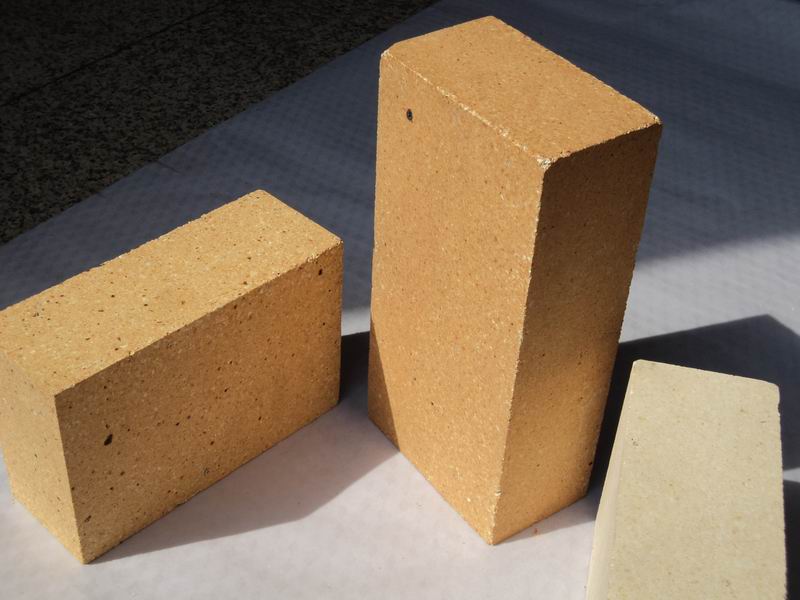

Refractory materials must be chemically and physically stable at high temperatures. Depending on the operating environment, they need to be resistant to thermal shock, be chemically inert, and/or have specific ranges of thermal conductivity and of the coefficient of thermal expansion.

The oxides of aluminium (alumina), silicon (silica) and magnesium (magnesia) are the most important materials used in the manufacturing of refractories. Another oxide usually found in refractories is the oxide of calcium (lime). Fire clays are also widely used in the manufacture of refractories.

Refractories are generally ceramic materials that are capable of withstanding high temperatures. The bulk of refractory materials consist of single or mixed high melting point oxides of elements such as silicon, aluminium, magnesium, calcium and zirconium. Non-oxide refractories also exist and include materials such as carbides, nitrides, borides and graphite. The actual composition of a refractory material is dependent on operating factors such as temperature, atmosphere and what materials it will be in contact with.

Refractories must be chosen according to the conditions they will face. Some applications require special refractory materials. Zirconia is used when the material must withstand extremely high temperatures. The refractoriness of a material is a measure of its ability to withstand exposure to elevated temperatures without undergoing appreciable deformation. It is generally measured using what are called “Seger Cones” which are conical shaped ceramic objects of differing compositions.

When heated to different temperatures, these cones will slump as they soften in response to the temperature, with the degree of slumping being dependent on the composition. A similar cone shaped object is made from the material to be measured and heated along with standard Seger cones. After the conclusion of the heating cycle, the sample material is compared to the Seger cones to gain a comparative measure of its refractoriness. However, it should be noted that when a material is subject to a mechanical load, it may well soften at well below the temperature indicated by the Seger cone test.

Refractories are used to line furnaces and keep heat within the furnace hearth. By using refractories as insulation, the furnace efficiency is increased, the formwork or frame is protected and as are workers needing to pass nearby the furnace.

Furnaces may use a number of layers of different refractories in their construction. For instance, a dense hot face material may be used on the inner surfaces which are exposed to the highest temperatures. Between the hot face refractory and the low density insulation, a number of different layers of intermediate materials may also be employed. Each successive layer (moving away from the hot face) would have an increasingly lower density and more than likely a lower refractoriness compared to the previous layer.

You might also like

| Boron Boron is a non metallic element and the only... | Thermit Welding What is Thermit Welding ? Thermit Welding... | Zirconia Zirconia is an extremely refractory material.... | What is Gold? Gold the Metal Non-Ferrous Gold is a chemical... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope