Oxy-fuel welding - a Definition

Gas Welding or Oxy-fuel welding are processes that use fuel gases and oxygen to weld and cut metals, respectively. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903.

Pure oxygen, instead of air (20% oxygen/80% nitrogen), is used to increase the flame temperature to allow localized melting of the workpiece material (e.g. steel) in a room environment.

A common propane/air flame burns at about 3,630 °F (2,000 °C), a propane/oxygen flame burns at about 4,530 °F (2,500 °C), and an acetylene/oxygen flame burns at about 6,330 °F (3,500 °C).

Oxy-fuel is one of the oldest welding processes, though in recent years it has become less popular in industrial applications. However, it is still widely used for welding pipes and tubes, as well as repair work.

It is also frequently well-suited, and favored, for fabricating some types of metal-based artwork. In oxy-fuel welding, a welding torch is used to weld metals.

Welding metal results when two pieces are heated to a temperature that produces a shared pool of molten metal. The molten pool is generally supplied with additional metal called filler. Filler material depends upon the metals to be welded.

In oxy-fuel cutting, a cutting torch is used to heat metal to kindling temperature. A stream of oxygen is then trained on the metal, and metal burns in that oxygen and then flows out of the cut (kerf) as an oxide slag. Torches that do not mix fuel with oxygen (combining, instead, atmospheric air) are not considered oxy-fuel torches and can typically be identified by a single tank (Oxy-fuel welding/cutting generally requires two tanks, fuel and oxygen). Most metals cannot be melted with a single-tank torch. As such, single-tank torches are typically used only for soldering and brazing, rather than welding.

Apparatus

The apparatus used in gas welding consists basically of an oxygen source and a fuel gas source (usually cylinders), two pressure regulators and two flexible hoses (one of each for each cylinder), and a torch. This sort of torch can also be used for soldering and brazing. The cylinders are often carried in a special wheeled trolley. There have been examples of oxyhydrogen cutting sets with small (scuba-sized) gas cylinders worn on the user’s back in a backpack harness, for rescue work and similar. There are also examples of pressurized liquid fuel cutting torches, usually using gasoline. These are used for their increased portability.

Regulator

The regulator is used to control pressure from the tanks to the required pressure in the hose. The flow rate is then adjusted by the operator using needle valves on the torch. Accurate flow control with a needle valve relies on a constant inlet pressure to it. Most regulators have two stages: the first stage of the regulator is a fixed-pressure regulator whose function is to release the gas from the cylinder at a constant intermediate pressure, despite the pressure in the cylinder falling as the gas in the cylinder is used.

Gas hoses

The hoses are specifically designed fobr welding and cutting. The hose is usually a double-hose design, meaning that there are two hoses joined together. These hoses are color-coded for visual identification and their threaded connectors are handed to avoid accidental mis-connection : oxygen is right-handed as normal, fuel gases use a left-handed thread. These left-handed threads also have an identifying groove cut into their nuts.

Non-return valve

Acetylene is not just flammable, it is also a high explosive; it has no upper flammability limit, and the acetylene hose needs no oxygen to power an explosion. If a detonation wave enters the acetylene tank, the tank will be blown apart by the decomposition. Ordinary check valves that normally prevent back flow can not stop a detonation wave as they are not capable of closing before the wave passes around the gate, and for that reason a flashback arrestor is needed. It is designed to operate before the detonation wave makes it from the hose side to the supply side.

Check valve

A check valve lets gas flow in one direction only. Not to be confused with a flashback arrestor, a check valve is not designed to block a shock wave. The pressure wave could occur while the ball is so far from the inlet that the pressure wave gets past before the ball reaches its off position. A check valve is usually a chamber containing a ball that is pressed against one end by a spring: gas flow one way pushes the ball out of the way, and no flow or flow the other way lets the spring push the ball into the inlet, blocking it.

Torches

The torch is the part that the welder holds and manipulates to make the weld. It has a connection and valve for the fuel gas and a connection and valve for the oxygen, a handle for the welder to grasp, a mixing chamber (set at an angle) where the fuel gas and oxygen mix, with a tip where the flame forms.

Welding torch

A welding torch head is used to weld metals. It can be identified by having only one or two pipes running to the nozzle and no oxygen-blast trigger and two valve knobs at the bottom of the handle letting the operator adjust the oxygen flow and fuel flow.

Cutting torch

A cutting torch head is used to cut materials. It is similar to a welding torch, but can be identified by the oxygen blow out trigger or lever. The metal is first heated by the flame until it is cherry red. Once this temperature is attained, oxygen is supplied to the heated parts by pressing the “oxygen-blast trigger”. This oxygen reacts with the metal, forming iron oxide and producing heat. It is this heat which continues the cutting process. The cutting torch only heats the metal to start the process further heat is provided by the burning metal.

Fuels

Oxy-fuel processes may use a variety of fuel gases, the most common being acetylene. Other gases that may be used are propylene, liquified petroleum gas (LPG), propane, natural gas, hydrogen, and MAPP gas. Many brands use different kinds of gases in their mixes.

Acetylene

Acetylene generator as used in Bali by a reaction of calcium carbide with water. This is used where acetylene cylinders are not available. The term ‘Las Karbit’ means acetylene (carbide) welding in Indonesian. Acetylene is the primary fuel for oxy-fuel welding and is the fuel of choice for repair work and general cutting and welding. Acetylene gas is shipped in special cylinders designed to keep the gas dissolved. The cylinders are packed with porous materials (e.g. kapok fibre, diatomaceous earth, or (formerly) asbestos), then filled to around 50% capacity with acetone, as acetylene is acetone soluble. This method is necessary because above 207 kPa (30 lbf/in²) (absolute pressure) acetylene is unstable and may explode. There is about 1700 kPa (250 psi) pressure in the tank when full. Acetylene when combined with oxygen burns at a temperature of 3200 °C to 3500 °C (5800 °F to 6300 °F), highest among commonly used gaseous fuels.

Oxygen

Oxygen is not the fuel. It is what chemically combines with the fuel to produce the heat for welding. This is called ‘oxidation’, but the more specific and more commonly used term in this context is ‘combustion’. In the case of hydrogen, the product of combustion is simply water. For the other hydrocarbon fuels, water and carbon dioxide are produced. The heat is released because the molecules of the products of combustion have a lower energy state than the molecules of the fuel and oxygen. In oxy-fuel cutting, oxidation of the metal being cut (typically iron) produces nearly all of the heat required to “burn” through the workpiece.

Basic Reaction

Oxyfuel gas welding includes any welding process in which the source of heat for welding is the exothermic chemical combustion of a fuel gas with oxygen. While natural gas/methane, propane, propylene, butane, or other hydrocarbon gases, or even hydrogen, can be used. oxyacetylene welding, which uses acetylene gas as the fuel, is the most commonly used oxyfuel gas welding process due to its high flame temperature.

Oxyacetylene welding derives the heat needed to cause melting of the substrates and, almost always, filler from two stages of combustion. In the first stage, known as primary combustion, the acetylene fuel gas partially reacts with oxygen provided from a pressurized gas cylinder to form carbon monoxide and hydrogen :

C2H2 + 02 (cylinder) = 2CO + H2

This reaction is exothermic and is responsible for about one-third of the total heat generated by the complete combustion of acetylene. The dissociation of acetylene to carbon and hydrogen releases 227 kJ/mol of acetylene at 15°C, while the partial combustion of the carbon to form carbon monoxide releases 221 kJ/mol of carbon. No combustion of the hydrogen takes place at this stage. The total heat released by the primary reaction is 448 kJ/mole (501 Btu/ft3) of acetylene.

In the second stage of oxyacetylene or other fuel gas welding, known as secondary combustion, which occurs immediately after the primary combustion, the carbon monoxide resulting from partial combustion of the carbon dissociated from the acetylene (or other fuel gas) reacts further with oxygen, this time from the surrounding air, to form carbon dioxide, while the hydrogen from the primary combustion dissociation of acetylene (or other fuel gas) reacts with oxygen in the air to form water :

2CO + O2(air) = 2C02

H2 + 0.5O2 (air) = H2O

These reactions are also exothermic and are responsible for two-thirds of the total heat generated by burning the dissociation products of the acetylene completely. Burning of hydrogen to produce water vapor releases 242 kJ/mol of hydrogen, while further oxidation of carbon monoxide releases an additional 285 kJ/mol of carbon monoxide, or 570 kJ/mol for the reaction. The total heat released by the second reaction is thus 812 kJ/mol (907 Btu/ft3) of acetylene.

The actual primary and secondary combustion reactions occur in the gas flame of an oxygen-acetylene torch in two distinct regions, as shown in Figure. Primary combustion occurs in an inner cone, while secondary combustion occurs in an outer flame.

Although only accounting for one-third of the total heat of the overall combustion reaction (448 kJ/mol out of 1260 kJ/mole), the inner cone tends to be more concentrated in volume, and so is hotter (i.e., the energy is more dense).

Thus, the welder tends to work with the tip of the inner cone near the workpiece to cause melting, using the outer flame to provide a degree of shielding of the molten weld metal and hot, newly formed weld by the carbon dioxide, to provide preheating to aid in initial melting and to slow down cooling once the weld has been made (thereby sometimes avoiding adverse post-solidification or heat-affected zone transformations.

Similar combustion reactions can be written and energy balances performed for other fuel gas mixtures with oxygen, with different amounts of energy being liberated and different flame temperatures being produced for each. The exact chemical nature, or reactivity, of the flame in oxyfuel gas welding processes, such as oxyacetylene welding, can be adjusted to be chemically neutral, chemically reducing, or chemically oxidizing.

The neutral flame occurs when the molar ratio of acetylene (C2H2) to oxygen (02) is as it should be in the balanced chemical reaction. By supplying excess acetylene to the flame, primary combustion becomes incomplete, leaving some unburned acetylene. The remaining acetylene burns during secondary combustion in the outer flame, producing a tell-tale blue “acetylene feather,” and rendering the flame reducing.

The neutral flame is attained when the flow of oxygen from the pressurized gas cylinder is increased to the point where the feather just disappears. Increasing the flow of oxygen still further results in an oxidizing flame, where there is actually some oxygen left unreacted in the products. The reducing flame is good for removing oxides from metals, such as aluminum or magnesium, that are being welded, and for preventing oxidation reactions during welding, such as decarburization (i.e., C to CO,) in steels. The oxidizing flame causes the metal being welded to form an oxide. This can be useful for preventing the loss of high vapor-pressure components, such as zinc out of brass, through the formation of an impermeable “oxide skin” (here, copper oxide).

Tips and Tricks Gas Welding

Storage and Handling

- Keep cylinders away from physical damage, heat, and tampering.

- Securely chain equipment to prevent falling.

- Store away from flammable and combustible materials.

- Store extra gas and oxygen cylinders separately.

- Store in an upright position.

- Close cylinder valves before moving.

- Protective caps or regulators should be kept in place.

- Roll cylinders on bottom edges to move—Do not drag.

- Allow very little movement when transporting.

General Gas Welding Safety Tips

- Inspect equipment for leaks at all connections using approved leak-test solution.

- Inspect hoses for leaks and worn places.

- Replace bad hoses.

- Protect hoses and cylinders from sparks, flames and hot metal.

- Use a flint lighter to ignite the flame.

- Stand to the side (away from the regulators) when opening cylinder valves.

- Open cylinder valves very slowly to keep sudden high pressures from exploding the regulators.

- Only open the acetylene cylinder valve 1/4 – 3/4 turn; leave wrench in place so the cylinder can be quickly closed in an emergency.

- Open and light acetylene first, then open and adjust oxygen to a neutral flame.

- Follow the manufacturer’s recommendations for shutting off the torch. If the guidelines are not readily available, the common accepted practice is to close the oxygen valve first.

- When finished, close cylinder valves, bleed the lines to take pressure off regulators, neatly coil hoses and replace equipment.

- Have a fire extinguisher easily accessible at the welding site.

Personal Protective Equipment

- Infrared radiation is a cause of retinal burning and cataracts. Protect your eyes with safety glasses.

- Protect your body from welding spatter and arc flash with protective clothing. Such as:

- Woolen clothing

- Flame-proof apron

- Gloves

- Properly fitted clothing that is not frayed or worn.

- Shirts should have long sleeves.

- Trousers should be straight-legged and covering shoes when arc welding.

- Fire resistant cape or shoulder covers are needed for overhead work.

- Check protective clothing equipment before each use to make sure it is in good condition.

- Keep clothes free of grease and oil.

Proper Ventilation

Be sure there is adequate ventilation available when welding in confined areas or where there are barriers to air movement. Natural drafts, fans and positioning of the head can help keep fumes away from the welder’s face.

- The room or welding area contains at least 10,000 cubic feet for each welder.

- The ceiling height is not less than 16 feet.

- Cross ventilation is not blocked by partitions, equipment, or other structural barriers.

- Welding is not done in a confined space.

You might also like

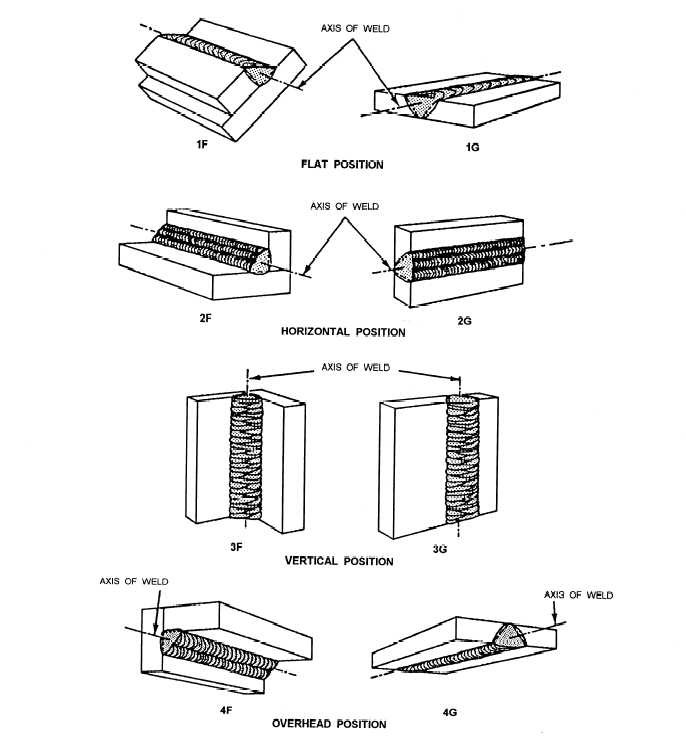

| Welding Procedure What Are Welding Procedures ? A Welding... | Welding Positions What`s Kind of Welding Positions ? Welding... | What is TIG WELDING ? TIG Welding - an Overview Gas tungsten arc... | Arc Welding Welding Arc Overview Arc welding is the... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope