Materials Science - Overview

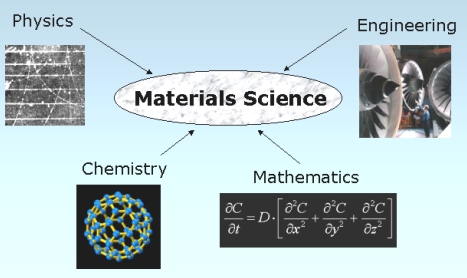

Materials can be natural - like wood, or human-made - like plastic. Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering. This scientific field investigates the relationship between the structure of materials at atomic or molecular scales and their macroscopic properties. With significant media attention focused on nanoscience andnanotechnology in recent years, materials science has been propelled to the forefront at many universities. Materials science also deals with fundamental properties and characteristics of materials.

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering.

Materials science is an interdisciplinary field applying the properties of matter to various areas of science and engineering.

Materials science is an applied science concerned with the relationship between the structure and properties of materials. Chemists who work in the field study how different combinations of molecules and materials result in different properties. They use this knowledge to synthesize new materials with special properties. Eduardo Kamenetzky, a senior research scientist at Cytec Industries, explains, “The central concept of materials science is relating the microstructure of a material to the properties you want it to have. By working with the microstructure, you can tailor the central properties of that material.” Materials scientists are generally employed by industry or in laboratories where the focus is on developing product-related technologies. Barry Speronello, an engineering fellow at Englehard Corporation, agrees, “There are a dozen bad ideas for each fair idea, and a dozen fair ideas for each good idea.

Materials science encompasses various classes of materials, each of which may constitute a separate field. There are several ways to classify materials. For instance by the type of bonding between the atoms. The traditional groups are ceramics, metals and polymers based on atomic structure and chemical composition. New materials has resulted in more classes. One way of classifying materials is:

- Biomaterials

- Ceramics

- Composite materials

- Metals

- Polymers

- Semiconductors

The material of choice of a given era is often and defining point. Phrases such as Stone Age, Bronze Age, and Steel Age are good examples. Originally deriving from the manufacture of ceramics and its putative derivative metallurgy, materials science is one of the oldest forms of engineering and applied science. Modern materials science evolved directly from metallurgy, which itself evolved from mining and (likely) ceramics and the use of fire. A major breakthrough in the understanding of materials occurred in the late 19th century, when the American scientist Josiah Willard Gibbsdemonstrated that the thermodynamic properties related to atomic structure in various phases are related to the physical properties of a material. Important elements of modern materials science are a product of the space race: the understanding and engineering of the metallic alloys, and silica and carbon materials, used in the construction of space vehicles enabling the exploration of space. Materials science has driven, and been driven by, the development of revolutionary technologies such as plastics, semiconductors, and biomaterials.

Materials Science Mystery Of ‘Hidden Order’ Solved

Materials Science Mystery Of ‘Hidden Order’ Solved

Materials science is one of the hottest career areas in science, but to think of it as a single career is misleading. Chemists play a predominant role in materials science because chemistry provides information about the structure and composition of materials as well as the processes to apply and synthesize them. Materials science overlaps to a large extent with polymer science resulting in many new polymeric materials being developed in this century.

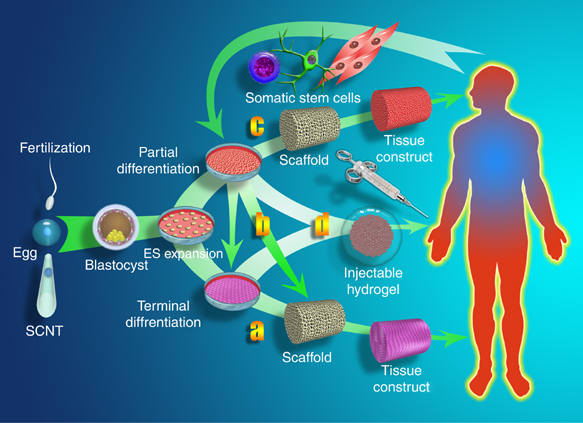

Materials scientists are employed by companies whose products are made of metals, ceramics, and rubber, for example; they work in the coatings (developing new varieties of paint) and biologics industries (designing materials that are compatible with human tissues for prosthetics and implants). Other applications of materials science include studies of superconducting materials, graphite materials, integrated-circuit chips, and fuel cells. Materials science is so interdisciplinary that preparation in a number of related areas is important. “It is good to have a specialization,” says Darrel Tenney, chief of the Materials Division at NASA’s Langley Research Center. Good verbal and written communication skills are required since most materials scientists work in teams with people in other disciplines. The field has since broadened to include every class of materials, including: ceramics, polymers, semiconductors, magnetic materials, medical implant materials and biological materials (materiomics).

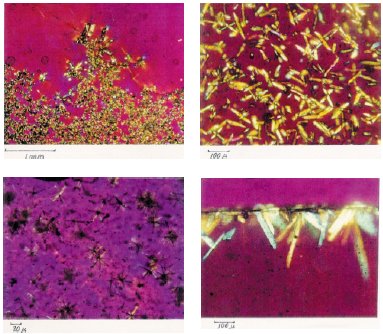

The basis of materials science involves relating the desired properties and relative performance of a material in a certain application to the structure of the atoms and phases in that material through characterization. The manufacture of a perfect crystal of a material is currently physically impossible. Instead materials scientists manipulate the defects in crystalline materials such as precipitates, grain boundaries (Hall-Petch relationship), interstitial atoms, vacancies or substitutional atoms, to create materials with the desired properties.

Foundry - Materials Science Applications

Foundry - Materials Science Applications

“Now, research is much more focused so we look for specific functionalities and applications in materials.” Because the focus is on business, materials scientists say the emphasis of their work is on how to make materials for the marketplace more economically. Some materials scientists are employed by academia and government; however, most are employed by industry.

Not all materials have a regular crystal structure. Glasses, some ceramics, and many natural materials areamorphous, not possessing any long-range order in their atomic arrangements. In addition to industrial interest, materials science has gradually developed into a field which provides tests for condensed matter or solid state theories. New physics emerge because of the diverse new material properties which need to be explained.

Radical materials advances can drive the creation of new products or even new industries, but stable industries also employ materials scientists to make incremental improvements and troubleshoot issues with currently used materials. Industrial applications of materials science include materials design, cost-benefit tradeoffs in industrial production of materials, processing techniques (casting,rolling, welding, ion implantation, crystal growth, thin-film deposition, sintering, glassblowing, etc.), and analytical techniques (characterization techniques such as electron microscopy, x-ray diffraction,calorimetry, nuclear microscopy (HEFIB), Rutherford backscattering, neutron diffraction, small-angle X-ray scattering (SAXS), etc.

Varied Crystals Growing in Chemical Solutions

Varied Crystals Growing in Chemical Solutions

Materials science’s progress is pointing the way toward improved personal economic health and a better way of life. Applications for new materials and modifications of existing materials are expected to keep the demand for trained materials scientists growing. A materials scientist’s background is varied. Materials scientists indicate that students should learn the basic sciences.

“Materials Science encompasses the study of the structure and properties of any material, as well as using this body of knowledge to create new types of materials, and to tailor the properties of a material for specific uses. The field encompasses the spectrum of materials: metals, ceramics, polymers (plastics), semiconductors, and combinations of materials called composites” (Iowa State University, Department of Materials Science and Engineering 2001).

A very comprehensive description of the field of materials science and engineering is contained in the report “Materials Science and Engineering for the 1990s” prepared by the National Research Council’s Committee on Materials Science and Engineering and published by the National Academy Press. Many materials scientists consider this to be a landmark report that has fueled considerable activity in research and development.

In 1999, the National Research Council Committee on Science & Engineering published another report “Materials Science and Engineering: Forging Stronger Links to Users.” “Materials are the foundation and fabric of manufactured products. In fact, many leading commercial products and military systems could not exist without advanced materials and many of the new products critical to the nation’s continued prosperity will come only through the development and commercialization of new materials. Thus, the field of materials science and engineering (MS&E) affects quality of life, industrial competitiveness, and the global environment.”

Materials science heavily relies on physics, chemistry, other engineering fields such as mechanical and electrical engineering. Physical properties of materials are usually the deciding factor in choosing which materials should be used for a particular application. This involves looking at many factors such as: material composition and structure (chemistry), fracture and stress analysis (mechanical engineering), conductivity (electrical engineering), and optical and thermal properties (physics) to name a few.

Besides material characterization, the material scientist/engineer also deals with the extraction of materials and their conversion into useful forms. Often the presence, absence or variation of minute quantities of secondary elements and compounds in a bulk material will have a great impact on the final properties of the materials produced, for instance, steels are classified based on 1/10 and 1/100 weight percentages of the carbon and other alloying elements they contain. The overlap between physics and materials science has led to the offshoot field of materials physics, which is concerned with the physical properties of materials. See important publications in materials physics for more details on this field of study.

Another application of the material sciences is the structures of glass and ceramics, typically associated with the most brittle materials. Most glasses contain a metal oxide fused with silica. At high temperatures used to prepare glass, the material is a viscous liquid. Engineering ceramics are known for their stiffness, high temperature, and stability under compression and electrical stress. Hot pressing provides higher density material. Chemical vapor deposition can place a film of a ceramic on another material. Cermets are ceramic particles containing some metals.

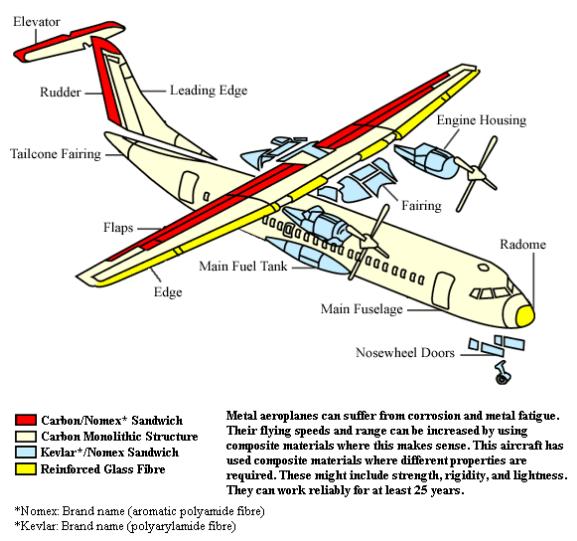

Composite materials are structured materials composed of two or more macroscopic phases. One example is Reinforced Carbon-Carbon (RCC), The light gray material which withstands re-entry temperatures up to 1510 °C (2750 °F) and protects the Space Shuttle’s wing leading edges and nose cap. RCC is a laminated composite material made from graphite rayon cloth and impregnated with a phenolic resin. Polymers are also an important part of materials science. Polymers are the raw materials (the resins) used to make what we commonly call plastics. Plastics are generally classified as “commodity”, “specialty” and “engineering” plastics. The term “additives” in polymer science refers to the chemicals and compounds added to the polymer base to modify its material properties. Engineering plastics are valued for their superior strengths and other special material properties. Specialty plastics are materials with unique characteristics, such as ultra-high strength, electrical conductivity, electro-fluorescence, high thermal stability, etc.

The dividing lines between the various types of plastics is not based on material but rather on their properties and applications. The study of metal alloys is a significant part of materials science. Of all the metallic alloys in use today, the alloys of iron (steel, stainless steel, cast iron, tool steel, alloy steels) make up the largest proportion both by quantity and commercial value. Iron alloyed with various proportions of carbon gives low, mid and high carbon steels. An iron carbon alloy is only considered steel if the carbon level is between 0.01% and 2.00%. Cast Iron is defined as an Iron-Carbon alloy with more than 2.00% but less than 6.67% carbon. Stainless steel is defined as a regular steel alloy with greater than 10% by weight alloying content of Chromium.

Alloy Suppliers

Alloy Suppliers  Aluminum

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope