Ultrasonic Welding

Ultrasonic Welding is the fastest and most cost effective method used today to join and assemble plastic parts and non-ferrous metals. Ultrasonic welding is cost effective and a green technology. Ultrasonic welding eliminates the need to use fasteners, glues and/or solvents.

Ultrasonic Welding Machine

Ultrasonic Welding Machine

Ultrasonic Welding can be used to join all rigid thermoplastics, synthetic fabrics and films. Ultrasonic welding uses an acoustic tool called an ultrasonic horn made to match your parts design. Ultrasonic Welding is converted to heat through friction that melts the plastic or metal.

The main components of an ultrasonic welding system are the actuator and power supply, converter/booster & ultrasonic horn called the stack, part holding weld fixture/jig. Material selection, Surface contact, Field of weld, Joint design, and Welding amplitude are all factors in determining the proper booster and horn design for any given application.

Basic construction of a pneumatic ultrasonic welding machine

Basic construction of a pneumatic ultrasonic welding machine

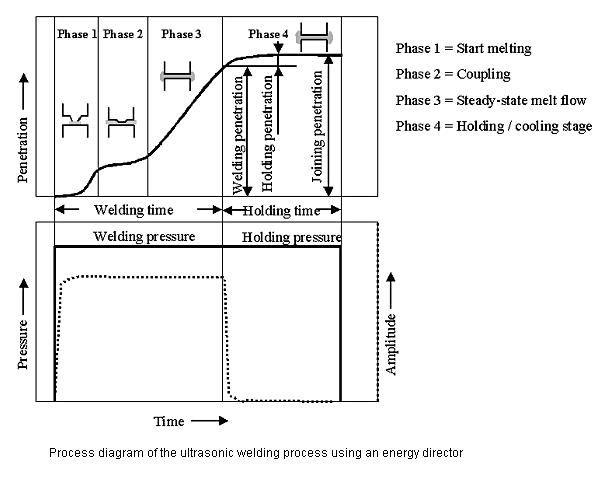

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together.

Ultrasonic welding is an industrial technique whereby two pieces of plastic or metal are joined together seamlessly through high-frequency acoustic vibrations. One component to be welded is placed upon a fixed anvil, with the second component being placed on top. The acoustic energy is converted into heat energy by friction, and the parts are welded together in less than a second.

Ultrasonic welding is unique in that no connective bolts, nails, soldering materials, or adhesives are necessary to bind the two parts together. Because ultrasonic welding is a largely automated process, all a technician needs to do is pull a lever and the welding is complete. The downside of ultrasonic welding is that it only applies to small components - watches, cassettes, plastic products, toys, medical tools, and packaging. The chassis of an automobile, for example, cannot be assembled with ultrasonic welding because the energies involved in welding larger components would be prohibitive.

For joining complex injection molded thermoplastic parts, ultrasonic welding equipment can be easily customized to fit the exact specifications of the parts being welded.

(Note: Common frequencies used in ultrasonic welding of thermoplastics are 15 kHz, 20 kHz, 30 kHz, 35 kHz, 40 kHz and 70 kHz). When welding plastics, the interface of the two parts is specially designed to concentrate the melting process.

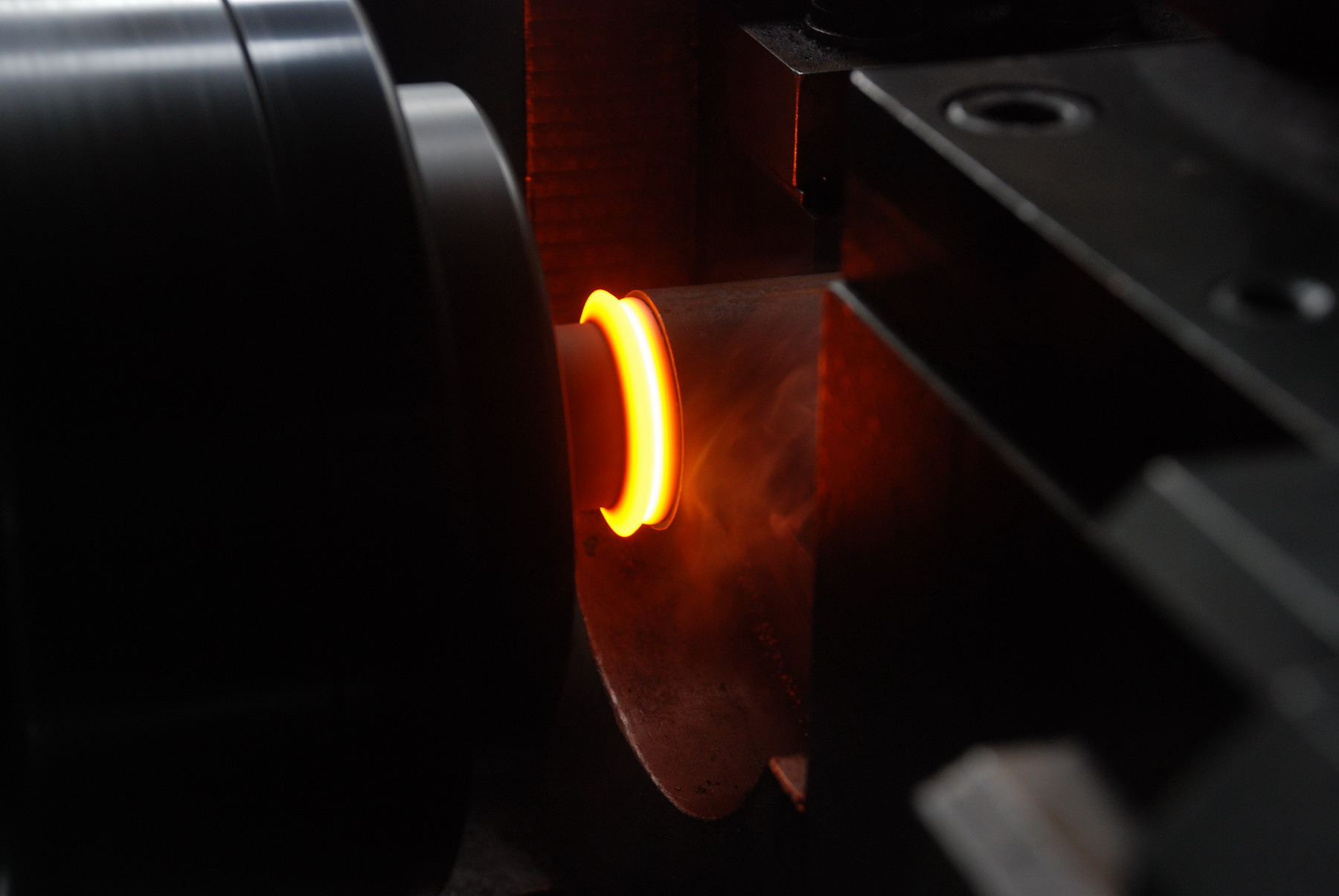

The ultrasonic energy melts the point contact between the parts, creating a joint. Ultrasonics can also be used to weld metals, but are typically limited to small welds of thin, malleable metals, e.g. aluminum, copper, nickel. Ultrasonics would not be used in welding the chassis of an automobile or in welding pieces of a bicycle together, due to the power levels required. Ultrasonic welding of thermoplastics causes local melting of the plastic due to absorption of vibration energy. The vibrations are introduced across the joint to be welded. In metals, Ultrasonic welding occurs due to high-pressure dispersion of surface oxides and local motion of the materials. Vibrations are introduced along the joint being welded.

Practical application of ultrasonic welding for rigid plastics was completed in the 1960s. At this point only hard plastics could be welded. The patent for the ultrasonic method for welding rigid thermoplastic parts was awarded to Robert Soloff and Seymour Linsley in 1965. Soloff, the founder of Sonics & Materials Inc., was a lab manager at Branson Instruments where thin plastic films were welded into bags and tubes using ultrasonic probes. The first car made entirely out of plastic was assembled using ultrasonic welding in 1969. Even though plastic cars did not catch on, ultrasonic welding did. Ultrasonic welding can be used for both hard and soft plastics, such as semicrystalline plastics, and metals. Ultrasonic welding machines also have much more power now. The understanding of ultrasonic welding has increased with research and testing. Ultrasonic welding continues to be a rapidly developing field.

The benefits of ultrasonic welding are that it is much faster than conventional adhesives or solvents. The welding can easily be automated, making clean and precise joints; the site of the weld is very clean and rarely requires any touch-up work.

The applications of ultrasonic welding are extensive and are found in many industries including electrical and computer, automotive and aerospace, medical, and packaging. Ultrasonic welding is a very popular technique for bonding thermoplastics. This type of welding is often used to build assemblies that are too small, too complex, or too delicate for more common welding techniques.

In the electrical and computer industry ultrasonic welding is often used to join wired connections and to create connections in small, delicate circuits. Junctions of wire harnesses are often joined using ultrasonic welding. Electric motors, field coils, transformers and capacitors may also be assembled with ultrasonic welding. Ultrasonic welding of computer disks has been found to have cycle times of less than 300 ms.

Semiconductor devices, transistors and diodes are often connected by thin aluminum and gold wires using ultrasonic welding. One difference between ultrasonic welding and traditional welding is the ability of ultrasonic welding to join dissimilar materials. When creating battery and fuel cell components, thin gauge copper, nickel and aluminum connections, foil layers and metal meshes are often ultrasonically welded together.

For automobiles, ultrasonic welding tends to be used to assemble large plastic and electrical components such as instrument panels, garage door panels, lamps, air ducts, steering wheels, upholstery and engine components. Some of the advantages for ultrasonic welding are low cycle times, automation, low capital costs, and flexibility. Also, ultrasonic welding does not damage surface finish, which is a crucial consideration for many car manufacturers, because the high-frequency vibrations prevent marks from being generated.

Ultrasonic welding is generally utilized in the aerospace industry when joining thin sheet gauge metals and other lightweight materials. Aluminum is a difficult metal to weld using traditional techniques because of its high thermal conductivity. However, it is one of the easier materials to weld using ultrasonic welding because it is a softer alloy metal and thus a solid-state weld is simple to achieve. Many everyday items are either created or packaged using ultrasonic welding techniques. Ultrasonic welding is also applied in the packaging of dangerous materials such as explosives, fireworks and other reactive chemicals.

The food industry finds ultrasonic welding preferable to traditional joining techniques because it is fast, sanitary and can produce hermetic seals. Milk and juice containers are examples of some products that are often sealed using ultrasonic welding.

The paper parts to be sealed are coated with plastic, generally polypropylene or polyethylene, and then welded together to create an airtight seal. For example, if over-welding occurs then the concentration of plastic in the weld zone may be too low and cause the seal to break. If it is under-welded the seal is incomplete. Variations in the thicknesses of materials can cause variations in weld quality. Some other food items that are sealed using ultrasonic welding include candy bar wrappers, frozen food packages and beverage containers.

You might also like

| What is Plastic Welding ? Welding Plastic Definition Plastic welding... | How does Friction Welding Work ? What is Friction Welding ? Friction welding... | Welding Pictures Welding is a fabrication or sculptural process that... | Welding What is Welding ? Welding is a fabrication... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope