How Does Cold Spray Work ?

In the 1990s, cold spraying (often called gas dynamic cold spray) has been introduced. The method was originally developed in Russia with the accidental observation of the rapid formation of coatings, while experimenting with the particle erosion of the target exposed to a high velocity flow loaded with fine powder in a wind tunnel. In cold spraying, particles are accelerated to very high speeds by the carrier gas forced through a converging–diverging de Laval type nozzle.

Cold Metal Spraying

Cold Metal Spraying

Cold spray is one of the many names for describing a solid-state coating process that uses a high-speed gas jet to accelerate powder particles toward a substrate whereby metal particles plastically deform and consolidate upon impact. The term “cold spray” refers to the relatively low process temperature involved—which is typically much lower than the melting point of the spray material.

Upon impact, solid particles with sufficient kinetic energy deform plastically and bond metallurgically to the substrate to form a coating. The critical velocity needed to form bonding depends on the materials properties, powder size and temperature. Soft metals such as Cu and Al are best suited for cold spraying, but coating of other materials (W, Ta, Ti, MCrAlY, WC–Co, etc.) by cold spraying has been reported.

Beneficial characteristics of Cold Spray coatings include :

- Low Temperature Application (in comparison to Thermal Spray processes)

- Very Low Oxidation

- No detrimental impact on temperature-sensitive grain structures (e.g., nano-structured, Amorphous)

- Favorable Compressive Residual Stresses

- Gradient deposits

- Suitable on many substrate materials (metals, glass, composites)

- High Density, Low Porosity coatings (typically <0.5 %)

- Minimal substrate distortion at thicknesses as low as (0.005″)

- Minimal surface preparation needs.

The deposition efficiency is typically low for alloy powders, and the window of process parameters and suitable powder sizes is narrow. To accelerate powders to higher velocity, finer powders (<20 micrometers) are used. It is possible to accelerate powder particles to much higher velocity using a processing gas having high speed of sound (helium instead of nitrogen). However, helium is costly and its flow rate, and thus consumption, is higher. To improve acceleration capability, nitrogen gas is heated up to about 900 C. As a result, deposition efficiency and tensile strength of deposits increase.

Back in the 1980s, during the practical development of cold spray technology, two methods of injecting the spray materials into the nozzle were patented, leading to what is known today as high pressure: injecting the powder prior to the spray nozzle throat from a high-pressure gas supply and low pressure: injecting the powder in the diverging section of the spray nozzle from a low-pressure gas supply.

Operating principle of high-pressure cold spray

In high-pressure cold spray, helium or nitrogen at high pressure, up to 1,000 psi, is preheated-up to 1,000°C-and then forced through a converging-diverging DeLaval nozzle. At the nozzle, the expansion of the gas produces the conversion of enthalpy into kinetic energy, which accelerates the gas flow to supersonic regime—1,000 m/s—while reducing its temperature. The powder feedstock is introduced axially into the gas stream, prior to the nozzle throat. The accelerated solid particles impact the substrate with enough kinetic energy to induce mechanical and/or metallurgical bonding.

Operating principle of low-pressure cold spray

In low-pressure cold spray air or nitrogen at relatively low pressure—80–140 psi—is also preheated, up to 550°C, then forced through a DeLaval nozzle. At the diverging side of the nozzle, the heated gas is accelerated to about 600 m/s. Powder feedstock is introduced downstream in the diverging section and accelerated toward the substrate. As the applicability of cold spray technology expands to new and unique areas of application, there has been an increasing number of commercially available, ready-to-use cold spray systems introduced into the marketplace.

Although the process is still clearly in the experimental stage, the consortium behind cold spray research plan to use the technology to eventually create tough coatings on aircraft engine components and to deposit layers of conductive metals onto substrates for use as heat?tolerant under?bonnet automobile electronics. Other possible uses of the technique include fabricating layer?by?layer low?defect small piece parts, joining chemically dissimilar materials with bonds that gradually make the transition from one material composition to another, and as a low?temperature alternative to welding.

Cold spray technology falls under the larger family of thermal spray processes, and it is not here to replace any of the well-established thermal spray methods. Instead, cold spray technology is expected to supplement and expand the range of applications for thermal spray.

Cold Spray is accepted as a member of the Thermal Spray Family and also known as :

- Gas Dynamic Spray

- High Velocity Powder Deposition

- Kinetic Spraying

- Kinetic Energy Metallization

- Supersonic Particle Deposition

In its current state, cold spray is increasingly used in a variety of industries for corrosion mitigation of sensitive materials, such as: magnesium and aluminum alloys; surface restoration; manufacturing of sputtering targets; fabrication of busbars on heated glass; deposition of WC-Co for hard-chrome replacement coatings; electrical and thermal conductive coatings for transition surfaces; braze joint preparation; and deposition of NiCrAlY bond coats for thermal barriers. For many of these applications, cold spray presents itself as a more economical method because it can actually eliminate or reduce fabrication steps.

The Cold Spray Process is ideal for many types of coatings needs, including :

- Metal Restoration and Sealing - Engine blocks, castings, molds and dies, weld seams, auto body repair, HVAC equipment, refrigeration equipment, heat exchangers

- Thermal Barriers - Aluminum piston heads, manifolds, disc brakes, aircraft engine components

- Thermal Dissipation - Copper or aluminum for heat sinks for microelectronics

- Wear Resistant Coatings - Metallic-ceramic matrix, Solid lubricant Matrix with base metals

- Electronically Conductive Coatings - Copper or aluminum patches on metal, ceramic or polymeric components

- Localized corrosion protection - Zinc or aluminum deposits on affected helms, weldments or other joints

- Biomedical - Biocompatible/bioactive materials on orthopedic implants, prostheses, dental implants

For other applications, cold spray is simply the only viable solution, especially for an increasing number of non-traditional applications. While environmental and health & safety regulations have become more stringent, interest in cold spray has grown as a potentially greener alternative.

You might also like

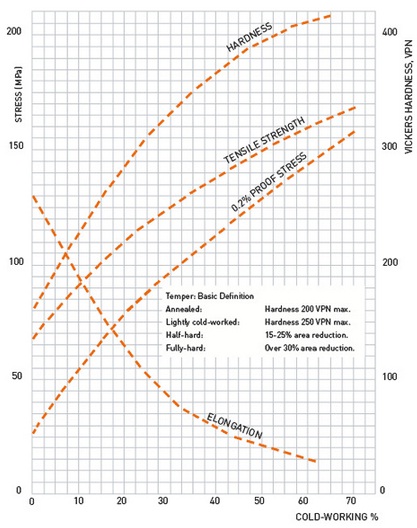

| Metal Spraying What is Metal Spraying ? Metal spraying... | Types of Metal Spraying Metal Spraying Types Thermal Spray, Spray... | Spray Forming Spray forming, also known as spray casting,... | Cold Working Processes Cold Working of Metals Cold working is... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope