Welding Arc Overview

Arc welding is the fusion of two pieces of metal by an electric arc between the pieces being joined – the work pieces – and an electrode that is guided along the joint between the pieces. The electrode is either a rod that simply carries current between the tip and the work, or a rod or wire that melts and supplies filler metal to the joint.

Stick Arc Welding

The basic arc welding circuit is an alternating current (AC) or direct current (DC) power source connected by a “work” cable to the work piece and by a “hot” cable to an electrode. When the electrode is positioned close to the work piece, an arc is created across the gap between the metal and the hot cable electrode. An ionized column of gas develops to complete the circuit.

Arc welding is a type of welding that uses a welding power supply to create an electric arc between an electrode and the base material to melt the metals at the welding point. They can use either direct (DC) or alternating (AC) current, and consumable or non-consumable electrodes. The welding region is usually protected by some type of shielding gas, vapor, and/or slag.

A welding process utilizing the concentrated heat of an electric arc to join metal by fusion of the parent metal and the addition of metal to the joint usually provided by a consumable electrode (see illustration). Electric current for the welding arc may be either direct or alternating, depending upon the material to be welded and the characteristics of the electrode used. The current source may be a rotating generator, rectifier, or transformer and must have transient and static volt-ampere characteristics designed for arc stability and weld performance.

There are three basic welding methods: manual, semiautomatic, and automatic. Manual welding is the oldest method, and though its proportion of the total welding market diminishes yearly, it is still the most common. Here an operator takes an electrode, clamped in a hand-held electrode holder, and manually guides the electrode along the joint as the weld is made. Usually the electrode is consumable; as the tip is consumed, the operator manually adjusts the position of the electrode to maintain a constant arc length.

Semiautomatic welding is becoming the most popular welding method. The electrode is usually a long length of small-diameter bare wire, usually in coil form, which the welding operator manually positions and advances along the weld joint. The consumable electrode is normally motor-driven at a preselected speed through the nozzle of a hand-held welding gun or torch.

Automatic welding is very similar to semiautomatic welding, except that the electrode is automatically positioned and advanced along the prescribed weld joint. Either the work may advance below the welding head or the mechanized head may move along the weld joint.

The arc produces a temperature of about 3600°C at the tip and melts part of the metal being welded and part of the electrode. This produces a pool of molten metal that cools and solidifies behind the electrode as it is moved along the joint.

There are two types of electrodes. Consumable electrode tips melt, and molten metal droplets detach and mix into the weld pool. Non-consumable electrodes do not melt. Instead, filler metal is melted into the joint from a separate rod or wire.

The strength of the weld is reduced when metals at high temperatures react with oxygen and nitrogen in the air to form oxides and nitrides. Most arc welding processes minimize contact between the molten metal and the air with a shield of gas, vapour or slag. Granular flux, for example, adds deoxidizers that create a shield to protect the molten pool, thus improving the weld.

The electricity-consuming device – the key component of the arc welding apparatus – is the power source. Electrical consumption from the approximately 110 000 to 130 000 arc welding machines in use in Canada is estimated at 100 GWh a year.

In the past, power sources used transformer-rectifier equipment with large step-down transformers that made them heavy and prone to overheating. They can be used for only one function, i.e., one type of welding. In the 1990s, advances in power switching semiconductors led to the development of inverter power sources that are multi-functional, lighter, more flexible and that provide a superior arc.

Gas metal arc welding (GMAW), commonly called MIG (Metal Inert Gas), is a semi-automatic or automatic welding process with a continuously fed consumable wire acting as both electrode and filler metal, along with an inert or semi-inert shielding gas flowed around the wire to prevent the weld site from contamination.

Constant voltage, direct current power source is most commonly used with GMAW, but constant current alternating current are used as well. With continuously fed filler electrodes, GMAW offers relatively high welding speeds, however the more complicated equipment reduces convenience and versatility in comparison to the SMAW process.

Originally developed for welding aluminium and other non-ferrous materials in the 1940s, GMAW was soon economically applied to steels.

Today, GMAW is commonly used in industries such as the automobile industry for its quality, versatility and speed. Because of the need to maintain a stable shroud of shielding gas around the weld site, it can be problematic to use the GMAW process in areas of high air movement such as outdoors.

Flux-cored arc welding (FCAW) is a variation of the GMAW technique. FCAW wire is actually a fine metal tube filled with powdered flux materials. An externally supplied shielding gas is sometimes used, but often the flux itself is relied upon to generate the necessary protection from the atmosphere. The process is widely used in construction because of its high welding speed and portability.

Submerged arc welding (SAW) is a high-productivity welding process in which the arc is struck beneath a covering layer of granular flux. This increases arc quality, since contaminants in the atmosphere are blocked by the flux. The slag that forms on the weld generally comes off by itself and, combined with the use of a continuous wire feed, the weld deposition rate is high.

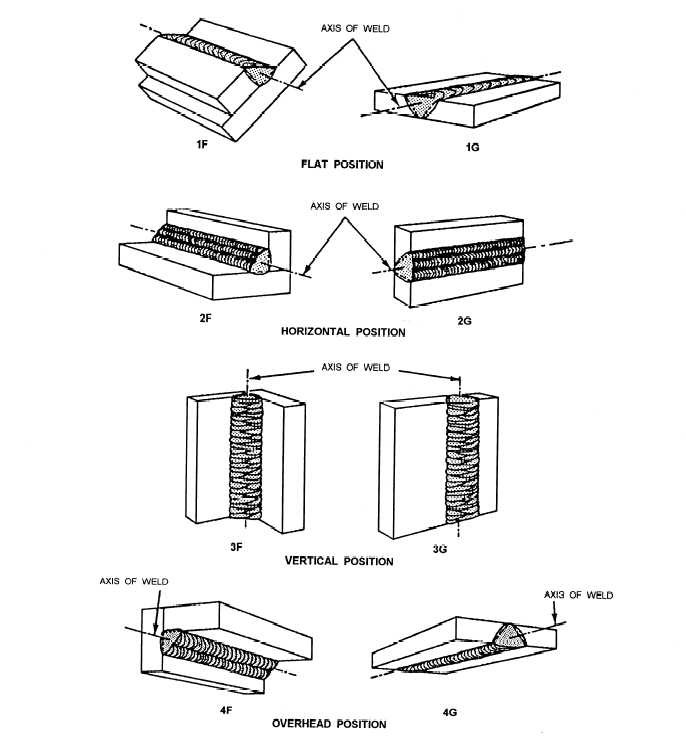

Working conditions are much improved over other arc welding processes since the flux hides the arc and no smoke is produced. The process is commonly used in industry, especially for large products. As the arc is not visible, it typically automated. SAW is only possible in the 1F (flat fillet), 2F, (horizontal fillet), and 1G (flat groove) positions.

Welding power sources use electricity when welding (arc-on) and when idling. Earlier transformer-rectifier equipment had energy conversion efficiencies that ranged from 40 to 60 percent and required idling power consumption of 2 to 5 kW. Modern inverter power sources have energy conversion efficiencies near 90 percent, with idling power consumption in the order of 0.1 kW.

Modern inverter power sources are gradually replacing transformer-rectifier units. They combine a quick return on investment, and, compared with transformer-rectifier units, are far more portable and easier to operate, are multi-functional rather than mono-functional, create superior arcs and combine higher-quality welds with longer arc-on time.

You might also like

| Welding Procedure What Are Welding Procedures ? A Welding... | What is TIG WELDING ? TIG Welding - an Overview Gas tungsten arc... | Welding Positions What`s Kind of Welding Positions ? Welding... | Welding Welding is a fabrication or sculptural process... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope