Oxy-fuel welding - a Definition

Gas Welding or Oxy-fuel welding are processes that use fuel gases and oxygen to weld and cut metals, respectively. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding.

Pure oxygen, instead of air (20% oxygen/80% nitrogen), is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment.

A common propane/air flame burns at about 3,630 °F (2,000 °C), a propane/oxygen flame burns at about 4,530 °F (2,500 °C), and an acetylene/oxygen flame burns at about 6,330 °F (3,500 °C).

Oxy-fuel is one of the oldest welding processes, though in recent years it has become less popular in industrial applications. However, it is still widely used for welding pipes and tubes, as well as repair work.

It is also frequently well-suited, and favored, for fabricating some types of metal-based artwork. In oxy-fuel welding, a welding torch is used to weld metals.

Welding metal results when two pieces are heated to a temperature that produces a shared pool of molten metal. The molten pool is generally supplied with additional metal called filler. Filler material depends upon the metals to be welded.

You might also like

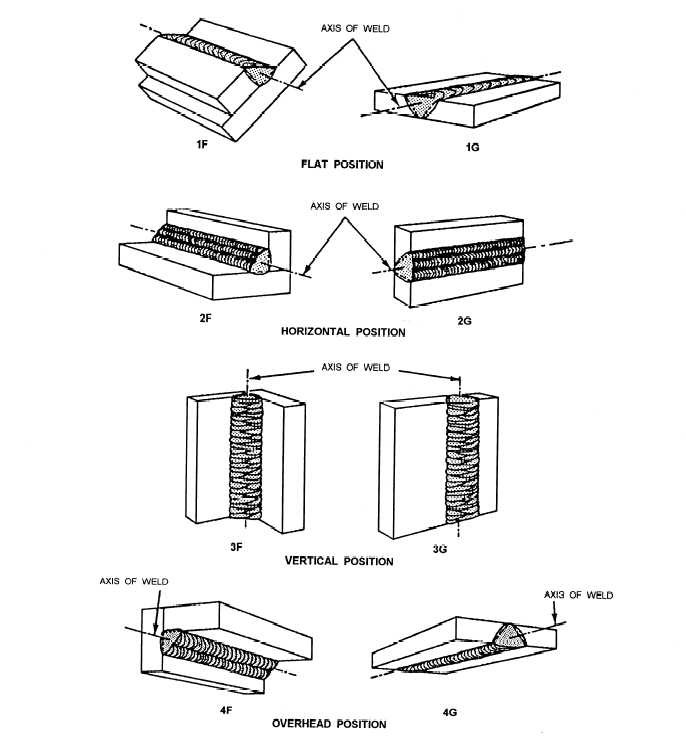

| Welding Procedure What Are Welding Procedures ? A Welding... | Welding Positions What`s Kind of Welding Positions ? Welding... | What is TIG WELDING ? TIG Welding - an Overview Gas tungsten arc... | Arc Welding Welding Arc Overview Arc welding is the... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope