Zinc Alloys

What is Zinc Alloy ?

Zinc Alloys are combinations of zinc with one or more other metals. If zinc is the primary constituent of the alloy, it is a zinc-base alloy. Zinc also is commonly used in varying degrees as an alloying component with other base metals, such as copper, aluminum, and magnesium. A familiar example of the latter is the association of varying amounts of zinc (up to 45%) with copper to produce brass.

Zinc Alloy Buckle

Zinc Alloy Buckle

Zinc, a crystalline metal with moderate strength and ductility, is seldom used alone except as a coating. After iron, aluminium and copper, zinc is usually the fourth-most used metal. There are many wrought alloys with various alloying elements to improve workability and strenght. There are two major Zinc alloy groups for casting. The first is a standard casting alloy that is primarily Zinc in a hypo-eutectic alloy with less than 5% Aluminum. The Second is the newer group of Zinc-Aluminum alloys. These are hyper-eutectic alloys with up to 27% Aluminum. Both groups are primarily used in die casting.

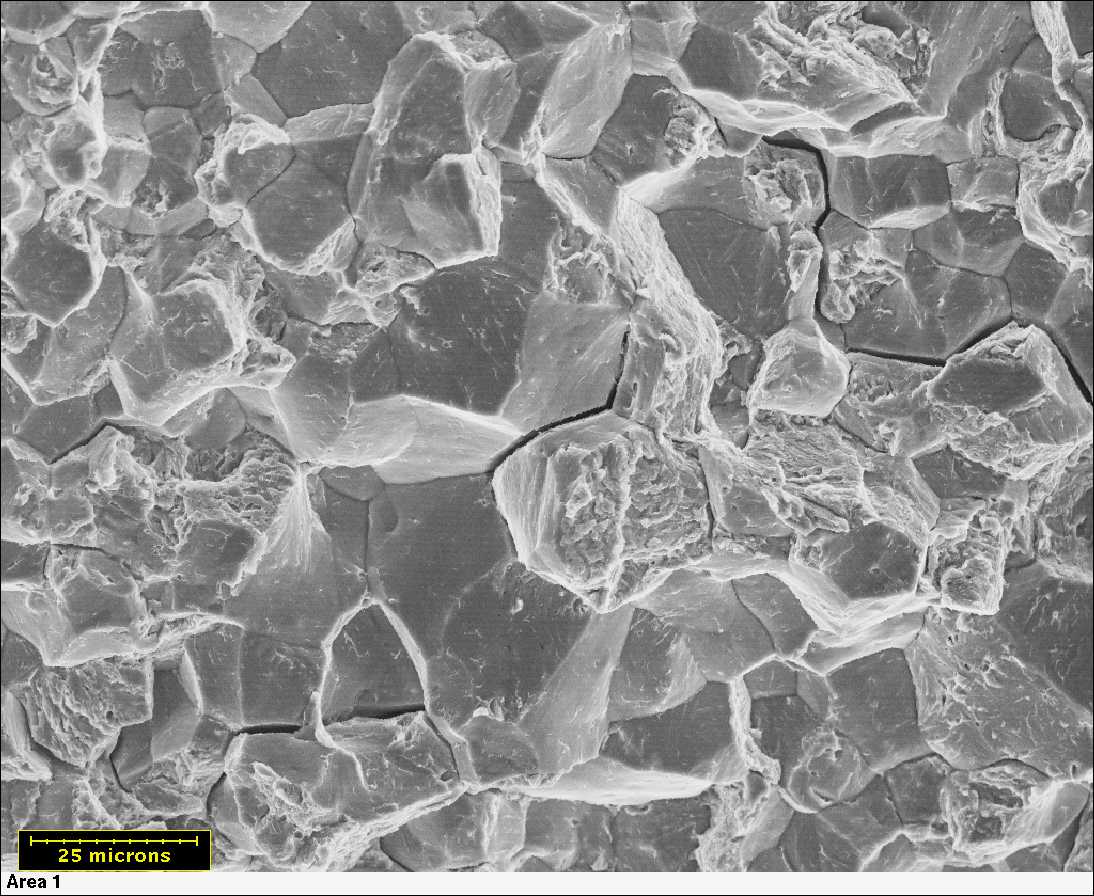

The modern development started during the 80’s with the first alkaline Zn/Fe (99,5%/0,5%) deposits and Zn/Ni (94%/6%) deposits. Recently, the reinforcement of the corrosion specifications of the major European Car Makers and the Directive ELV that banished the use of hexavalent Chromium (CrVI) Conversion Coating required greater use of alkaline Zn/Ni between 12 and 15% of Ni (Zn/Ni 86/14). Only Zn/Ni (86%/14%) is an alloy while lower content of Iron, Cobalt and Nickel leads to co-deposits. Zn/Ni (12%-15%) in Nickel in acidic and alkaline electrolytes is plated as the gamma crystalline phase of the binary diagram Zn-Ni.

Wrought zinc and zinc alloys may be obtained as rolled strip, sheet and foil; extruded rod and shapes and drawn rod and wire.

These metals exhibit good resistance to corrosion in many types of service, and because the corrosion products that may form on them are white, other materials are not stained by them.

Wrought zinc has chemical characteristics particularly adapted to certain uses, such as dry batteries and photoengraver`s plate, and offers combinations of desirable physical and mechanical properties at relatively low cost.

In common with many other metals and alloys, wrought zinc creeps under constant loads that are substantially less than its ultimate strength that is, wrought zinc does not have clearly defined elastic module, and hence creep data from service tests must be used in designing for strength and rigidity under conditions of continuos stress.

All severe fabrication of wrought zinc should be done at temperatures above 20°C. Rolled zinc of the proper grade is readily drawn into a great variety of articles such as batter cups, eyelets, meter cases, novelties, flashlight reflectors and fruit-jar caps.

Suitable grades of rolled zinc also are readily rolled, press formed, stamped or spun into items such as plates for addressing machines, buckles, ferrules, ornaments, nameplates, gaskets, weather-stripping and lamp parts.

The ordinary grades of wrought zinc can be soldered easily by conventional methods. The usual precautions should be observed regarding proper cleaning and fluxing.

The metal must not be overheated to the point where it melts. Pulsed-arc welding may be used for joining; gas welding of zinc is used only for repair work.

Wrought zinc is easily machined using standard methods and tools. However, if it is necessary to machine zinc containing exceedingly coarse grains, the metal should be heated to a temperature between 70 and 100°C in order to avoid cleavage of crystals.

Wrought zinc has chemical characteristics particularly adapted to certain uses, such as dry batteries and photoengraver`s plate, and offers combinations of desirable physical and mechanical properties at relatively low cost. In common with many other metals and alloys, wrought zinc creeps under constant loads that are substantially less than its ultimate strength. The ordinary grades of wrought zinc can be soldered easily by conventional methods.

Zinc gravity casting alloys can be used for general industrial applications where strength, hardness, wear resistance or good pressure tightness is required. Zinc alloys often are employed to replace cast iron because of their similar properties and higher machinability ratings.

The good bearing and wear characteristics of zinc alloys permit them to be used for bearing bushings and flanges. Other applications in which zinc alloys have been successfully substituted for cast iron or copper alloys include fuel-handling components, pulleys, electrical fittings and hardware components.

pure Zinc is never used in casting due to it’s low strength. Today, all Zinc alloys supplied by reputable producers are made from primary of virgin Zinc which conforms to the SHG (super high grade) or Zn 1 brand which is quoted in commodity markets worldwide.

The corrosion protection is primarily due to the anodic potential dissolution of zinc versus iron. Zinc is acting as sacrificial anode for protecting iron (steel). While steel is close to -400 mV, depending on alloy composition, electroplated zinc is much more anodic with -980 mV. Steel is preserved from corrosion by cathodic protection. This enhances corrosion protection further. On the opposite Zn/Ni between 12% and 15% of Ni (Zn/Ni 86/14) has a potential around -680 mV closer to Cadmium -640 mV. Thanks to this mechanism of corrosion, this alloy offers much greater protection than all other alloys.

For cost reasons the existing market is dividing between alkaline Zn/Fe (99,5%/0,5%) and alkaline Zn/Ni (86%/14%). The former Zn/Ni (94%/6%) that was a blend between pure zinc and the crystallographic gamma phase of Zn/Ni (86%/14%), was withdrawn from the European specs. A specific advantage of alkaline Zn/Ni (86%/14%) involves the lack of hydrogen embrittlement by plating. This initial layer preventshydrogen from penetrating deep into the steel substrate thus avoiding the serious problems associated with hydrogen embrittlement.

Alloy Suppliers

Alloy Suppliers  Aluminum

Aluminum  Aluminum Extrusions

Aluminum Extrusions  Copper-Brass-Bronze

Copper-Brass-Bronze  Nickel

Nickel  Magnets

Magnets  Stainless Steel

Stainless Steel  Stainless Steel Tubing

Stainless Steel Tubing  Steel Service Centers

Steel Service Centers  Titanium

Titanium  Tungsten

Tungsten  Wire Rope

Wire Rope