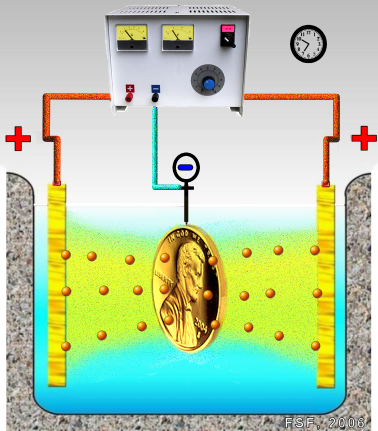

Electroplating is the process of using an electrical current to coat an electrically conductive object with a thin layer of metal. Copper plating is the process in which a layer of copper is deposited on the item to be plated by using an electric current.

Three basic types of processes are commercially available based upon the complexing system utilized :

- alkaline-(several modifications of cyanide and non-cyanide) complexed bath

- acid-(sulfate and fluoborate) complexed bath

- mildly alkaline-(pyro phosphate) complexed bath

With a higher current, hydrogen bubbles will form on the item to be plated, leaving surface imperfections. Often various other chemicals are added to improve plating uniformity and brightness. Without some form of additive, it is almost impossible to obtain a smooth plated surface. These additives can be anything from dish soap to proprietary compounds.

You might also like

| Electroplating Electroplating is the process of... | Nickel and Nickel Alloys Nickel is a chemical element, with... | Advanced Ceramics A ceramic is an inorganic, nonmetallic... | Metal Spraying Metal spraying is spraying hot metal... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope