What Is Galvanized Steel?

Galvanized steel is steel which has been treated with a rust-resistant zinc coating. It can come in the form of sheets, tubes or rolls, and is available in a variety of thicknesses and strengths. This material is used in manufacturing around the world for products exposed to moisture and adverse weather conditions. Some examples of its use include automobiles, building materials, fencing, and household appliances.

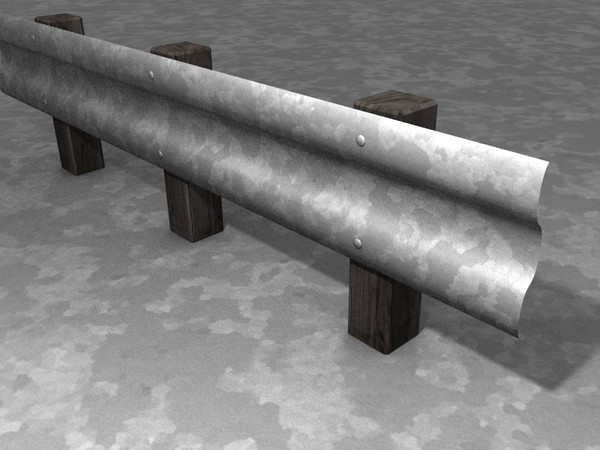

Galvanized steel is widely used in applications where rust resistance is needed, and can be identified by the crystallization patterning on the surface. The construction industry is one of the greatest consumers of galvanized steel products. This material has been used for support beams, piping, heating and air conditioning duct work, barriers and handrails. Metal roofing is popular in some regions because of its durability, rust-resistance, and ability to withstand extreme weather conditions. Unlike asphalt shingles, metal roofs are not easily damaged by hail and heat. It is lightweight, fire-resistant, and recyclable and basically maintenance free.

Many old structures and buildings are piped with galvanized piping for sewage and water transport. However, naturally occurring zinc is impure, and older galvanized pipes were bathed in zinc that also contained lead and other impurities. So, while galvanization was elongating the life of steel pipes, lead and other substances could potentially harm inhabitants. In 1986, Wheatland Tube Company set the precedent for galvanizing with pure zinc by meeting American National Standards Institute (ANSI) standards.

Galvanized Steel

Galvanized Steel

In the past, most homes used galvanized steel pipes for water lines. Some piping is still available to replace parts in older plumbing, but currently these steel pipes are most often used for handrails and support pipes for metal fences, canopies and awnings. The zinc’s temperature is around 850 degrees F and chemically bonds to the steel. Zinc deteriorates at a much slower rate than steel and is an affordable metal for galvanizing steep pipes and other items.

Houses built in climates which experience large amounts of snow or ice are more likely to have gutters made from galvanized steel than vinyl or other alternative materials. Steel buildings are lower-cost construction options which use galvanized steel. Most steel buildings are prepared to accommodate any exterior finish material desired, so the building can blend in with the neighborhood architecture.

The manufacturing of galvanized pipes occurs in two main processes: First, steel pipes are manufactured from raw materials, and then the pipes are galvanized in molten zinc. The finished product is a chemically bonded combination of steel pipes and zinc coating. Manufacturers purchase raw steel products which are milled into steel strips, or sheets. Next, these prefabricated pipes are dipped into molten zinc.

Sheets of hot dipped steel are used for the roof, seats, parking brakes, oil pans and spring housings. Deep drawing steel is ideal for hoods and fenders. Physically, galvanized steel pipes are slightly darker than steel pipes because of zinc’s darker color. While galvanization doesn’t directly strengthen already very strong steel, the zinc coating protects it from breaking down and eventually weakening. Because of this, galvanized steel is used from building skyscrapers to transporting water. Economically, galvanized steel pipes are inexpensive and recyclable.industrial walkways and road grate covers. Galvanized steel sheets are also used in electronic appliances, computers and precision instruments. Other everyday items which can be made from galvanized steel are lights, beds, washtubs, bath tubs, buckets and planters. Backyard grills and garbage cans are often made from steel.

Benefits of Galvanization

Zinc protects steel in two ways. First, it is highly resistant to rust; iron, a major component of steel, reacts very easily with oxygen and moisture and will eventually disintegrate. The layer of zinc on the surface prevents those elements from reaching the steel so quickly. It also develops a patina — a layer of zinc oxides, salts, and other compounds — that offers further protection. Zinc is also extremely durable and scratch resistant, and has a satiny appearance that many find attractive.

The outer layer also protects the steel by acting as a “sacrificial layer.” If, for some reason, rust does take hold on the surface of galvanized steel, the zinc will get corroded first. Even in areas where the surface is scratched or damaged, the surrounding zinc will still corrode before the steel does. The lifespan of galvanized steel varies, but industrial steel with a 3.9 mil (0.0039 inches or 0.09906 mm) thick coating can last more than 70 years without maintenance under average conditions.

Uses

Galvanized steel can be found almost everywhere. Many individuals live in steel frame houses, and buildings are often made with galvanized steel roofs. There are multiple steel parts in cars that help protect them from the weather, and it’s used in many marine applications due to its ability to withstand the salt and the elements. Besides being inexpensive, durable and effective, this metal is also popular because it can be recycled and reused multiple times.

Disadvantages

There are relatively few disadvantages to galvanization, but it’s not a good method for protecting all steel items. Some objects cannot be hot-dipped, often because they are too large or too small, and other forms of galvanizing often are not as protective and long-lasting. Eventually, the zinc will be corroded, although how long this takes depends on the thickness of the coating and the environment. Galvanized steel has a much shorter lifespan when it’s regularly exposed to rain or seawater.

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope