What Are Welding Procedures ?

A Welding Procedure Specification (WPS) is a formal document describing welding procedures. A WPS is developed for each material alloy and for each welding type used. A WPS is supported by a Procedure Qualification Record (PQR or WPQR).

Stages in welding and welder approval

Stages in welding and welder approval

A PQR is a record of a test weld performed and tested (more rigorously) to ensure that the procedure will produce a good weld. Individual welders are certified with a qualification test documented in a Welder Qualification Test Record (WQTR) that shows they have the understanding and demonstrated ability to work within the specified WPS.

According to the American Welding Society (AWS), a WPS provides in detail the required welding variables for specific application to assurerepeatability by properly trained welders. The AWS defines welding PQR as a record of welding variables used to produce an acceptable test weldment and the results of tests conducted on the weldment to qualify a Welding Procedure Specification.

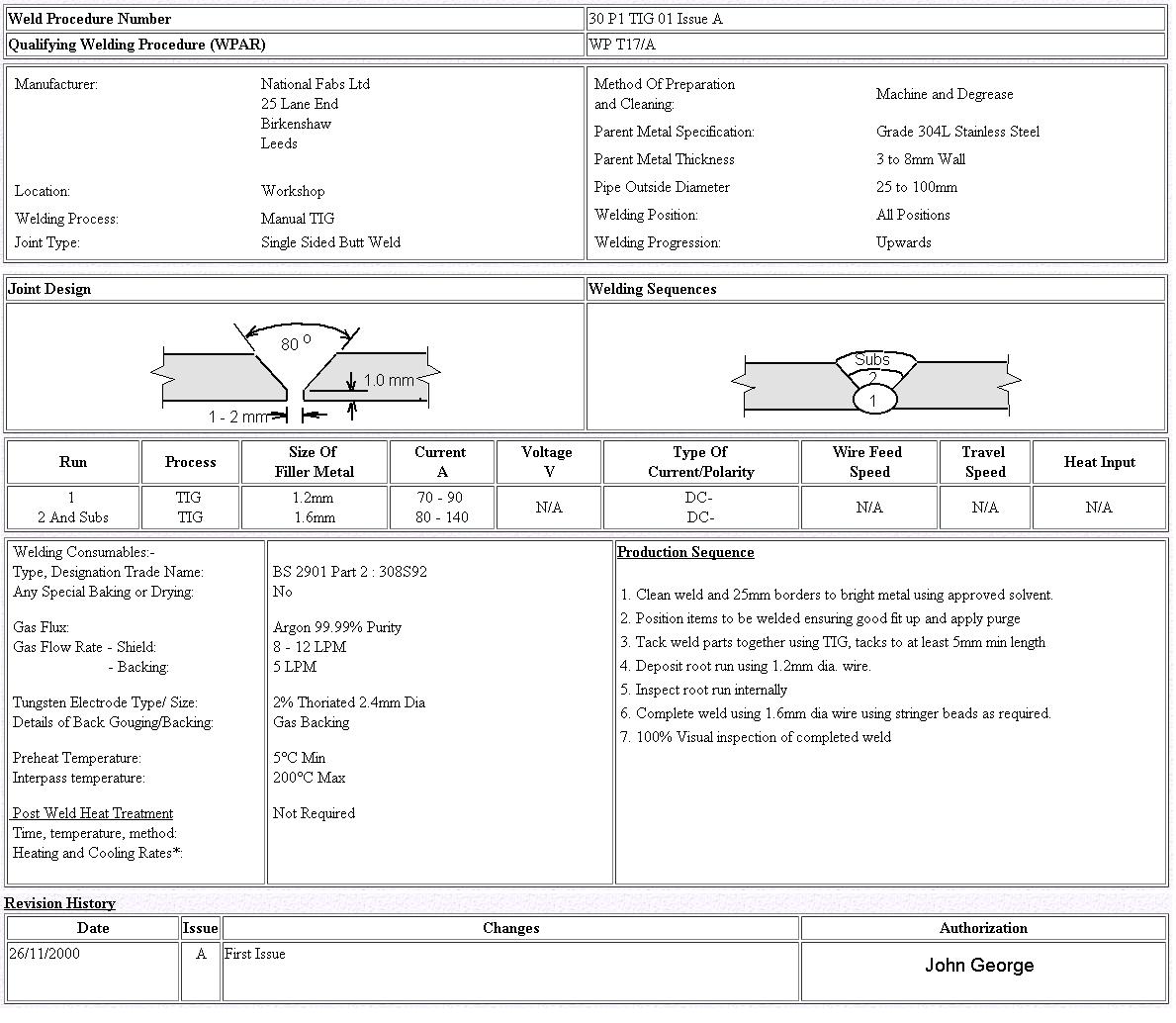

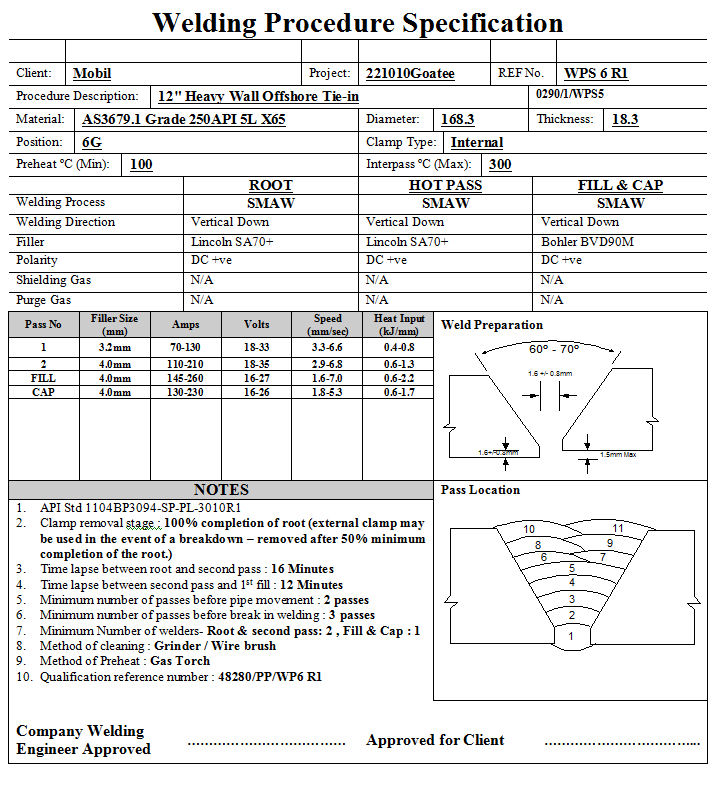

Welding Procedure for Example

Welding Procedure for Example

The American Society of Mechanical Engineers (ASME) similarly defines a WPS as a written document that provides direction to the welder or welding operator for making production welds in accordance with Code requirements.The record also contains the test results of the tested specimens.

In Europe, the European Committee for Standardization (CEN) has adopted the ISO standards on welding procedure qualification (ISO 15607 to ISO 15614) and on welder qualification (ISO 9606), with the exception of qualification for steel welders, where a new version of the old European EN 287-1 standard still applies.

Welding Procedure for Example

Welding Procedure for Example

The same standard defines a Welding Procedure Qualification Record (WPQR) as “Record comprising all necessary data needed for qualification of a preliminary welding procedure specification”. These include: Tested welding consumables (ISO 15610), Previous welding experience (ISO 15611), Standard welding procedure (ISO 15612) and Preproduction welding test (ISO 15613).

Welding is one part of the construction process that requires a number of elements to be in place to assure proper performance. These elements are similar to the essential elements in other industrial processes: appropriate materials must to be used, people performing the work must be capable, procedures must be appropriate for the work, and such procedures must be followed.

Finally, appropriate inspection must take place to ensure that all of these steps have been properly executed. Engineers have many tasks in the course of their review work. Some of those tasks entail review and evaluation of welding documents and records.

You might also like

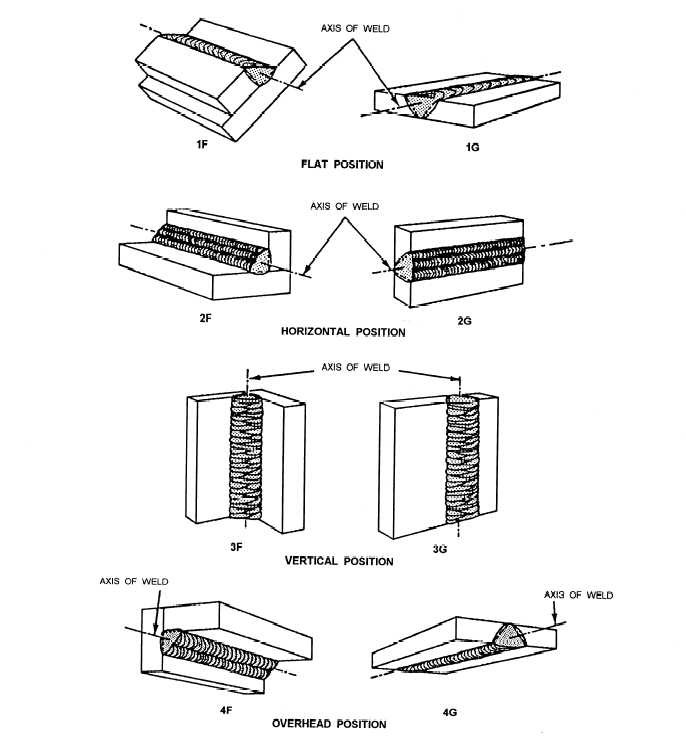

| Welding Positions What`s Kind of Welding Positions ? Welding... | How to weld Titanium ? Welding Titanium Titanium and most titanium... | How to Weld Cast Iron ? Welding Cast Iron Welding cast iron has... | What is TIG WELDING ? TIG Welding - an Overview Gas tungsten arc... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope