Composite materials are formed by combining two or more materials that have quite different properties. The different materials work together to give the composite unique properties, but within the composite you can easily tell the different materials apart – they do not dissolve or blend into each other.

Application of Composite Materials

Application of Composite Materials

Composites exist in nature. A piece of wood is a composite, with long fibres of cellulose (a very complex form of starch) held together by a much weaker substance called lignin. Cellulose is also found in cotton and linen, but it is the binding power of the lignin that makes a piece of timber much stronger than a bundle of cotton fibres.

Humans have been using composite materials for thousands of years. Take mud bricks for example. A cake of dried mud is easy to break by bending, which puts a tension force on one edge, but makes a good strong wall, where all the forces are compressive. A piece of straw, on the other hand, has a lot of strength when you try to stretch it but almost none when you crumple it up. But if you embed pieces of straw in a block of mud and let it dry hard, the resulting mud brick resists both squeezing and tearing and makes an excellent building material. Put more technically, it has both good compressive strength and good tensile strength.

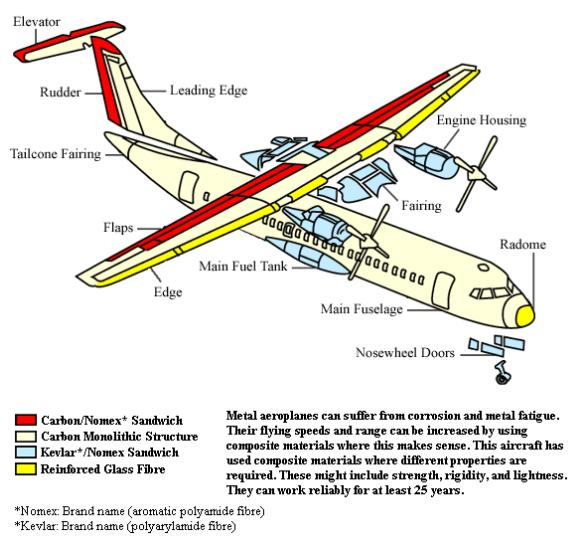

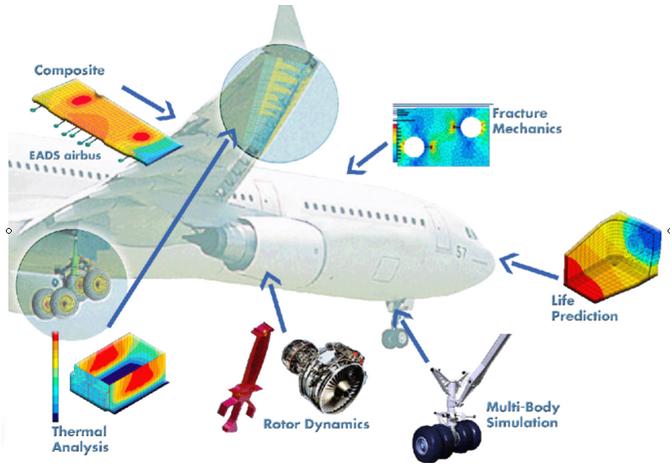

Composite Materials at Airplane

Composite Materials at Airplane

Another well-known composite is concrete. Here aggregate (small stones or gravel) is bound together by cement. Concrete has good strength under compression, and it can be made stronger under tension by adding metal rods, wires, mesh or cables to the composite (so creating reinforced concrete).

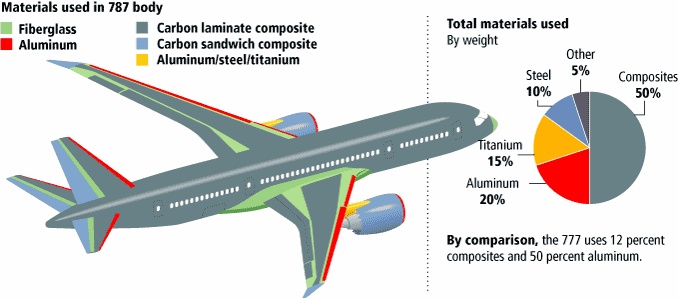

Composite Materials at Boeing 787

Composite Materials at Boeing 787

Most composites are made up of just two materials. One material (the matrix or binder) surrounds and binds together a cluster of fibres or fragments of a much stronger material (the reinforcement). In the case of mud bricks, the two roles are taken by the mud and the straw; in concrete, by the cement and the aggregate; in a piece of wood, by the cellulose and the lignin. In fibreglass, the reinforcement is provided by fine threads or fibres of glass, often woven into a sort of cloth, and the matrix is a plastic.

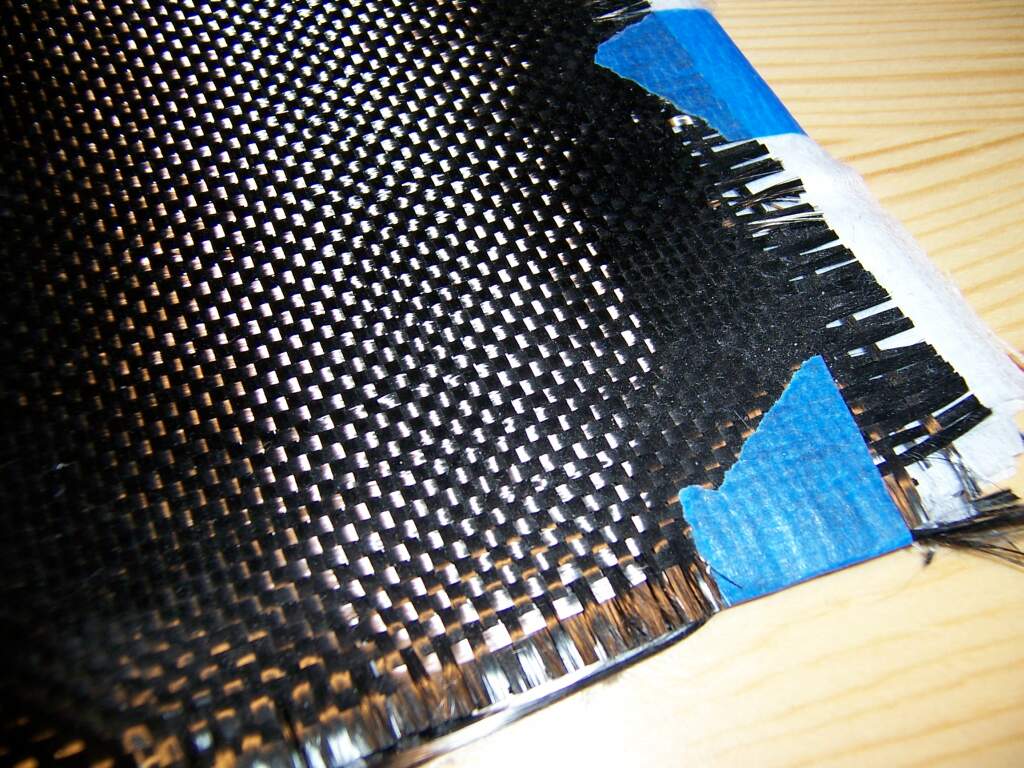

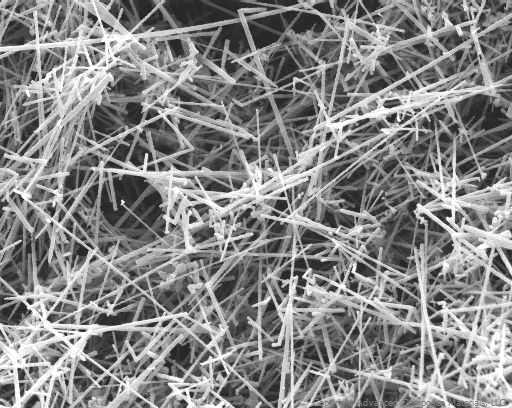

A cloth of woven carbon fiber filaments, a common element in composite materials

A cloth of woven carbon fiber filaments, a common element in composite materials

The threads of glass in fibreglass are very strong under tension but they are also brittle and will snap if bent sharply. The matrix not only holds the fibres together, it also protects them from damage by sharing any stress among them. The matrix is soft enough to be shaped with tools, and can be softened by suitable solvents to allow repairs to be made. Any deformation of a sheet of fibreglass necessarily stretches some of the glass fibres, and they are able to resist this, so even a thin sheet is very strong. It is also quite light, which is an advantage in many applications.

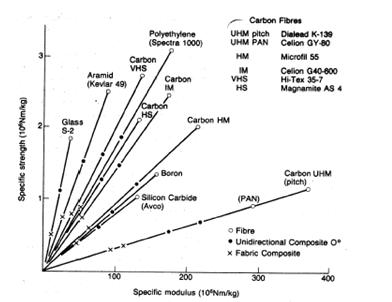

Properties of common reinforcing fibres.Source: Middleton, D.H. (1990) Composite materials in aircraft structures. Longman Scientific and Technical: London.

Over recent decades many new composites have been developed, some with very valuable properties. By carefully choosing the reinforcement, the matrix, and the manufacturing process that brings them together, engineers can tailor the properties to meet specific requirements. They can, for example, make the composite sheet very strong in one direction by aligning the fibres that way, but weaker in another direction where strength is not so important. They can also select properties such as resistance to heat, chemicals, and weathering by choosing an appropriate matrix material.

Composite materials, often shortened to composites, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or microscopic scale within the finished structure.The most visible application is pavement in roadways in the form of either steel and aggregate reinforced Portland cement or asphalt concrete. Those composites closest to our personal hygiene form our shower stalls and bathtubs made of fibreglass. Imitation granite and cultured marble sinks and countertops are widely used. The most advanced examples perform routinely on spacecraft in demanding environments.

Wood is a natural composite of Cellulose fibres in a matrix of lignin. The earliest man-made composite materials were straw and mud combined to form bricks for building construction. The ancient brick-making process can still be seen on Egyptian tomb paintings in the Metropolitan Museum of Art.

Composites are made up of individual materials referred to as constituent materials. There are two categories of constituent materials: matrix and reinforcement. At least one portion of each type is required. The matrix material surrounds and supports the reinforcement materials by maintaining their relative positions. The reinforcements impart their special mechanical and physical properties to enhance the matrix properties. A synergism produces material properties unavailable from the individual constituent materials, while the wide variety of matrix and strengthening materials allows the designer of the product or structure to choose an optimum combination.

Engineered composite materials must be formed to shape. The matrix material can be introduced to the reinforcement before or after the reinforcement material is placed into the mould cavity or onto the mould surface. The matrix material experiences a melding event, after which the part shape is essentially set. Depending upon the nature of the matrix material, this melding event can occur in various ways such as chemical polymerization or solidification from the melted state.

Matrix materials are usually some type of plastic, and these composites are often called reinforced plastics. There are other types of matrices, such as metal or ceramic, but plastics are by far the most common. There are also many types of plastics, but a discussion of them is beyond the scope of this week’s column. Suffice it to say for now that the two most common plastic matrices are epoxy resins and polyester resins.

Composite Materials at Shuttle

Composite Materials at Shuttle

Composite materials are available as plies or lamina. A single ply consists of fibers oriented in a single direction (unidirectional) or in two directions (bidirectional; for example a woven fabric). There are other forms, but these are the most important for this discussion.

Composite properties are best in the direction of the fibers. Perpendicular, or transverse, to the fibers, the matrix properties dominate because load must be transfered by the matrix every fiber diameter. Because most structures are not loaded in a single direction, even though one direction may dominate, it is necessary to orient fibers in multiple directions. This is accomplished by stacking multiple plies together. Such a stack is called a laminate.

Trip to the moon using composite plastic

Trip to the moon using composite plastic

The most efficient composites have most of their fibers oriented in the primary load direction, and just enough fibers oriented in the other directions to carry secondary loads and hold the structure together. Efficiency means both low weight and low cost, because any fibers which don’t carry much load could probably be removed.

You might also like

| Types of Materials Metals: Metals are elements... | Fe-Fe3C T-T-T Diagram Fe-Fe3C T-T-T Diagram, Adapted from... | Bainite Bainite is an acicular microstructure... | Nickel and Nickel Alloys Nickel is a chemical element, with... |

Mister Worker is the online store for professionals where you can buy the best work tools for maintenance and repair operations.

With a 70.000 work tools catalogue, technical sheets, video tutorials and experts' blog, Mister Worker is the new frontier for industrial tools supply and the perfect partner for every Company.

Mister Worker offers technical counselling, custom quotes and exclusive discounts on the complete catalogue of Facom, Stahlwille, DeWalt, Stanley, Knipex, Usag and many other specialized brands.

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope