Yield strength definition

Yield strength is the stress at which a specified amount of permanent deformation of a material occurs. When we apply stress to a material, it deforms. Some of the deformation is plastic and the material can recover when the stress is relieved. But some deformation is permanent and the material cannot recover from it.

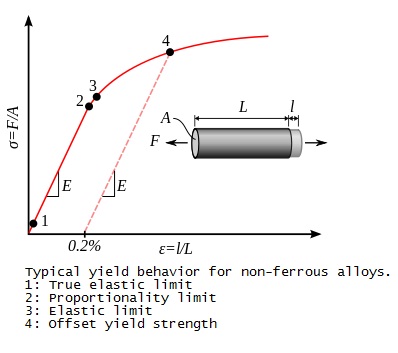

As we apply more stress, there is more deformation. This plots on a curve in a somewhat linear, or proportional, way. But at some point, a bit more stress results in a lot more deformation, and this is the proportional limit of the material. Stress applied beyond this causes an increasing rate of deformation until the maximum or ultimate strength of the material is reached. Yield strength is the stress at which a specified amount of permanent deformation of a material occurs.

When we apply stress to a material, it deforms. Some of the deformation is plastic and the material can recover when the stress is relieved. But some deformation is permanent and the material cannot recover from it. As we apply more stress, there is more deformation. This plots on a curve in a somewhat linear, or proportional, way. But at some point, a bit more stress results in a lot more deformation, and this is the proportional limit of the material. Stress applied beyond this causes an increasing rate of deformation until the maximum or ultimate strength of the material is reached.

The yield strength or yield point of a material is defined in engineering and materials science as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible. In the three-dimensional space of the principal stresses, an infinite number of yield points form together a yield surface.

Knowledge of the yield point is vital when designing a component since it generally represents an upper limit to the load that can be applied. It is also important for the control of many materials production techniques such as forging, rolling, or pressing. In structural engineering, this is a soft failure mode which does not normally cause catastrophic failure or ultimate failure unless it accelerates buckling.

True elastic limit

The lowest stress at which dislocations move. This definition is rarely used, since dislocations move at very low stresses, and detecting such movement is very difficult.

Proportionality limit

Up to this amount of stress, stress is proportional to strain (Hooke’s law), so the stress-strain graph is a straight line, and the gradient will be equal to the elastic modulus of the material.

Elastic limit (yield strength)

Beyond the elastic limit, permanent deformation will occur. The lowest stress at which permanent deformation can be measured. This requires a manual load-unload procedure, and the accuracy is critically dependent on equipment and operator skill. For elastomers, such as rubber, the elastic limit is much larger than the proportionality limit. Also, precise strain measurements have shown that plastic strain begins at low stresses.

Yield point

The point in the stress-strain curve at which the curve levels off and plastic deformation begins to occur.

Offset yield point (proof stress)

When a yield point is not easily defined based on the shape of the stress-strain curve an offset yield point is arbitrarily defined. The value for this is commonly set at 0.1 or 0.2% of the strain. The offset value is given as a subscript, e.g., Rp0.2=310 MPa. High strength steel and aluminum alloys do not exhibit a yield point, so this offset yield point is used on these materials.

Upper yield point and lower yield point

Some metals, such as mild steel, reach an upper yield point before dropping rapidly to a lower yield point. The material response is linear up until the upper yield point, but the lower yield point is used in structural engineering as a conservative value. If a metal is only stressed to the upper yield point, and beyond, Lüders bands can develop.

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope

Hi there,

Thank you for sharing these kind of metallurgical posts. I would like to ask something about this Y Strength

According to you in the third paragraph of the post,

“When we apply stress to a material, it deforms. Some of the deformation is plastic and the material can recover when the stress is relieved. But some deformation is permanent and the material cannot recover from it. ”

I am just wondering, is that ‘Plastic Deformation’ or ‘Elastic Deformation’?

if I am not wrong it is supposed to be ‘Elastic’

Thanks.