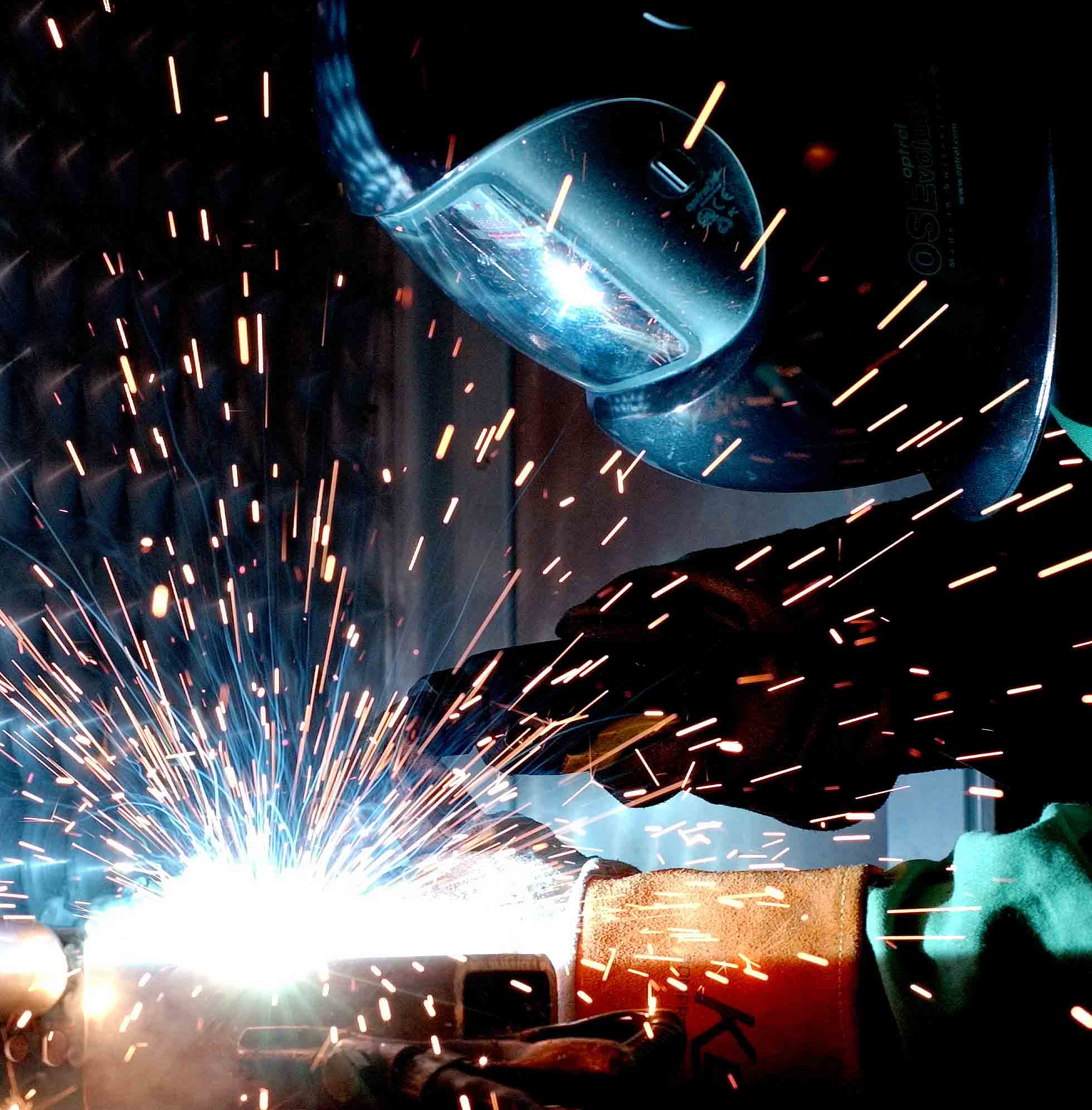

A Brief Description of the Welding Process

Welding is a joining process in which joint production can be achieved with the use of high temperatures, high pressures or both. In this lecture, only the use of high temperatures to produce a joint is discussed since this is, by far, the most common method of welding structural steels.

Welding

Welding

It is essentially a process in which an intense heat source is applied to the surfaces to be joined to achieve local melting. It is common for further “filler metal” to be added to the molten weld pool to bridge the gap between the surfaces and to produce the required weld shape and dimensions on cooling. The most common welding processes for structural steelwork use an electric arc maintained between the filler metal rod and the workpiece to provide the intense heat source.

You might also like

| Welding Welding is a fabrication or sculptural... | Weldability of Structural Steels If weld preparation is good and operator... | Rapidly Cooled Steels Formation of martensite and bainite Normalising... | Structure and Components of Steel The engineering properties of steel,... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope