientists, who invented permanent hydrophobic nano-coating for glass surfaces.

Nano-coating protects the bodywork, increases weather and UV resistance and even reduces corrosion. The car paint remains blemish free for longer and the need for cleaning will be minimised.

Aqueous and oily liquids transporting contaminants are simply repelled surfaces so the adhesion of dirt, dead bugs and other contaminants will is reduced. Sealed car paint becomes easy-to-clean what means that small dose or none cleaning agent is needed.

The Nano-particles adhere directly to the material molecule and allow the surface to deflect any dirt and water. The Nano - hydrophobic treatment is long lasting and can only be removed by damaging the surface.

Zinc oxide nanoparticles have been claimed to be more stable compared with organic UV-blocking agents

Zinc oxide nanoparticles have been claimed to be more stable compared with organic UV-blocking agents

Zinc oxide nanoparticles have been claimed to be more stable compared with organic UV-blocking agents and in nanoparticulate form the increased surface area per unit mass of the zinc oxide coupled with the intense absorption in the UV region should enhance the UV blocking capability of the coating.

Researchers have been developing anti-fog technology for years, but each approach has its drawbacks. Some stores carry special anti-fog sprays that help reduce fogging on the inside of car windows, but the sprays must be constantly reapplied to remain effective. Glass containing titanium dioxide also shows promise for reduced fogging, but the method only works in the presence of ultraviolet (UV) light, researchers say.

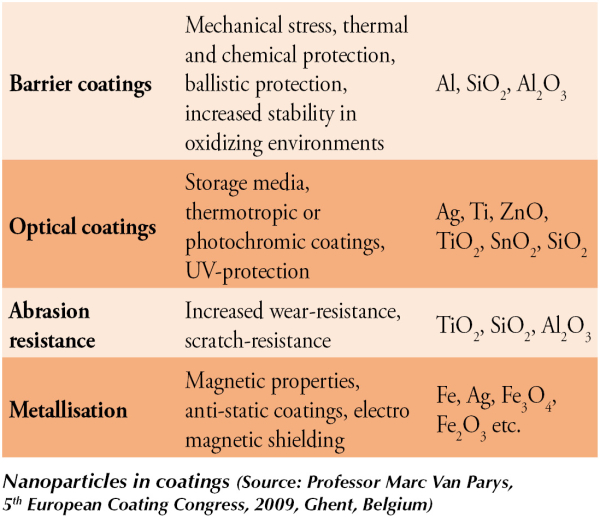

Nanoparticles in coatings

Incorporating multifunctionality into coatings is a very fertile area for innovation. For example, military combat uniforms require multifunctional surface coating protection, typically incorporating ultrahydrophobicity, super-oleophobicity and self-cleaning properties combined with UV-blocking and antimicrobial protection.

Do you need some book`s references about nano technology?here…

You might also like

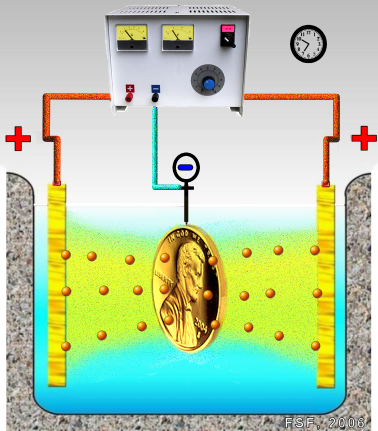

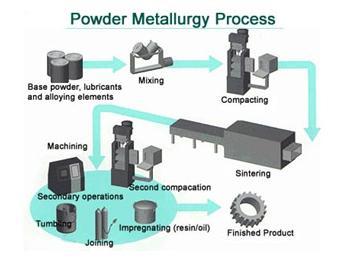

| What is Nanotechnology? Nanotechnology is the engineering... | Metallurgy Glossary Metallurgy Glossary Activity: A function... | Electroplating Electroplating is the process of... | Powder Metallurgy Powder Metallurgy Process, source : https://www.themetalcasting.com/ Powder... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope