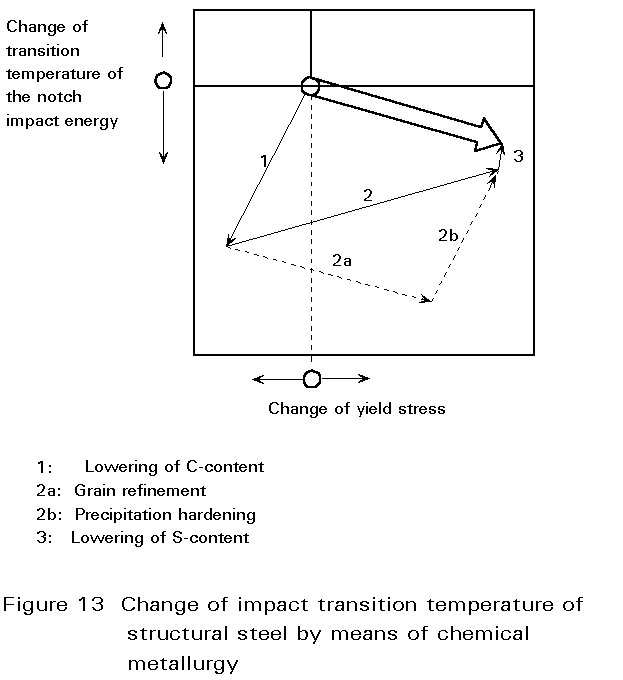

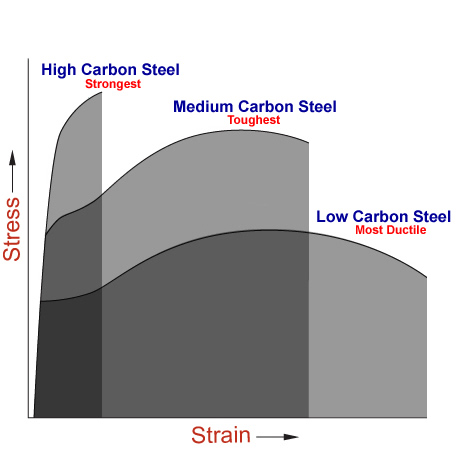

Preceding sections have described the influence of the micro structure on strength and toughness using metallurgical mechanisms. Chemical and physical metallurgy can change microstructural characteristics so that optimum strength and toughness requirements may be obtained. By combining the various treatments it is possible to achieve a wide range of steel properties (Figure 13) :

- Chemical metallurgy treatments

Variation of the chemical composition of a steel by adding alloying elements aims to increase strength and/or increase resistance to brittle fracture. Solid solution hardening generally lowers toughness and is not widely employed.

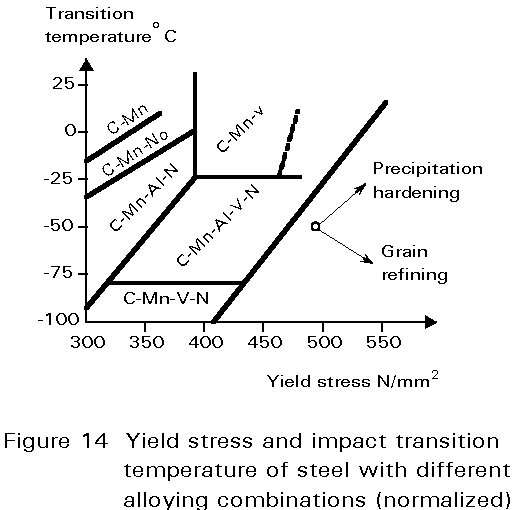

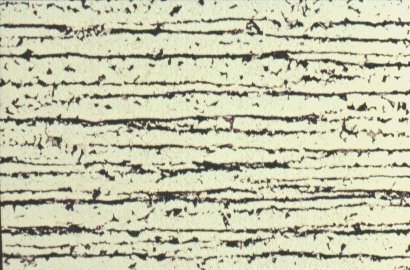

Precipitation hardening also increases strength and decreases toughness. The addition of manganese and nickel produces a small increase in strength due to solution hardening but a more significant reduction is impact transition temperature due to grain refinement (Figure 14).

Alloying with the micro-alloying elements Niobium, (Nb) Vanadium (V) and Titanium (Ti) producing carbides and nitrides simultaneously raises strength by precipitation hardening and toughness by grain refinement. Decreasing the content of elements such as S and P improves the degree of purity, which has positive effects on toughness and weldability.

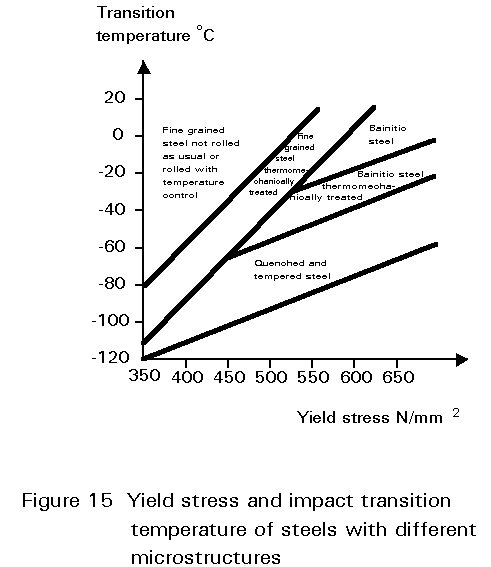

- Physical metallurgy treatments

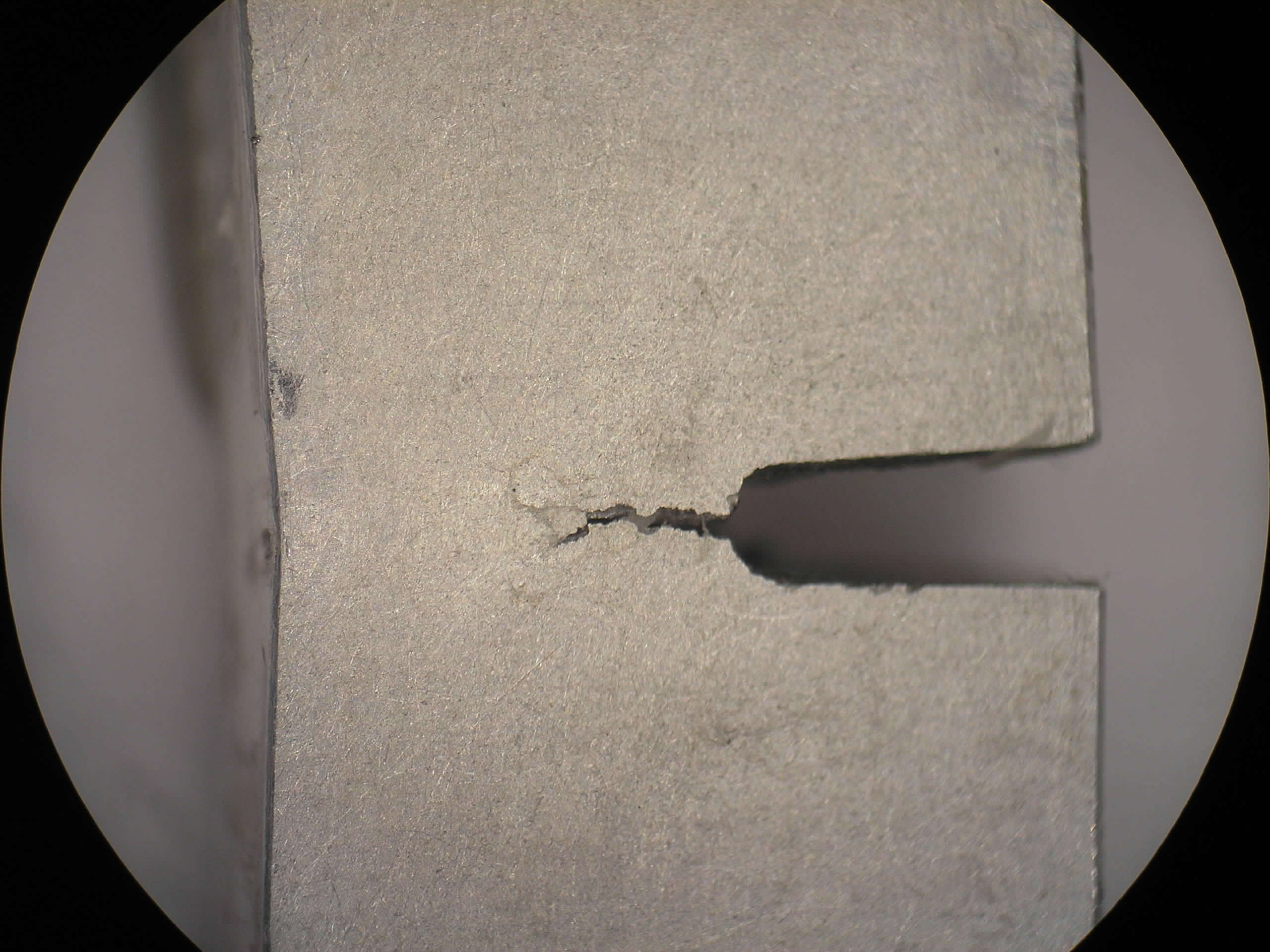

The microstructure of a steel can be greatly affected by heat treatment or forming. Correctly chosen temperature, degree of deformation, time between deformation steps and cooling rate can reduce the grain size and control the state of precipitation, thus raising toughness and strength (Figure 15).

You might also like

| Fracture Mechanics Concepts The basis of a fracture mechanics safety... | Toughness Metals often show quite acceptable properties... | Rapidly Cooled Steels Formation of martensite and bainite Normalising... | Fracture Toughness Fracture mechanics provides a quantitative... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope