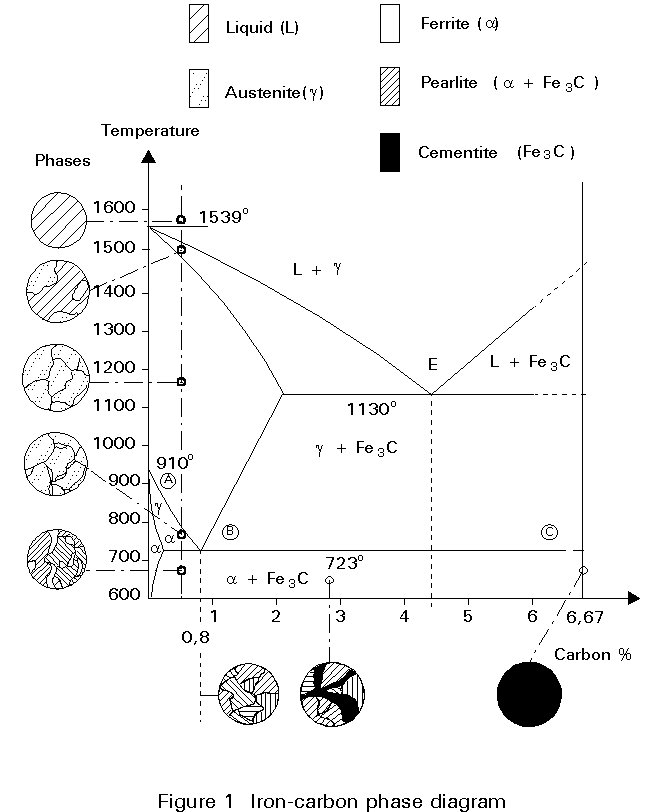

According to European standard EN 10 020, steel is a material which contains by weight more iron than any other single element, having a carbon content generally less than 2% and containing other elements (Figure 1). A limited number of chromium steels may contain more than 2% of carbon, but 2% is the usual dividing line between steel and cast iron.

Steel Wire

Steel Wire

Due to its high strength, its good machineability and its high economic efficiency, steel is one of the most important construction materials. By changes in the chemical composition and in the production conditions, it is possible to vary steel properties over a wide range and the steel manufacturer is able to adapt the properties to the specific requirements of users.

As well as chemical and mechanical properties, internal soundness, surface quality, form and geometrical dimensions can be important criteria for steel product users. The steels used for structural applications are mainly hot rolled in the form of sections, plates, strip, wide flats, bars and hollow sections. Such products may have undergone cold forming operations after hot rolling. Cast and forged material is also sometimes used.

In order to facilitate production, ordering and use of steel products, steel grades and qualities are listed in quality standards and specifications, giving chemical composition, mechanical and technological properties. This lecture deals with the classification of steel grades and gives an overview of the main grades used for structural steelwork.

CLASSIFICATION OF STEEL GRADES

The European standard EN 10020 classifies steel grades into:

- non-alloy and alloy steels by chemical composition

- quality classes defined by main property or application characteristics for non-alloy and alloy steels.

Classification by Chemical Composition

Classification is based on the ladle analysis specified in the standard or product specification, and is determined by the minimum values specified for each element.

- Non-alloy steels are steel grades for which none of the limit values in Appendix 2 is reached.

- Alloy steels are steel grades for which at least one of the limit values given in Appendix 2 is reached.

Classification by Main Quality Classes

Steel grades can be classified into the following quality classes :

Classes of non-alloy steels

- Non-alloy base steels

- Non-alloy quality steels

- Non-alloy special steels

Classes of alloy steels

- Alloy quality steels

- Alloy special steels

For this classification, the following points have to be taken into consideration:

- Chemical composition

- Mechanical properties

- Heat treatment

- Cleanness in terms of non-metallic inclusions

- Particular quality requirements, e.g. suitability for cold forming, cold drawing, etc.

- Physical properties

- Application

Details of this classification are given in the standard EN 10020.

The Main Points

A. Steel Manufacturing Process

The steel manufacturing process (Basic-Oxygen-Furnace, Electric-Furnace, etc.) is generally the option of the manufacturer.

For the deoxidation method, the following are possible :

- Optional : method at the manufacturer’s option.

- Rimming steel (no addition of deoxidation elements). This type of steel is used only for steels with low yield strengths and no special toughness requirements.

- Rimming steel not permitted: the manufacturer may deliver either semi-killed or killed steel.

- Fully killed steel containing nitrogen binding elements in amounts sufficient to bind the available nitrogen, e.g. minimum 0,020% Al.

B. Delivery Conditions

Several supply conditions are allowed :

- Supply at the manufacturer’s option.

- Hot-rolled i.e. as-rolled.

- Thermomechanical treatment: Normalizing forming (N)

Thermomechanical forming (TM).

- Normalized (N).

It should be noted that quenched and tempered steels are not discussed in this lecture. The definitions for thermomechanical treatment of steels are given in Appendix 3. The supply condition of the product is very important with respect to the application of the steel. This condition should, therefore, be clearly stated in the order. Particular attention must be paid to normalized (N), or normalizing formed (N) products and thermomechanically formed steels (TM). Thermomechanically formed material, unlike N-material, is not suitable for subsequent heat-treatment (except stress-relieving) or hot deformation (1100°C). Treatment of TM-steels at high temperatures leads to a decrease in strength.

It should be noted that TM-treated material has the following advantages compared to N-steels of the same grade:

- Lower content of alloying elements.

- Better weldability due to a lower carbon equivalent.

- Lower cost.

- Time saving due to the in-line treatment.

- No product length limitations.

C. Chemical Composition

The requirements are based on the ladle analysis and not on the product analysis. If a product analysis is specified, the permissible deviations of the product analysis from the specified limits of the ladle analysis have to be considered.

D. Mechanical Properties

Quality standards generally specify tensile and notch toughness properties.

Tensile properties

The required values depend on the material thickness. Yield strength and tensile strength decrease with increasing thickness, which can be explained by the fact that for thicker material the grain refinement during rolling is smaller.

Notch toughness properties (impact test)

The test temperature and the minimum absorbed energy are specified.

Sampling direction

The mechanical properties can be specified for the longitudinal and/or for the transverse direction. Longitudinal means parallel to the rolling direction, transverse is perpendicular to the principal rolling direction. During the hot rolling of long products the deformation takes place mainly in one direction creating an anisotropy which results in different mechanical properties in the longitudinal and the transverse directions. The difference is most marked in ductility (elongation, notch toughness).

E. Technological Properties

Technological properties include weldability and formability.

Weldability

Weldability, which is a very important property of structural steels, is judged on the basis of :

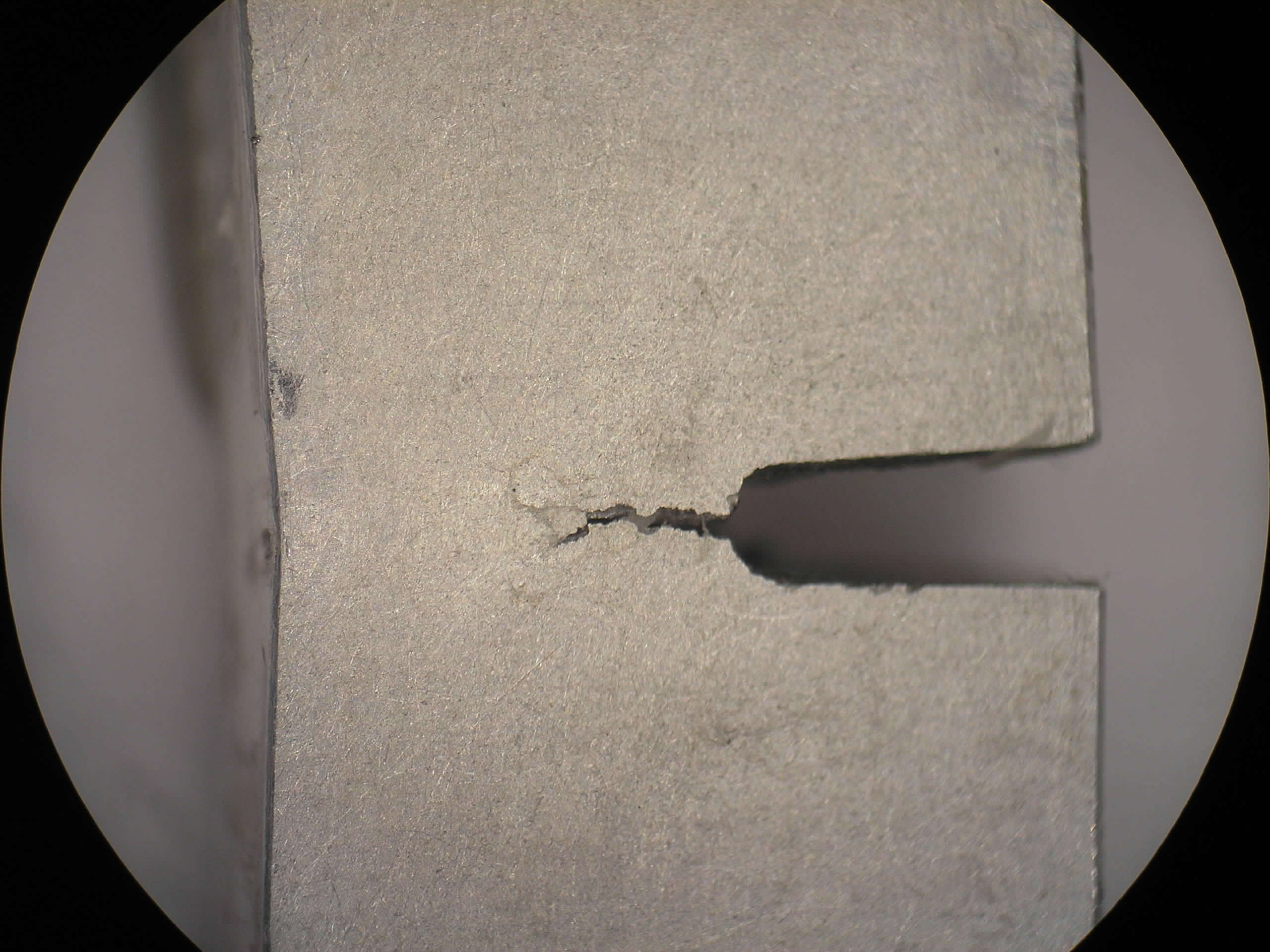

a. tendency to cold cracking

b. toughness of the heat affected zone

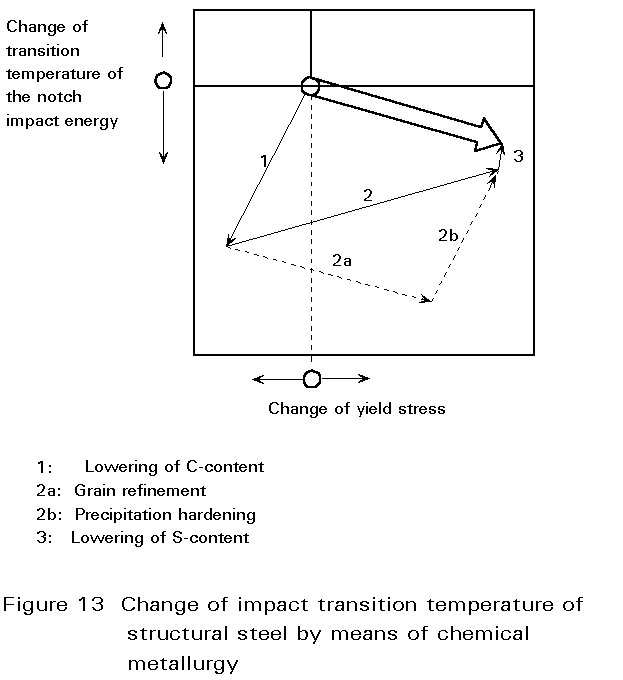

Weldability is influenced by the chemical composition and by the metallographic structure of the steel. By increasing the content of alloying elements the weldability is decreased. An improvement in weldability is obtained by grain refinement. Weldability generally decreases with increasing tensile strength which is related to the higher content of alloying elements in the higher strength steels.

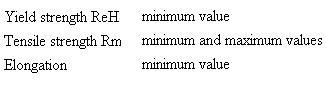

Figure 2 shows the influence of composition on weldability. Rate of cooling increases susceptibility to cold cracking and is controlled by the combined thickness of the heat paths away from the weld, the vertical axis on the graph. Arc energy, the horizontal axis on the graph, also influences cooling rate; the higher the heat input the longer it will take to cool. The graph shows how reducing the carbon equivalent increases the range of conditions which can be welded with a particular preheat, in this instance 100°C, and a particular welding process, in this instance MAG with conventional wire electrodes.

Formability

Structural steels are suitable for hot and cold forming. It should be noted that thermomechanically treated steels should not be used for hot forming. Cold formability includes flangeability, roll forming and drawing of bars. Cold formability is evaluated by bend tests. The specified inside bending radius increases with increasing material thickness and tensile strength. The bend test samples can be taken in the longitudinal or transverse direction.

F. Surface finish

The steel product should be free from such defects as would preclude its use for the purpose for which it is intended.

G. Inspection and testing

The quality standards specify :

- Type of test (tensile, impact, bend, chemical analysis, etc.).

- Batching: the verification of the mechanical properties can be carried out by lot (e.g. one test for every 20, 40 or 60 products) or by melt.

- Inspection units: number of tests per batch.

- Position of the test samples : according to Euronorm 18 (see Figure 3).

- Selection and preparation of test pieces.

Steel products shall be marked by painting, stamping or durable adhesive labels with the following information:

- Steel grade.

- Heat number.

- Manufacturers name or trademark.

You might also like

| Optimal Combination of STRENGTH and TOUGHNESS Preceding sections have described the influence... | Failure analysis Failure analysis is the process of... | Austempered Ductile Iron (ADI) Austempered Ductile Iron (ADI) is... | Fracture Mechanics Concepts The basis of a fracture mechanics safety... |

Alloy Suppliers

Alloy Suppliers

Aluminum

Aluminum

Aluminum Extrusions

Aluminum Extrusions

Copper-Brass-Bronze

Copper-Brass-Bronze

Nickel

Nickel

Magnets

Magnets

Stainless Steel

Stainless Steel

Stainless Steel Tubing

Stainless Steel Tubing

Steel Service Centers

Steel Service Centers

Titanium

Titanium

Tungsten

Tungsten

Wire Rope

Wire Rope