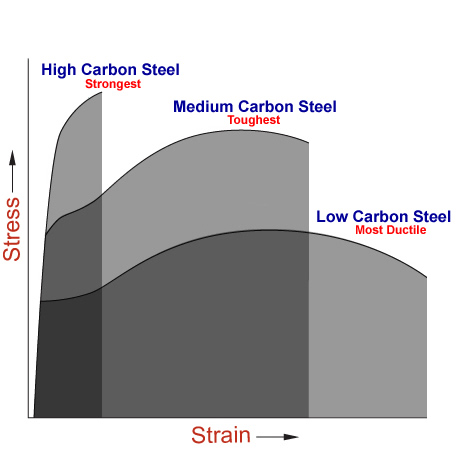

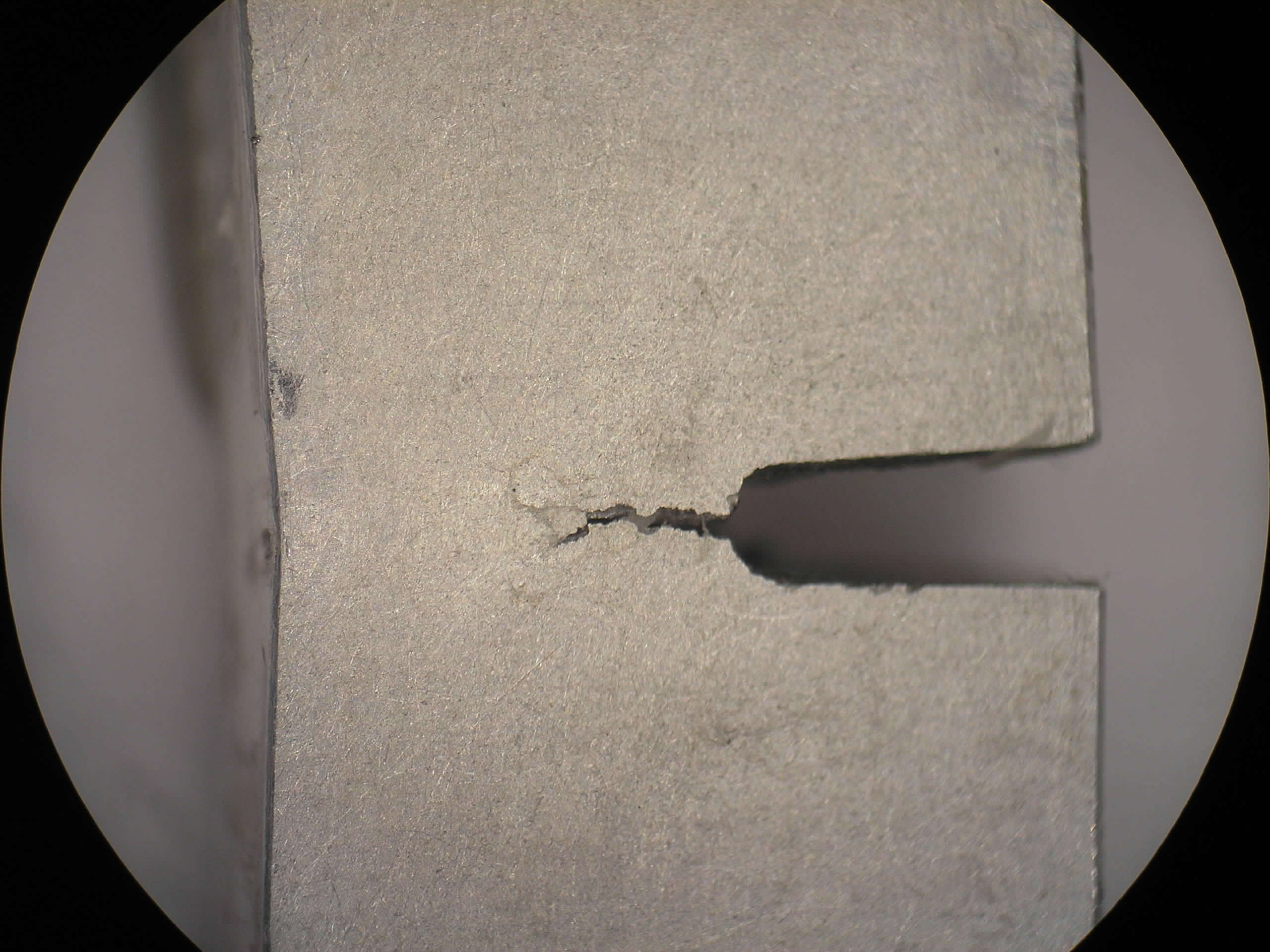

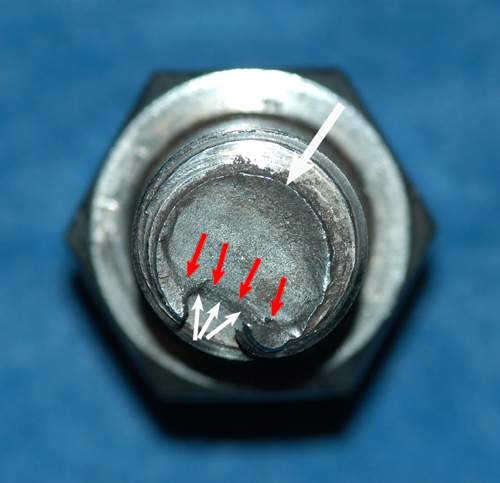

Metals often show quite acceptable properties when small smooth bar specimens are tested in tension at ambient temperature and at slow loading rates. However they fail in a brittle manner when large components are loaded or when the loading is performed at low temperatures or applied rapidly. Susceptibility to brittle fracture is enhanced if notches or other defects are present. Resistance to brittle fracture is commonly referred to as toughness.

Toughness Curve

Toughness Curve

Metals with a body-centred cubic lattice, e.g. pure iron and ferritic steels have the unfortunate characteristic that their fracture mechanism undergoes a dramatic transition with decreasing temperature from a tough ductile mode in the higher temperature region to a brittle cleavage mode at lower temperatures. Face-centred cubic metals, e.g. copper, aluminium and austenitic steels, do not fail by cleavage under all loading conditions and at all temperatures.

You might also like

| Fracture Mechanics Concepts The basis of a fracture mechanics safety... | Welding Procedure A Welding Procedure Specification (WPS)... | Fracture Toughness Fracture mechanics provides a quantitative... | Fatigue Properties When considering the response of metallic... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope