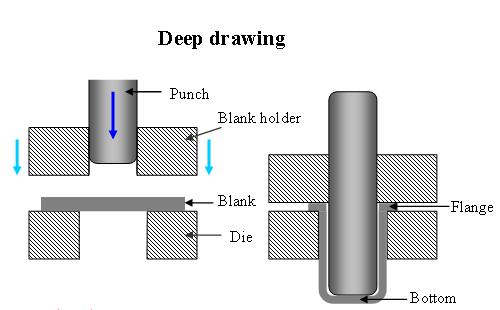

Deep drawing manufacturing technology is the stretching of sheet metal stock, commonly referred to as a blank, around a plug. The edges of the metal blank are restrained by rings and the plug is deep drawn into a top die cavity to achieve the end shape that is desired. There are many shapes that can be made through deep drawing and stamping such as cups, pans, cylinders, domes and hemispheres, as well as irregular shaped products.

Deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

Common shapes for deep drawn products include cylinders for aluminum cans and cups for baking pans. Irregular items, such as enclosure covers for truck oil filters and fire extinguishers, are also commonly manufactured by the deep drawing method.

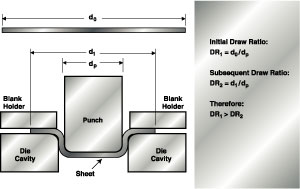

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter.

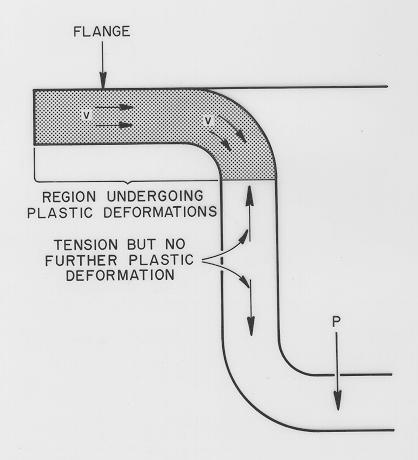

The pattern of deformations in deep drawing

The pattern of deformations in deep drawing

This is achieved by redrawing the part through a series of dies. The flange region (sheet metal in the die shoulder area) experiences a radial drawing stress and a tangential compressive stress due to the material retention property. These compressive stresses (hoop stresses) result in flange wrinkles (wrinkles of the first order). Wrinkles can be prevented by using a blank holder, the function of which is to facilitate controlled material flow into the die radius.

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

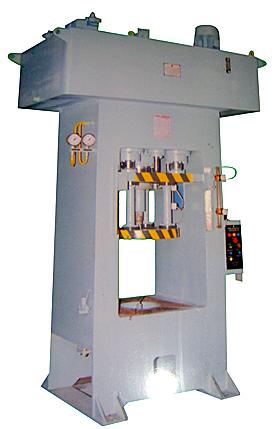

A drawing press can be used for forming sheet metal into different shapes and the finished shape depends on the final position that the blanks are pushed down in. The metal used in deep drawing must be malleable as well as resistant to stress and tension damage. Industries that rely on deep drawing include aerospace, automobile, dairy, lighting, pharmaceuticals, and plastics. Companies that manufacture deep drawn parts require engineer-designed operations and deep drawing presses are relatively expensive.

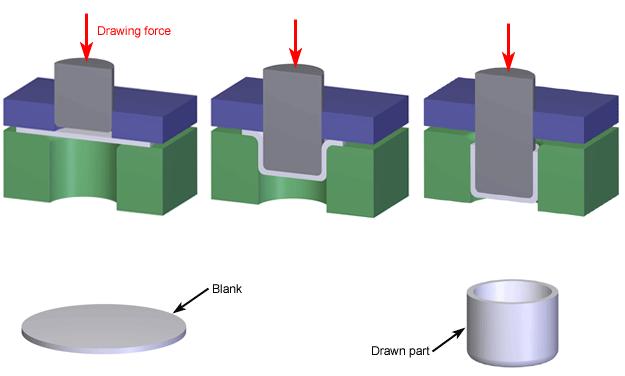

Properly performed, deep drawing can produce a cup such as that shown in (a). However, improper blank holder force can cause fracture (b) or wrinkling (c). The process can also be computer modeled (d).

Accessories such as molds, tooling plates and columns are required to manufacture deep drawn parts. While a mold is needed for stretching the material over the mold‘s edge to produce the required shape,a tooling plate or column is needed as a surface for holding workpieces. Deep drawing differs from metal stamping, since rather than using single piece blanks, metal stamping uses a continuous stream of sheet metal blanks on a strip. Metal spinning, on the other hand, is similar to deep drawing as both metal spinning and drawing operations produce circular and seamless components. Some deep draw technology combines aspects of stamping and spinning in order to provide the most cost-effective manufacturing solution.

In deep drawing, sheet metal is forced into a die by a punch to form a part. The draw ratio decreases throughout the process.

The total drawing load consists of the ideal forming load and an additional component to compensate for friction in the contacting areas of the flange region and bending forces at the die radius. The forming load is transferred from the punch radius through the drawn part wall into the deformation region (sheet metal flange).

Due to tensile forces acting in the part wall, wall thinning is prominent and results in an uneven part wall thickness. It can be observed that the part wall thickness is lowest at the point where the part wall loses contact with the punch, i.e. at the punch radius.

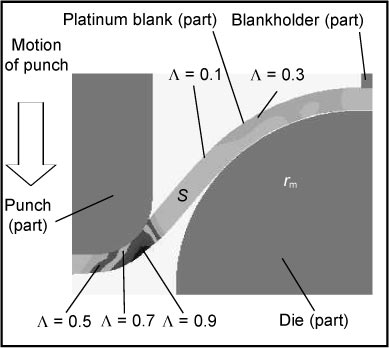

The thinnest part thickness determines the maximum stress that can be transferred to the deformation zone. Due to material volume constancy, the flange thickens and results in blank holder contact at the outer boundary rather than on the entire surface. The maximum stress that can be safely transferred from the punch to the blank sets a limit on the maximum blank size (initial blank diameter in the case of rotationally symmetrical blanks).

Detail of stress-strain calculation for deep drawing of platinum at rm/S = 8

Detail of stress-strain calculation for deep drawing of platinum at rm/S = 8

An indicator of material formability is the limiting drawing ratio (LDR), defined as the ratio of the maximum blank diameter that can be safely drawn into a cup without flange to the punch diameter.

Determination of the LDR for complex components is difficult and hence the part is inspected for critical areas for which an approximation is possible. During severe deep drawing the material work hardens and it may be necessary to anneal the parts in controlled atmosphere ovens to restore the original elasticity of the material.

Commercial applications of this metal shaping process often involve complex geometries with straight sides and radii. In such a case, the term stamping is used in order to distinguish between the deep drawing (radial tension-tangential compression) and stretch-and-bend (along the straight sides) components. Deep drawing is always accompanied by other forming techniques within the press.

Deep drawing Parts

Deep drawing Parts

These other forming methods include trimming, piercing, bulging, reducing, ironing (wall thickness reduction), rolling or beading (often to create O-ring seats), threading, sidewall piercing, crimping, date or pattern stamping and many others.It common use to consider this process as a cost saving alternative to turned parts which require much more raw material.

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope