Chemical Vapour Deposition (CVD)

Chemical vapor deposition (CVD) is a chemical process used to produce high-purity, high-performance solid materials. The process is often used in the semiconductor industry to produce thin films. In a typical CVD process, the wafer (substrate) is exposed to one or more volatile precursors, which react and/or decompose on the substrate surface to produce the desired deposit. Frequently, volatile by-products are also produced, which are removed by gas flow through the reaction chamber.

Chemical vapour deposition or CVD is a generic name for a group of processes that involve depositing a solid material from a gaseous phase and is similar in some respects to physical vapour deposition (PVD).

Light heated CVD reactor, for temperatures of up to 1100K, with high heating rates

Microfabrication processes widely use CVD to deposit materials in various forms, including: monocrystalline, polycrystalline, amorphous, and epitaxial. These materials include: silicon, carbon fiber, carbon nanofibers, filaments, carbon nanotubes, SiO2, silicon-germanium, tungsten, silicon carbide, silicon nitride, silicon oxynitride, titanium nitride, and various high-k dielectrics. The CVD process is also used to produce synthetic diamonds. PVD differs in that the precursors are solid, with the material to be deposited being vaporised from a solid target and deposited onto the substrate.

Types of CVD Processes

CVD covers processes such as :

- Atmospheric Pressure Chemical Vapour Deposition (APCVD)

- Low Pressure Chemical Vapour Deposition (LPCVD)

- Metal-Organic Chemical Vapour Deposition (MOCVD)

- Plasma Assisted Chemical Vapour Deposition (PACVD) or Plasma Enhanced Chemical Vapour Deposition (PECVD)

- Laser Chemical Vapour Deposition (LCVD)

- Photochemical Vapour Deposition (PCVD)

- Chemical Vapour Infiltration (CVI)

- Chemical Beam Epitaxy (CBE)

Precursor gases (often diluted in carrier gases) are delivered into the reaction chamber at approximately ambient temperatures. As they pass over or come into contact with a heated substrate, they react or decompose forming a solid phase which and are deposited onto the substrate. The substrate temperature is critical and can influence what reactions will take place.

Coating Characteristics

CVD coatings are typically :

- Fine grained

- Impervious

- High purity

- Harder than similar materials produced using conventional ceramic fabrication processes

CVD coatings are usually only a few microns thick and are generally deposited at fairly slow rates, usually of the order of a few hundred microns per hour.

CVD Apparatus

A CVD apparatus will consist of several basic components :

- Gas delivery system – For the supply of precursors to the reactor chamber

- Reactor chamber – Chamber within which deposition takes place

- Substrate loading mechanism – A system for introducing and removing substrates, mandrels etc

- Energy source – Provide the energy/heat that is required to get the precursors to react/decompose.

- Vacuum system – A system for removal of all other gaseous species other than those required for the reaction/deposition.

- Exhaust system – System for removal of volatile by-products from the reaction chamber.

- Exhaust treatment systems – In some instances, exhaust gases may not be suitable for release into the atmosphere and may require treatment or conversion to safe/harmless compounds.

- Process control equipment – Gauges, controls etc to monitor process parameters such as pressure, temperature and time. Alarms and safety devices would also be included in this category.

Energy Sources

There are several suitable sources of heat for CVD processes. These include :

- Resistive Heating e.g. tube furnaces

- Radiant Heating e.g. halogen lamps

- Radio Frequency Heating e.g. induction heating

- Lasers

Other energy sources may include UV-visible light or lasers as a source of photo energy.

Precursors

Materials are deposited from the gaseous state during CVD. Thus precursors for CVD processes must be volatile, but at the same time stable enough to be able to be delivered to the reactor. Generally precursor compounds will only provide a single element to the deposited material, with others being volatilised during the CVD process. However sometimes precursors may provide more than one. Such materials simplify the delivery system, as they reduce the number of reactants required to produce a given compound.

Typical Precursor Materials

CVD precursor materials fall into a number of categories such as :

- Halides - TiCl4, TaCl5, WF6, etc

- Hydrides - SiH4, GeH4, AlH3(NMe3)2, NH3, etc

- Metal Alkyls - AlMe3, Ti(CH2tBu)4, etc

- Metal Alkoxides - Ti(OiPr)4, etc

- Metal Dialylamides - Ti(NMe2)4, etc

- Metal Diketonates - Cu(acac)2, etc

- Metal Carbonyls - Ni(CO)4, etc

- Others – include a range of other metal organic compounds, complexes and ligands.

Materials That Can be Produced by CVD Processes

CVD is an extremely versatile process that can be used to process almost any metallic or ceramic compound. Some of these include :

- Elements

- Metals and alloys

- Carbides

- Nitrides

- Borides

- Oxides

- Intermetallic compounds

Applications

CVD has applications across a wide range of industries such as :

- Coatings – Coatings for a variety of applications such as wear resistance, corrosion resistance, high temperature protection, erosion protection and combinations thereof.

- Semiconductors and related devices – Integrated circuits, sensors and optoelectronic devices

- Dense structural parts – CVD can be used to produce components that are difficult or uneconomical to produce using conventional fabrication techniques. Dense parts produced via CVD are generally thin walled and maybe deposited onto a mandrel or former.

- Optical Fibres – For telecommunications.

- Composites – Preforms can be infiltrated using CVD techniques to produce ceramic matrix composites such as carbon-carbon, carbon-silicon carbide and silicon carbide-silicon carbide composites. This process is sometimes called chemical vapour infiltration or CVI.

- Powder production – Production of novel powders and fibres

- Catalysts

- Nanomachines

Some metals (notably aluminium and copper) are seldom or never deposited by CVD. As of 2010, a commercially cost effective, viable CVD process for copper did not exist, though copper formate, copper(hfac)2, Cu(II) ethyl acetoacetate, and other precursors have been used. Copper deposition of the metal has been done mostly by electroplating, in order to reduce the cost. Aluminum can be deposited from tri-isobutyl aluminium (TIBAL), tri ethyl/methyl aluminum (TEA,TMA), or dimethylaluminum hydride (DMAH), but physical vapor deposition methods are usually preferred.

You might also like

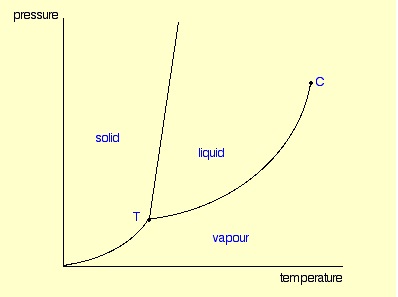

| Physical Vapor Deposition (PVD) What is Physical vapour deposition ? Physical... | What is Sputter Deposition ? Sputtering Deposition Sputtering is a process... | What is “Thin Films” materials ? Advanced Materials : Thin Films Thin film... | The Basic Phase Diagram What is a Phase Diagram ? A phase diagram... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope