Underwater welding is a type of welding which takes place underwater. A number of different welding techniques can be used underwater, with arc welding being among the most common. There are numerous applications for underwater welding skills, including repairing ships, working on oil platforms, and maintaining underwater pipelines. People with skills and experience in this field can find employment all over the world.

Underwater welding is a type of welding which takes place underwater

Underwater welding is a type of welding which takes place underwater

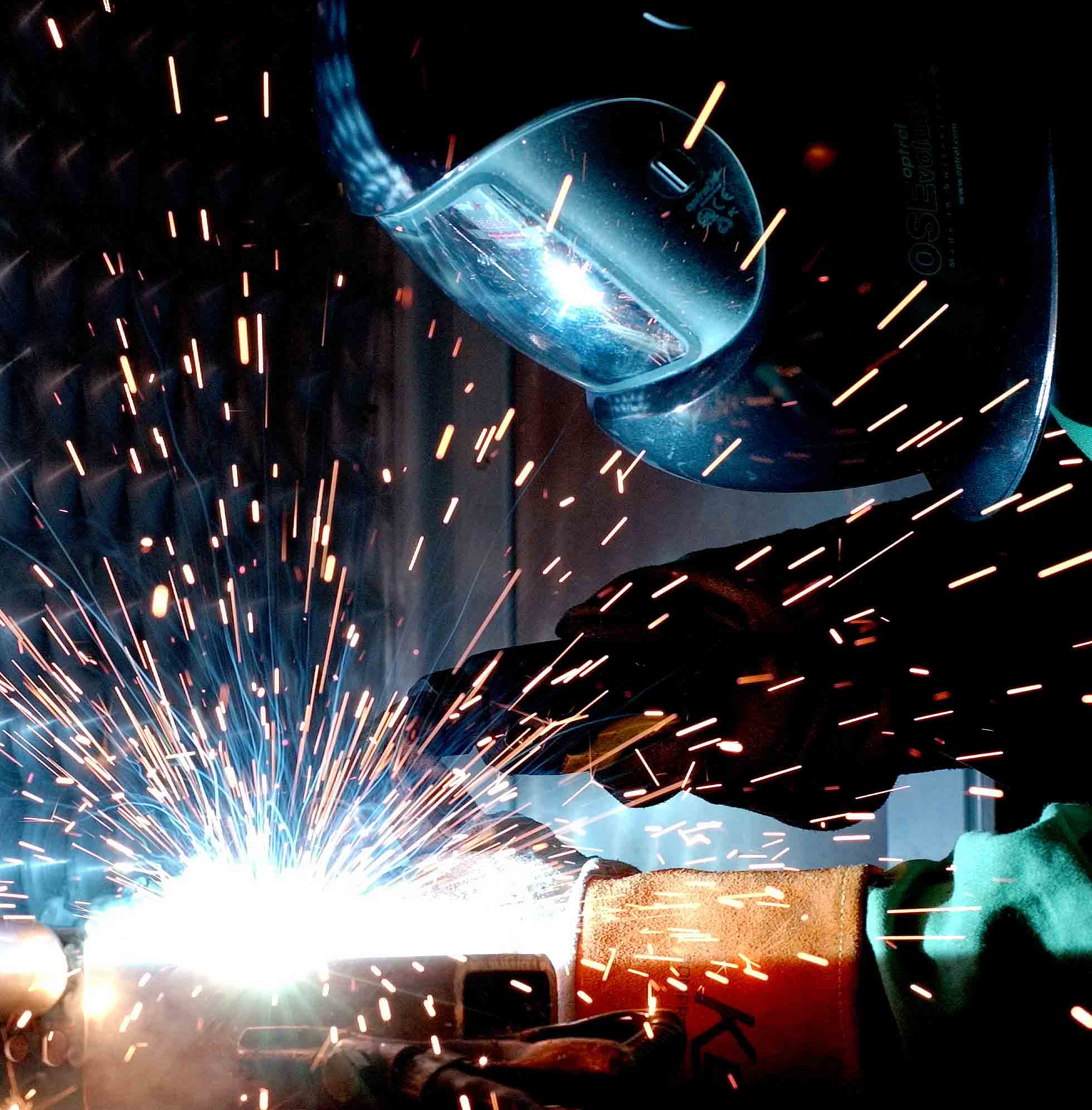

In underwater welding, the environment around the welder is wet. He or she wears a dive suit, and uses welding equipment which has been customized for wet environments. This equipment is designed to be as safe as possible for the welder, reducing the risk of electric shock and the development of dangerous situations. Someone who practices underwater welding must be both a skilled welder and a skilled diver, with the ability to safely and effectively prepare a scene for welding and to confirm that the welds are of high quality.

For some welding situations, a diver may create a dry chamber around the objects being welded. This type of welding is known as hyperbaric welding. Welders performing hyperbaric welding must still have diving skills and the specialized skills to weld at high pressure, but they are not working in an actively wet environment. Constructing a dry chamber can be time consuming, but there are a number of advantages to working in a dry environment which can make hyperbaric welding preferable for certain applications.

This type of welding is known as hyperbaric welding

This type of welding is known as hyperbaric welding

Underwater welding is the process of welding at elevated pressures, normally underwater. Underwater or Hyperbaric welding can either take place wet in the water itself or dry inside a specially constructed positive pressure enclosure and hence a dry environment. It is predominantly referred to as “hyperbaric welding” when used in a dry environment, and “underwater welding” when in a wet environment. The applications of hyperbaric welding are diverse—it is often used to repair ships, offshore oil platforms, and pipelines. Steel is the most common material welded.

The risks of underwater welding include the risk of electric shock to the welder

The risks of underwater welding include the risk of electric shock to the welder

Dry hyperbaric welding is used in preference to wet underwater welding when high quality welds are required because of the increased control over conditions which can be exerted, such as through application of prior and post weld heat treatments. This improved environmental control leads directly to improved process performance and a generally much higher quality weld than a comparative wet weld.

Most welding processes SMAW, FCAW, GTAW, GMAW, PAW could be operated at hyperbaric pressures, but all suffer as the pressure increases

Most welding processes SMAW, FCAW, GTAW, GMAW, PAW could be operated at hyperbaric pressures, but all suffer as the pressure increases

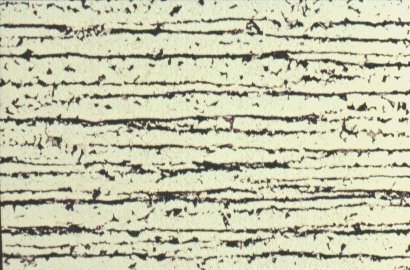

Thus, when a very high quality weld is required, dry hyperbaric welding is normally utilized. Research into using dry hyperbaric welding at depths of up to 1,000 metres (3,300 ft) is ongoing. In general, assuring the integrity of underwater welds can be difficult (but is possible using various nondestructive testing applications), especially for wet underwater welds, because defects are difficult to detect if the defects are beneath the surface of the weld. Dry hyperbaric welding involves the weld being performed at the prevailing pressure in a chamber filled with a gas mixture sealed around the structure being welded.

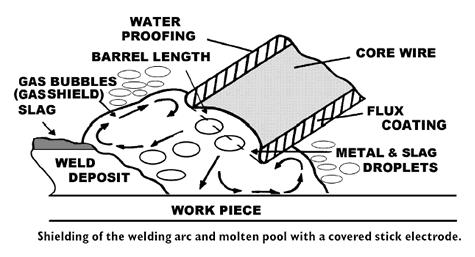

Wet underwater welding commonly uses a variation of shielded metal arc welding, employing a waterproof electrode

Most welding processes SMAW, FCAW, GTAW, GMAW, PAW could be operated at hyperbaric pressures, but all suffer as the pressure increases. Gas tungsten arc welding is most commonly used. The degradation is associated with physical changes of the arc behaviour as the gas flow regime around the arc changes and the arc roots contract and become more mobile. Of note is a dramatic increase in arc voltage which is associated with the increase in pressure. Overall a degradation in capability and efficiency results as the pressure increases.

Wet underwater welding commonly uses a variation of shielded metal arc welding, employing a waterproof electrode.Other processes that are used include flux-cored arc welding and friction welding. In each of these cases, the welding power supply is connected to the welding equipment through cables and hoses. The process is generally limited to low carbon equivalent steels, especially at greater depths, because of hydrogen-caused cracking.

The risks of underwater welding include the risk of electric shock to the welder. To prevent this, the welding equipment must be adaptable to a marine environment, properly insulated and the welding current must be controlled. Commercial divers must also consider the safety issues that normal divers face; most notably, the risk of decompression sickness following saturation diving due to the increased pressure of inhaled breathing gases. Many divers have reported a metallic taste that is related to the breakdown of dental amalgam.There may also be long term cognitive and possibly musculoskeletal effects associated with underwater welding.

For the humans involved, the risks are of three main types. Firstly there is a potential risk to the welder/diver of electric shock. Precautions include achieving adequate electrical insulation of the welding equipment, shutting off the electricity supply immediately the arc is extinguished, and limiting the open-circuit voltage of MMA (SMA) welding sets. Secondly, hydrogen and oxygen are produced by the arc in wet welding and cutting.

Precautions must be taken to avoid the build-up of pockets of gas which are potentially explosive. The other main area of risk is to the life or health of the welder/diver from nitrogen introduced into the blood stream during exposure to air at increased pressure. Precautions include the provision of an emergency air or gas supply, stand-by divers, and decompression chambers to avoid decompression sickness following saturation diving or too rapid return to the surface from a deep dive.

For the structures being welded by wet underwater welding, inspection following welding may be more difficult than for welds deposited in air. Assuring the integrity of such underwater welds may be more difficult, and there is a risk that defects may remain undetected.

You might also like

| Welding Welding is a fabrication or sculptural... | Welding Basic A Brief Description of the Welding Process Welding... | Weldability of Structural Steels If weld preparation is good and operator... | Rapidly Cooled Steels Formation of martensite and bainite Normalising... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope