Aluminum Corrosion - How it works ?

Corrosion attack on aluminum surfaces is usually quite obvious, since the products of corrosion are white and generally more voluminous than the original base metal. Even in its early stage, aluminum corrosion is evident as general etching, pitting, or roughness of the aluminum surfaces. Aluminum owes its excellent corrosion resistance and its usage as one of the primary metals of commerce to the barrier oxide film that is bonded strongly to its surface and, that if damaged, re-forms immediately in most environments.

On a surface freshly abraded and then exposed to air, the barrier oxide film is only 1 nm thick but is highly effective in protecting the aluminum from corrosion. The natural film can be visualized as the result of a dynamic equilibrium between opposing forces-those tending to form compact barrier layer and those tending to break it down. If the destructive forces are absent, as in dry air, the natural film will consist only of the barrier layer and will form rapidly to the limiting thickness. If the destructive forces are too strong, the oxide will be hydrated faster than it is formed, and little barrier will remain. The corrosion of aluminum is dependent upon a vast number of variables. These variables include environment, temperature, alloy in question, flow velocities, impurities present in the environment, and chemistry conditions to which it is exposed.

An additional factor that affects corrosion of aluminum is pretreatment. Experiments have shown that prefilming limits corrosion on aluminum-clad fuel assemblies. Impurities are major contributors to the corrosion of aluminum. Corrosion products from other plant materials also contribute to the overall inventory of ionic and solid impurities. This problem has been reduced by improved resins and installing filters capable of removing smaller particles. On a surface freshly abraded and then exposed to air, the barrier oxide film is only 1 nm thick but is highly effective in protecting the aluminum from corrosion.

The natural film can be visualized as the result of a dynamic equilibrium between opposing forces-those tending to form compact barrier layer and those tending to break it down. If the destructive forces are absent, as in dry air, the natural film will consist only of the barrier layer and will form rapidly to the limiting thickness. If the destructive forces are too strong, the oxide will be hydrated faster than it is formed, and little barrier will remain.

Between these extremes, where the opposing forces reach a reasonable balance, relatively thick (20 to 200 nm) natural films are formed. Chemistry controls, including pH, dissolved oxygen, and conductivity, greatly influence the formation and propagation of the oxide film on aluminum surfaces. Conductivity is a quantitative indication of the impurities present in the system, and pH theoretically dictates the value of conductivity.

For those reactor plants in which aluminum is used for cladding and other structural components, pH is controlled in an acidic condition because of the corrosion properties of aluminum. In the area of the cladding, the corrosion reduces the thickness and forms an oxide film that is a thermal barrier.

Extensive tests carried out in support of DOE test reactors have revealed that minimum aluminum corrosionresults with a pH of 5.0 at normal operating temperatures. The aluminum corrosion products tend to reduce the substrate (base) aluminum metal corrosion rates. Because it is desirable to maintain dissolved aluminum in the reactor coolant at the lowest practicable level, it is desirable to maintain the system pH level in the range of minimum oxide solubility.

Effects of Composition and Microstructure on Corrosion

- 1xxx Wrought Alloys. Wrought aluminums of the 1xxx series conform to composition specifications that set maximum individual, combined, and total contents for several elements present as natural impurities in the smelter - grade or refined aluminum used to produce these products. Corrosion resistance of all 1xxx compositions is very high, but under many conditions, it decreases slightly with increasing alloy content. Iron, silicon and copper are the elements present in the largest percentages. The copper and part of the silicon are in solid solution.

- 2xxx wrought alloys and 2xxx casting alloys, in which copper is the mayor alloying element, are less resistant to corrosion than alloys of other series, which contain much lower amounts of copper. Alloys of this type were the first heat-treatable high-strength aluminum base materials and have been used for more than 75 years in structural applications, particularly in aircraft and aerospace applications. Much of the thin sheet made of these alloys is produced as an alclad composite, but thicker sheet and other products in many applications require no protective cladding.

- 3xxx Wrought Alloys. Wrought alloys of the 3xxx series (aluminum-manganese and aluminum-manganese-magnesium) have very high resistance to corrosion. The manganese is present in the aluminum solid solution, in submicroscopic particles of precipitate and in larger particles of Al6(Mn,Fe) or Al12(Mn,Fe)3Si phases, both of which have solution potentials almost the same as that of the solid solution matrix.

- 4xxx Wrought Alloys and 3xx.x and 4xx.x Casting Alloys. Elemental silicon is present as second-phase constituent particles in wrought alloys of the 4xxx series, in brazing and welding alloys, and in casting alloys of 3xx.x and 4xx.x series. Corrosion resistance of 3xx.x castings alloys is strongly affected by copper content, which can be as high as 5% in some compositions, and by impurity levels. Modifications of certain basics alloys have more restrictive limits on impurities, which benefit corrosion resistance and mechanical properties.

- 5xxx Wrought Alloys and 5xx.x Casting Alloys. Wrought Alloys of the 5xxx series (aluminum-magnesium-manganese, aluminum-magnesium-chromium, and aluminum-magnesium-manganese-chromium) and casting alloys of the 5xx.x series (aluminum-magnesium) have high resistance to corrosion, and this accounts in part for their use in a wide variety of building products and chemical-processing and food-handling eguipment, as well as applications involving exposure to seawater.

- 6xxx Wrought Alloys. Moderately high strength and very good resistance to corrosion make the heat-treatable wrought alloys of the 6xxx series (aluminum-magnesium-silicon) highly suitable in various structural, building, marine machinery, and process-equipment applications.

- 7xxx Wrought Alloys and 7xx.x casting alloys contain major additions of zinc along with magnesium or magnesium plus copper in combinations that develop various levels of strength. Those containing copper have the highest strengths and have been used as constructional materials, primarily in aircraft applications, for more than 40 years. The copper-free alloys of the series have many desirable characteristics: moderate-to-high strength, excellent toughness, and good workability, formability, and weldability. Use of these copper-free alloys has increased in recent years and now includes automotive applications, structural members and armor plate for military vehicles, and components of other transportation equipment. The 7xxx wrought and 7xx.x casting alloys, because of their zinc contents, are anodic to 1xxx wrought aluminums and to other aluminum alloys. They are among the aluminum alloys most susceptible to SCC.

Resistance to general corrosion of the copper-free wrought 7xxx alloys is good, approaching that of the wrought 3xxx, 5xxx and 6xxx alloys. The copper-containing alloys of the 7xxx series, such as 7049, 7050, 7075, and 7178 have lower resistance to general corrosion than those of the same series that do not contain copper. All 7xxx alloys are more resistant to general corrosion than 2xxx alloys, but less resistant than wrought alloys of other groups.

You might also like

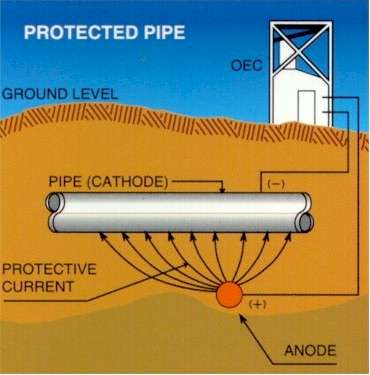

| Corrosion Pictures Corrosion Corrosion is the disintegration... | Aluminum alloys What is Aluminum Alloys ? Aluminium alloys... | Anodizing What is Anodizing ? Anodizing is an electrochemical... | How cathodic protection works Cathodic Protection The basic concept of... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope